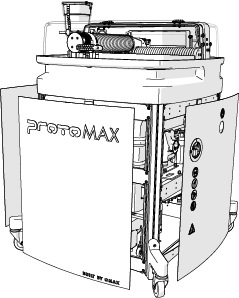

ProtoMAX®

Maintenance Guide

|

OMAX Corporation |

|

Information:

|

info@protomax.com |

This document contains subject matter to which OMAX® Corporation has proprietary rights. Recipients of this document shall not duplicate, use, or disclose information contained herein, in whole or in part, for any use other than the purpose for which this manual was provided.

OMAX Corporation believes the information described in this manual is accurate and reliable. From time to time, design improvements will be made to the OMAX equipment. Photographs, text, and sketches within the body of this manual may not exactly represent your equipment. In general, this manual contains the most up-to-date information available. However, OMAX Corporation cannot accept any responsibility, financial or otherwise, for any consequences arising out of the use of this material. The information contained herein is subject to change, and revisions may be issued to advise of such changes or additions. OMAX strives to continually improve user documentation. If you have any questions or concerns about the content of this user’s guide, please e-mail us at tech_writing@omax.com, or contact us by mail at:

OMAX Corporation

Technical Publications

21409 72nd Avenue South

Kent, WA, USA 98032

OMAX Corporation is continually improving their equipment to bring you the best in abrasive waterjet machining technology. For that reason, your abrasive waterjet may differ slightly from what is described in this document. If you have any questions, please feel free to contact us at 1-800-838-0343 or e-mail us at support@protomax.com. You can also receive technical support on-line at: Web: https://www.protomax.com.

Original Instructions in English

June 2020

©2020 OMAX Corporation

Important Safety Information

SAFETY IS YOUR RESPONSIBILITY.

For your own safety, read this guide thoroughly and carefully before the equipment is installed, operated, maintained, or issues are troubleshooted.

Save these instructions.

This guide contains important safety information for the equipment. Careful compliance with the safety information helps prevent physical injury, damage to the equipment, and can extend the equipment's life.

Equipment safety features, safety glasses, hearing protection, and more can reduce potential injury. Be careful when the equipment is installed, operated, and maintained. Safety guards and features do not guarantee your safety if you are careless, inattentive, or use poor judgment. If it feels dangerous, do not try it.

YOU ARE RESPONSIBLE FOR YOUR SAFETY IN YOUR SHOP.

Machine Safety Labels

These safety labels can appear on the equipment. If ignored, physical injury, death, or equipment damage may occur. Read the complete safety information in the operation, installation, or maintenance guide before the equipment is installed, operated, or maintained.

WARNING Electrical Shock

Dangerous voltages. Do not access areas with this label before the applicable safety precautions are done; lockout/tagout the power and make sure there is no voltage on the circuits before installation, maintenance, or other work is done.

WARNING Airborne Debris

Eye protection and hearing protection are required during operation. Do not remove the abrasive feed tube from the nozzle or hopper when pressurized. The pressure can blow abrasive into the air, and the abrasive particles can get into the eyes and contaminate tools and machines.

WARNING Keep Fingers and Hands Away From Parts that Move

Keep hands and fingers away from the machine when it moves and during operation. Fingers and hands can be crushed and cut by machine parts when they move. Do not try to gain access to the machine or parts during operation.

WARNING Pinch Risk

Keep hands away from the edge of the catcher tank when the lid is closed.

WARNING Keep Hands Away From Jet

Do not put hands or fingers near the nozzle during operation. Immediately get medical aid for abrasive waterjet injuries. Injuries caused by high-pressure abrasive waterjet systems are dangerous. Do not wait to get medical aid!

WARNING Watch Hands and Fingers

Always keep the motor guards in position during operation. Keep hands away from belts and pulleys during maintenance and service.

Electrostatic Discharge

Attention! Be careful when electrostatic-sensitive devices are touched. Use electrostatic discharge protection procedures.

No Open Flame

Do not smoke near the equipment. Do not operate the equipment in an explosive atmosphere. Make sure ignition sources (such as flames or electrostatic discharge) are not near the equipment. Do not store flammable materials near the equipment. Do not use equipment in or around flammable gases or liquids. Do not let explosive or flammable vapors collect in the area around the equipment. Make sure there is good airflow in the work area to dissipate gases, vapors, and fumes. Be especially careful when machining materials that create sparks, such as titanium, which can cause gases in the catcher tank to explode.

Do Not Operate With Guard Removed

Do not operate when the guards or panels are removed.

Do Not Spray

Do not spray water on or near the machine's electrical enclosure.

Do Not Step

Do not step, stand, or walk on the slats. The slats can become weak after operations and can fall under more weight.

Read Manual First/Do Not Adjust

Do not adjust. Read the manual. Special instructions could be required before adjustments are made. Adjustments to the equipment can have unwanted effects and cause injury or damage.

MANDATORY ACTION Disconnect Power

Always disconnect the primary power cord from the electrical source to isolate the machine from its electrical supply.

Read Manual

Read the equipment operation guide for important safety information and operation instructions. Do not operate this machine until all safety precautions and operation instructions are read and understood.

Wear Hearing Protection

Always wear hearing protection when near the equipment during operation. When operated above water, noise levels can exceed 70 dBA.

Wear Eye Protection

Always wear approved safety glasses when the abrasive waterjet system is operated. Other types of glasses do not give sufficient eye protection! The garnet abrasive is not a chemical irritant, but garnet can cause an eye injury like sand if it is not quickly flushed. Also, the catcher tank water can contain particles from the material or other chemical irritants. Have an eye-wash station near the work area if the abrasive spray gets into the eyes.

Read the product labels and refer to product Safety Data Sheets (SDS) to identify the properties and risks of chemical products and materials referenced in this document. Use good industrial hygiene, safety practices, and personal protective equipment identified in the SDS.

Wear Gloves

The catcher tank water can have dangerous bacteria in it. A small break in the skin can introduce the dangerous bacteria into a wound. Always wear protective gloves if there are cuts or wounds on the hands or fingers. When material is put on or removed from the slat bed, wear gloves that give protection against sharp metal edges.

Read the product labels and refer to product Safety Data Sheets (SDS) to identify the properties and risks of chemical products and materials referenced in this document. Use good industrial hygiene and safety practices. Use personal protective equipment as specified in the SDS.

Safety Precautions

Safety instructions must be followed when the equipment is installed, operated, or maintained. If ignored, death or physical injury can result, or damage can occur to the equipment. Always follow the applicable safety precautions when work is done with this equipment.

Use the equipment ONLY for its intended function

- Read the installation manual before the equipment is set up to learn about important installation and safety information.

- Read the documentation for recommended accessories. The use of incorrect accessories can cause a risk of injury to persons or damage to equipment.

- Wear eye and hearing protection. Always wear ISO-approved impact safety glasses.

- Make sure the equipment is installed correctly before the system is started.

- Never stand on the equipment. Serious injury can occur if the machine tips or you touch the machining tool during operation.

Do not make changes

- Do not make changes to the equipment or components that are not approved.

- Changes to the equipment can cause a risk of physical injury to the operator and others and can cause damage to the equipment or other property. Changes to the equipment will void the warranty.

- Do not change, defeat, or bypass the equipment safety features.

Do not remove panels

- Do not remove the panels during operation. Only remove them when required by maintenance or to troubleshoot problems.

Check for damaged parts

- Before the equipment is used, carefully examine guards or other parts that are damaged to make sure that it operates correctly and functions as intended. Examine to make sure parts that move, move freely, are aligned correctly, are not broken, are mounted correctly, and for other conditions that can have an effect on its operation. Replace guards or other damaged parts.

Use caution, stay alert, and be attentive

- Do not install, operate, or service the equipment while under the influence of alcohol or drugs. Read the warning labels on prescription and over-the-counter drugs. If in doubt, do not install or operate the machine.

- Do not install, operate, or service the equipment when you are tired.

- Always follow the safety precautions when the equipment is installed, operated, maintained, or serviced. Carefully operated, the abrasive waterjet is a safe tool. When operated carelessly, serious injury can result.

- Wear a face or dust mask.

- Do not reach over the machine to operate it. Keep feet on the floor and balanced at all times.

- Keep a minimum of 16 in. (40 cm) away from pressurized equipment during operation.

- Do not try to tighten the ultra high-pressure (UHP) fittings when the system is pressurized.

Keep the tools and equipment in good condition

- Keep machine and accessories clean for the best and safest performance.

- Always keep the equipment in good condition.

- Follow the maintenance instructions for equipment and accessories.

- Keep all protective guards and stop devices.

Keep the equipment and area around the equipment clean and free from clutter

- Remove all installation, operation, or maintenance tools from the equipment before it is operated.

- Keep the work area clean and clutter-free to prevent accidents.

- Keep the equipment clean for the best performance.

Do not operate the equipment in a dangerous environment

- Do not use the equipment in or around flammable gases or liquids.

- Do not expose the equipment to rain or use it outdoors.

- Keep the equipment in a bright work area.

Never leave the equipment unattended during operation

- Always stop and turn off the equipment before leaving the area.

- Keep visitors at a safe distance from the work area.

- Keep children away from the equipment work area.

- Do not let children play around or operate the equipment or its components.

Never operate the equipment without safety guards or covers

- Do not change, bypass, or try to defeat the safety guards, covers, or switches.

- Keep the guards in position and in working order.

- Do not remove the safety cover or guard during operation.

- Know the location of the ON/OFF switch.

- Know how to disconnect the primary power supply to the equipment.

- Start and operate the machine only when all side panels are in position.

Never put your hands in the area of the nozzle during operation

- Seek immediate medical aid for all waterjet injuries. Injuries caused by high-pressure abrasive waterjets are serious. Do not wait!

- Refer to the WaterJet Technology Association (WJTA) warning card for important medical aid information.

Figure 451

Be careful when material(s) is moved in the catcher tank

- Do not operate the equipment when material is moved into the catcher tank.

- Always stop the abrasive waterjet before adjustments are made to the material or the abrasive jet.

- Always be careful when material is moved into the catcher tank. Fingers can be caught between a heavy part and the support slats.

- Be careful around the support slats. The abrasive waterjet also cuts the support slats; the edges can become sharp and cause cuts or collapse.

Do not touch live electrical components or parts

- Always use a licensed electrician or approved person to install the primary power source to use with the machine.

- Examine the equipment power and control cables regularly for correct connection and installation. Damaged, exposed, and bare wires can cause electrocution or death!

- Make sure the equipment is correctly connected and grounded in accordance with the national, state, and local codes. Do not remove the prongs from the plug. Always plug into the correct electrical outlet.

- Never use any electrical plug adapter.

- Make sure the power switch is in the OFF position before the equipment is plugged in to stop accidental starts.

- Always disconnect the equipment from the primary power before service or maintenance work is done.

Noise Emission Precautions

Environmental factors, such as how the room or structure is built, other machines and power tools in the area, and other noise sources, can have an effect on the environment's true noise level. When installed and operated correctly, the equipment's A-weighted emission sound pressure level, LpA , is less than 75 dBA (LpA < 75 dBA). Therefore, OMAX recommends that the operator wear hearing protection during equipment operation.

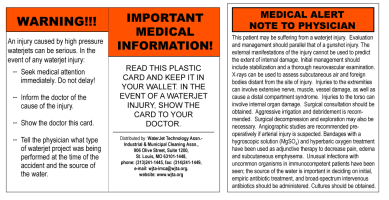

Treat All Injuries with Caution

Injuries that involve contact with the catcher tank water should receive medical aid immediately. Refer to the WJTA Warning Card for important medical aid information.

Get medical aid immediately for an abrasive waterjet injury. Tell the physician the cause of the injury, the type of abrasive waterjet work that was done when the accident happened, and the water source.

Stagnant water in the catcher tank can introduce dangerous bacteria into cuts, scrapes, small breaks in the skin, and other types of wounds. Injuries that involve contact with the catcher tank water should receive aid immediately. Injuries that involve contact with the water should be attended to immediately.

Unusual infections with aerophilic microorganisms that occur at lower temperatures have been reported. These can be gram-negative pathogens, such as those found in sewage. Bacterial swabs and blood cultures may be helpful to assist a physician's diagnosis.

An injury caused by high-pressure waterjets can be dangerous. If there is a waterjet injury:

- Get medical aid immediately. Do not wait!

- Tell the physician of the cause of the injury.

- Tell the physician about the type of abrasive waterjet work done when the accident happened and the water source.

- Give this information to medical personnel:

This patient may be suffering from a waterjet injury. Evaluation and management should parallel that of a gunshot injury. The external manifestations of the injury cannot be used to predict the extent of internal damage. Initial management should include stabilization and a thorough neurovascular examination. X-rays can be used to assess subcutaneous air and foreign bodies distant from the site of injury. Injuries to the extremities can involve extensive nerve, muscle, vessel damage, and cause a distal compartment syndrome. Injuries to the torso can involve internal organ damage. Surgical consultation should be obtained. Aggressive irrigation and debridement is recommended. Surgical decompression and exploration may also be necessary. Angiographic studies are recommended pre-operatively if arterial injury is suspected. Bandages with a hygroscopic solution (MgSO4) and hyperbaric oxygen treatment have been used as adjunctive therapy to decrease pain, edema, and subcutaneous emphysema. Unusual infections with uncommon organisms in immunocompetent patients have been seen; the source of the water is important in deciding on initial, empiric antibiotic treatment, and broad-spectrum intravenous antibiotics should be administered. Cultures should be obtained.

Lockout/Tagout

Do standard practices and procedures to shutdown and stop the equipment, isolate it from its energy source(s), and prevent the release of potentially dangerous energy when maintenance and service work is done.

Equipment Grounding Requirements

- Make sure the equipment is correctly grounded in accordance with the national, state, and local codes. Do not remove the prongs from the plug. Always plug into the correct electrical outlet.

- The ground wire gives the electric current a path of least resistance to reduce the risk of electrical shock during a malfunction or breakdown. The machine has an electric cord with an equipment-grounding conductor (EGC) and a ground plug (United States, Canada, and Mexico only). The plug must be connected to a matching outlet that is correctly installed and grounded in accordance with all local codes and ordinances.

- Do not change the plug—if it does not fit the outlet, have the correct outlet installed by a qualified electrician.

- If the EGC is incorrectly connected, it can result in electric shock.

- Contact a qualified electrician or service personnel if the grounding instructions are not understood or if not sure if the equipment is correctly grounded.

- Do not use extension cords with the equipment.

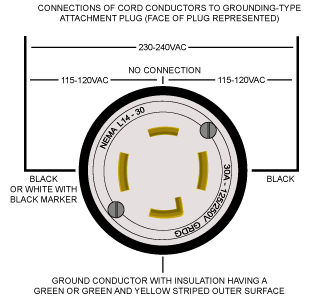

- If the cord is damaged or worn, immediately replace it. Contact OMAX for replacement parts and instructions. The insulation of the EGC is covered with a green or green with yellow-striped surface. If replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor to a live terminal. Refer to the equipment-specific wiring configuration.

- The equipment is intended to be used on a circuit with an outlet similar to the one shown (United States, Canada, and Mexico only):

Figure 452

- The grounding plug is similar to the one shown (United States, Canada and Mexico only):

Figure 453

- Make sure that the equipment is connected to an outlet that matches the plug configuration.

- The equipment must not be connected to any different type of electric circuit.

- No adapter is available or should be used with this equipment.

- For countries other than the United States, Canada, and Mexico, OMAX does not supply a sufficiently rated industrial-grade plug.

- Contact a qualified electrician or service personnel to install a sufficiently rated industrial-grade plug in accordance with national, state, and local codes.

- A pin and sleeve plug, rated at least 30A, 230V, 2-pole+E (3-wire grounding), IP44 or better, having a first-make last-break protective bonding contact (earthing contact) in accordance with standards IEC 60309-1 and IEC60309-2 can fulfill this requirement.

Figure 454

- The cord must be plugged into a matching outlet that is correctly installed and grounded in accordance with all local codes and ordinances.

Figure 455

Explosive Atmosphere Precautions

Machining certain types of material, such as titanium, with a waterjet can cause sparks. Do not operate the equipment in an explosive environment. Do not let explosive or flammable vapors collect in the area of the equipment.

Removal of Waste Materials

Discard all machining wastes correctly in accordance with all local and federal regulations. Abrasive waterjet machining causes two types of waste: the water used for machining and the solid material that collects in the catcher tank. Although the used garnet abrasive is not dangerous, the waste deposited from the cut material can require special treatment.

In abrasive waterjet machining, high-pressure water with garnet abrasive particles hits and cuts the material. The abrasive grit and eroded particles from the cut material collect and settle at the bottom of the catcher tank until discarded. Different materials can have different requirements to discard them correctly. Always refer to all local and federal regulations. For example, when poisonous materials such as lead or radioactive metals are cut, the correct steps must be taken to discard the poisonous or radioactive water, material debris, and used abrasive garnet; local and federal regulations must be followed. Always refer to the local utility company for sewage or water treatment requirements and procedures to discard waste materials.

Sufficient Shop Ventilation

Make sure there is good airflow in the work area to dissipate gases, vapors, and fumes. The machine contains a large amount of water. The ambient temperature in the shop and of the water can have an effect on water evaporation. To decrease the effect on other equipment in the shop, make sure there is good airflow in the shop. Also, some materials, such as aluminum particles, are known to make hydrogen in water.

When aluminum is cut, the small particles of aluminum dust in the catcher tank react with the water to make flammable hydrogen gases. Usually, hydrogen bubbles to the surface and is released into the shop in safe, low concentrations.

Make sure no ignition sources (open flame or electrostatic discharge) are near the abrasive waterjet system.

Monitor the catcher tank for hydrogen gas bubbles when large quantities of aluminum are cut. The aluminum powder (made from the removed material) and spent garnet collect at the bottom of the catcher tank. The aluminum then reacts with the water and releases hydrogen gas. The hydrogen gas can collect in bubbles in the garnet. The hydrogen gas bubbles are flammable. Keep the garnet levels in the catcher tank low to prevent hydrogen gas bubbles from being collected within the garnet.

Do not smoke near the machine. Keep other sources of ignition or flammable materials near the machine. Be careful when materials that create sparks are cut, such as titanium, which can fire the gases in the catcher tank and cause an explosion. Remove the aluminum powder from the catcher tank before machining materials that spark.

Overpressure Protection

During operation, pump pressure is monitored to prevent an overpressure condition. If the pump pressure increases more than the factory-set maximum pressure limit, the safety relief valve starts and stops the pump.

Electrical Protection

The equipment controller includes short circuit, overcurrent, and thermal protection for the pump motor.

Electrical Disconnect/Emergency Machine Off (EMO)

An electrical disconnect/emergency machine off (EMO) switch is used to remove the primary AC electrical supply from the machine. To isolate the machine from its electrical supply, always unplug the primary AC supply power cord from its electrical supply outlet.

Safety Lid

The lid of the equipment has a safety interlock to prevent waterjet operation when the lid is open.

Safety Legend

The safety signal word panels and paragraph notifications can be shown throughout this and other documentation. Each gives the safety issue identification and recommended actions to prevent the risk. Be alert! Follow the recommended safety steps, procedures, and precautions to prevent injury or damage to the equipment.

Identifies a dangerous situation that could result in death or serious injury if not avoided.

Identifies a dangerous situation that could result in minor or moderate injury if not avoided.

Identifies situations that are important but not dangerous or related to physical injury; for example, messages related to property damage.

Used to give information, emphasize a point, or tips for easier operation.

Required Tools

The following table contains a list of tools with the appropriate sizes that are needed to maintain the ProtoMAX. Tools listed with part numbers are included with the ProtoMAX or are available for purchase. Contact technical support for more information.

Additional tools needed to operate and maintain this equipment are in the applicable equipment guides.

| Icon | Tool | Size(s) |

|---|---|---|

|

|

Safety glasses | |

|

Open-end wrench | 1/2 in, 5/8 in., 3/4 in., 13/16 in., 1 in., 10 mm, 17 mm, 19 mm |

|

Torque wrench | 15–102 in-lb (2–12 N·m), 50–75 ft-lb (68–102 N·m) |

|

|

Crowfoot | 5/8 in., 13/16 in., 1 in., 19 mm |

|

Allen wrench | 1.5 mm, 3 mm, 4 mm, 5 mm |

|

Bucket | 1 gal |

|

Funnel, wide mouth | |

|

|

Shop rags | |

|

|

Blue Goop® (P/N 302692) |

|

|

|

Acid brush | |

|

Synthetic grease, electrical insulating (P/N 203996) |

|

|

|

Stand-off tool (P/N 317876) |

|

|

|

Screwdriver, flat | #2 |

|

Filter wrench (P/N 208885) |

|

|

|

Grease, silicone (P/N 209100) |

0.5 oz |

|

|

Gloves, safety | |

|

|

Soft blow mallet | |

|

|

Scrub brush | |

|

|

Hex socket | 3 mm, 4 mm, 5 mm |

|

|

Anti-seize compound | |

|

|

Spray bottle | |

|

|

Gloves, latex | |

|

|

Grease syringe P/N 309325 (prefilled with 204248 grease, synthetic, molydisulfide, NLGI 1-1/2, jetlube) |

|

|

|

Grease gun (P/N 318411) |

|

|

|

Strainer | |

|

|

Hand shovel | |

|

|

Brush, long flexible handle | |

|

|

Seal removal tool (P/N 316852) |

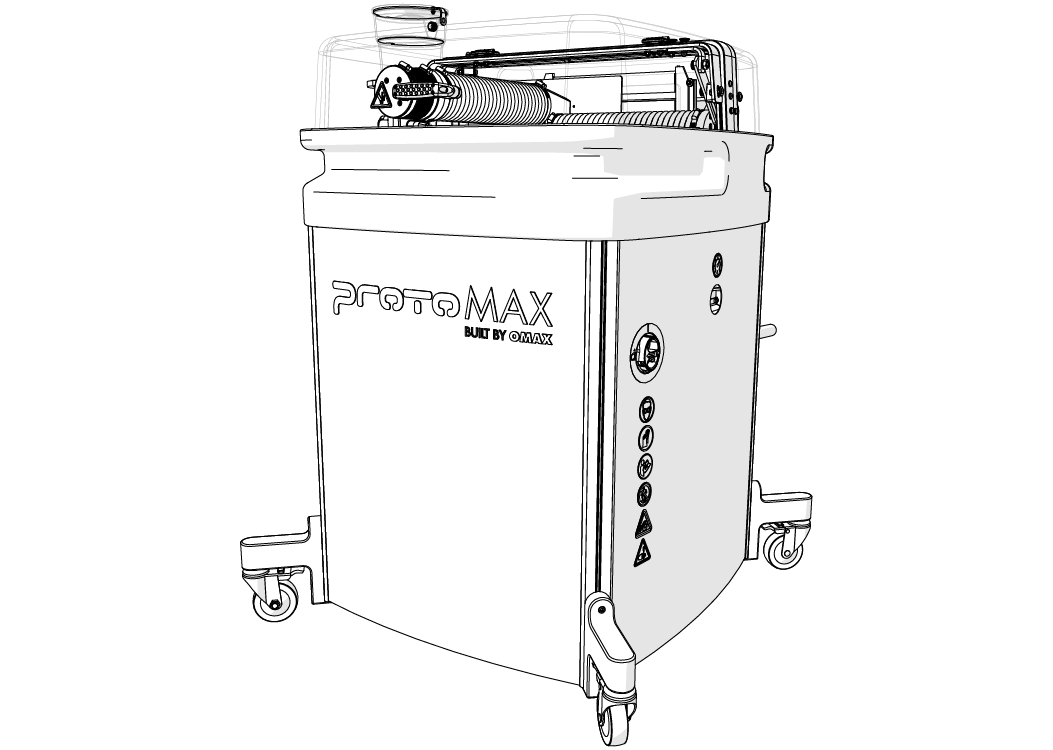

Introduction

Always follow the safety instructions presented in the Safety section to prevent serious injury or death.

This guide provides information and instructions needed to maintain the abrasive waterjet system. Follow the recommended Maintenance Schedule to maintain the system. It is important to inspect parts for wear or damage and to replace them as needed.

Maintenance Schedule

The following maintenance activities and schedules are provided to aid in the development of a successful maintenance program. After any maintenance procedure, flush the high-pressure lines. Use the maintenance log to record all performed maintenance to ensure a clean and efficient abrasive waterjet system.

| Task | Frequency | Reference |

|---|---|---|

| Pump maintenance | ||

| Change the crankcase oil | After the first 50 hours of operation | Change the Crankcase Oil |

| Annually, at pump rebuild, or every 250 hours after the first oil change | ||

| Inspect the wet end | Periodically for evidence of leaking, contact technical support if leaking | Inspect the Pump Wet End |

| Inspect/replace the safety valve | When leaking | Correct Safety Valve Water Leaks

Replace the Safety Valve |

| Water filtration maintenance | ||

| Change the water filter | When the filter gauge approaches 25 psi or lower while the pump is running | Change the Water Filter Cartridge and O-Ring |

| Inspect the filter housing O-ring | Periodically, replace every two years or if leaking | Change the Water Filter Cartridge and O-Ring |

| Table maintenance | ||

| Wash away garnet abrasive accumulation from equipment | Daily and as often as required to maintain a clean working environment | Remove the Accumulated Garnet

Clean the Cutting Stage |

| Remove all garnet, sludge, and slugs from the tank bottom | Whenever garnet abrasive reaches the bottom of the garnet collection bins or when excessive water turbulence is noticed during cutting | Clean the Catcher Tank |

| Empty and clean the garnet bins | When the garnet bins are full or as garnet accumulates in the bins | Clean the Garnet Bins |

| Inspect and clean the lid | As needed to ensure visibility of the cutting stage | Clean the Lid |

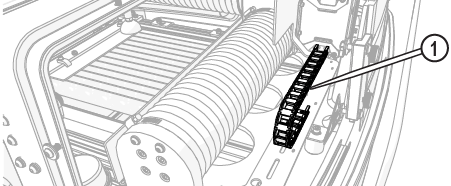

| Inspect and clean the cable track | Periodically to prevent the build-up of garnet or other debris that would cause the cables or the track to wear | Clean the Cable Track |

| Clean the catcher tank filters and drains | As needed or when water flow is restricted, replace when worn, or water flow is restricted | Clean the Catcher Tank Filters and Drains |

| Clean the frame and side panels | As needed | Clean the Frame

Clean the Side Panels |

| Inspect and replace individual slats | Rotate monthly or more frequently if needed; replace when excessively scored and no longer stable | Rotate or Replace the Slats |

| High-pressure lines and components | Replace if damaged or if continued leaking occurs; do not try to repair | Maintain the High-Pressure Lines and Components |

| Lubricate the X- and Y-axis lead screws and linear rails | Annually or if squeaking; inspect the lead screw for dirt or damage, inspect the linear rails for dirt or damage; clean and grease if need | Lubricate the Y-axis Lead Screw and Linear Rail Bearing Carriage

Lubricate the X-axis Lead Screw and Linear Rail Bearing Carriages |

| Replace the electrical enclosure air filters | Approximately once per month, or more frequently if required based on shop conditions to maintain adequate airflow or temperature | Change the Electrical Control Enclosure Air Filter |

| Nozzle maintenance | ||

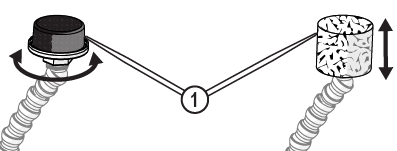

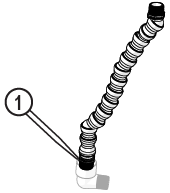

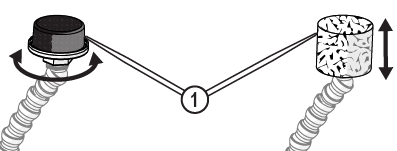

| Inspect the abrasive tubing | Before use, replace as needed | Replace the Abrasive Tubing |

| Clean the jewel orifice assembly and nozzle body | Once a week to prevent mineral buildup | Clean the Orifice and Nozzle Body |

| Change the nozzle filter and inspect, clean and replace the inlet body O-ring | After approximately 40 cutting hours or more frequently if needed | Replace the Nozzle Filter |

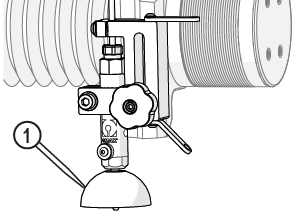

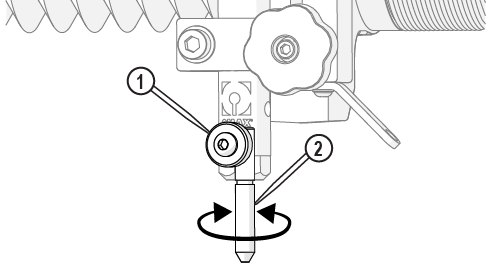

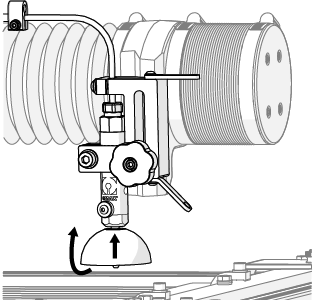

| Rotate or replace the nozzle mixing tube | Rotate 90 degrees (one-quarter turn) every 8 hours of cutting to even out wear; replace as needed | Rotate or Replace the Mixing Tube |

| Inspect and replace the nozzle splash guard | As needed when cracked, torn, or damaged | Rotate or Replace the Mixing Tube |

| PC Controller maintenance | ||

| Clean the keyboard | Daily or as needed | Per PC manufacturer instructions |

| Clean the monitor screen | As needed for sharp viewing | Per PC manufacturer instruction |

| Restart the laptop | Daily | Per PC manufacturer instruction |

| Update the ProtoMAX software | When OMAX releases updates | Download from the ProtoMAX website |

| Other as specified in the PC User's Manual (provided by the manufacturer | PC manufacturer-recommended | Per PC manufacturer instruction |

Maintenance Log

| Run Hours | Maintenance Performed | Done By | Date |

|---|---|---|---|

Pump Maintenance

This section contains procedures for performing the recommended pump maintenance. See the Maintenance Schedule for the recommended frequency for this task.

Always wear safety glasses when performing maintenance on the machine.

Prepare the Pump for Maintenance

| 5. | Turn OFF the machine. |

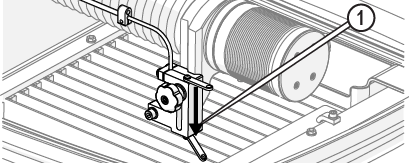

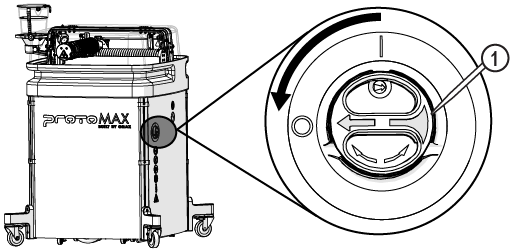

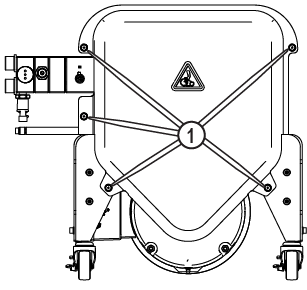

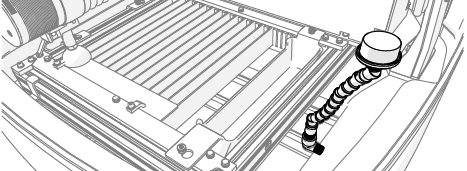

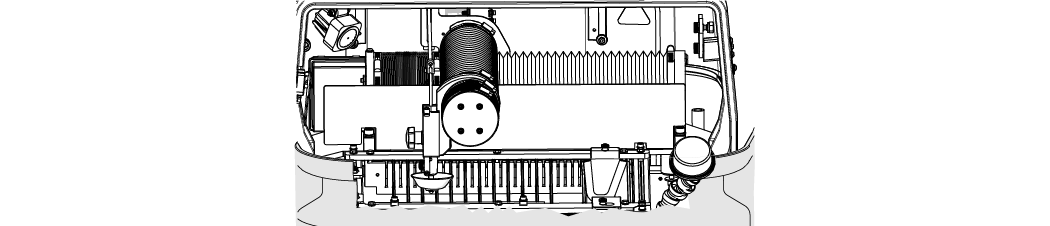

Figure 456

| 6. | Disconnect the power cord from the electrical outlet. |

| 7. | Turn OFF the water supply. |

| 8. | Ensure there is no pressurized water in the high-pressure lines. |

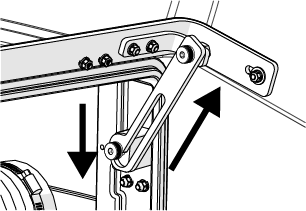

| a. | Open the lid and lock it in the upright position. |

Use care when opening or closing the lid to avoid injury. Never let the lid free-fall. Keep hand, fingers, or body parts away from the side of the table when closing the lid.

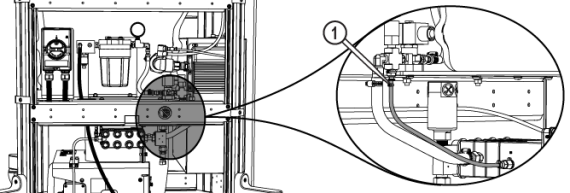

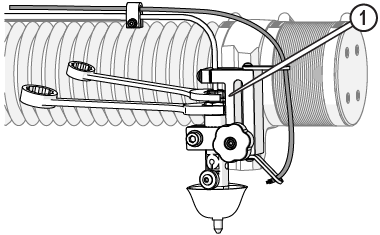

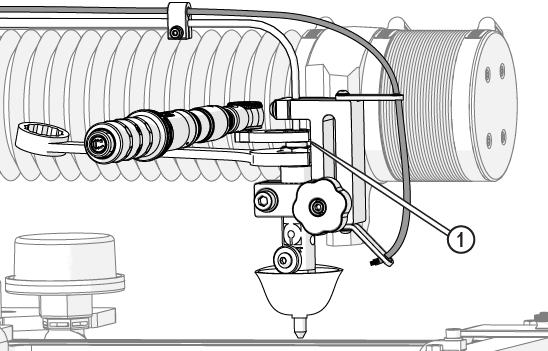

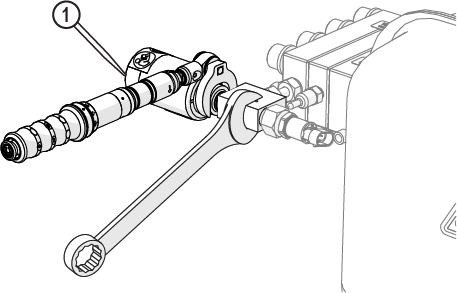

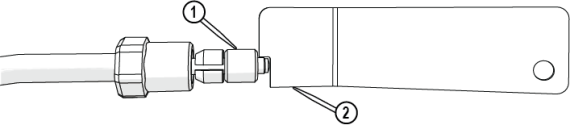

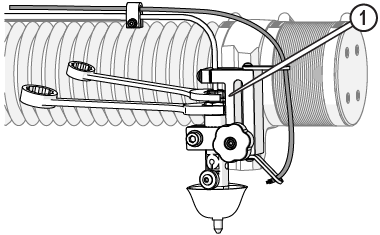

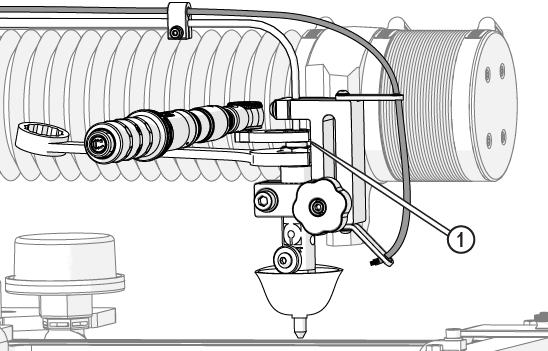

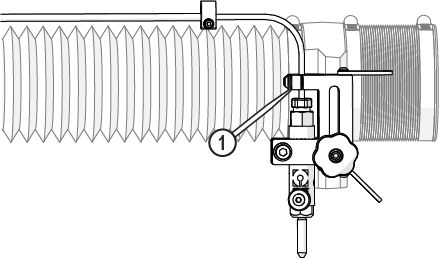

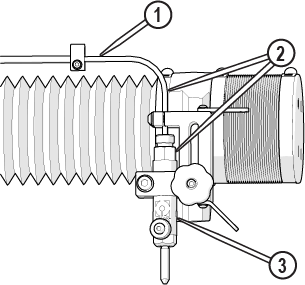

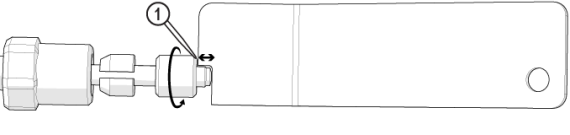

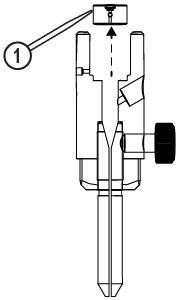

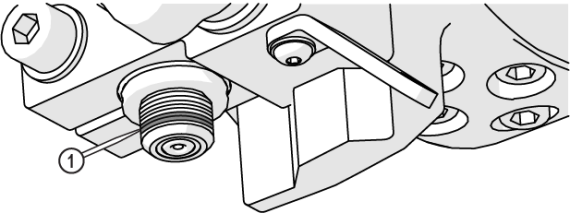

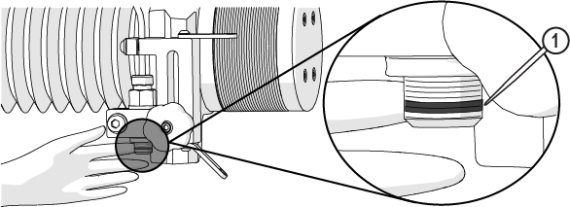

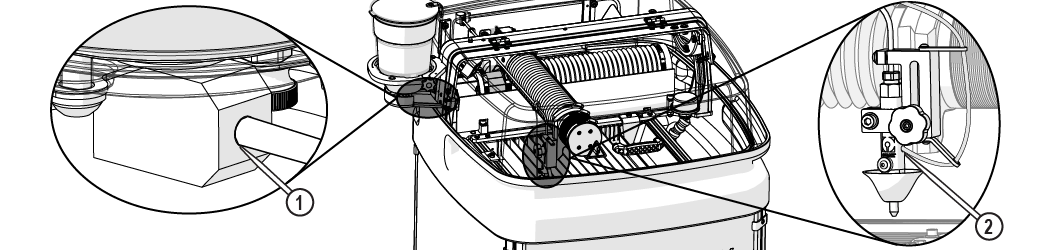

| b. | Loosen the gland nut [1] to release the pressure; water can leak from the inlet body weep hole. |

Figure 457

| c. | Tighten the gland nut [1]. |

Figure 458

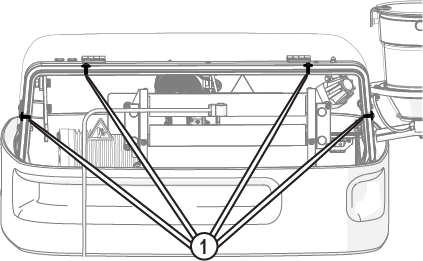

| 9. | Remove the side panels. |

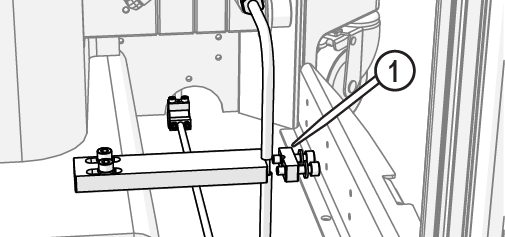

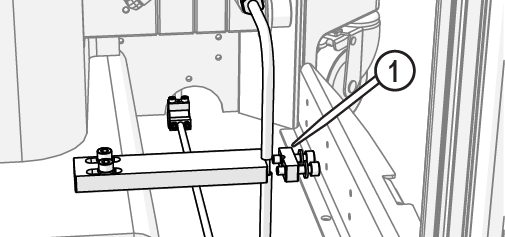

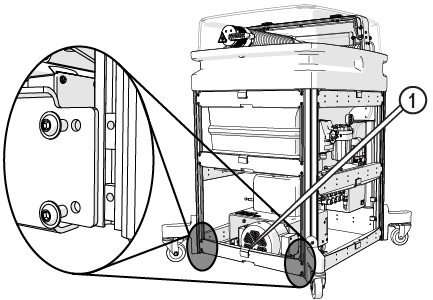

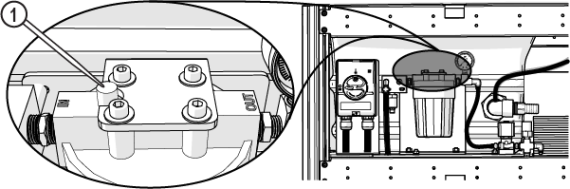

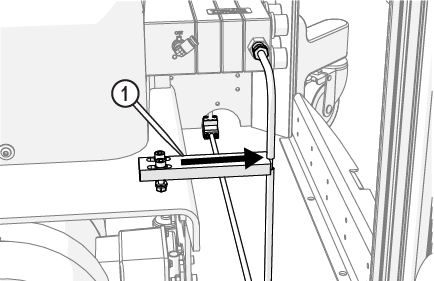

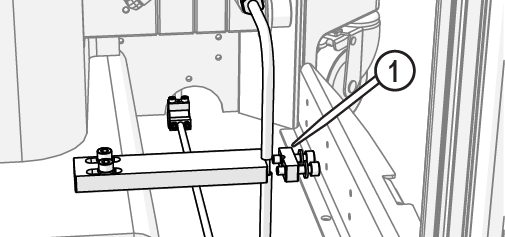

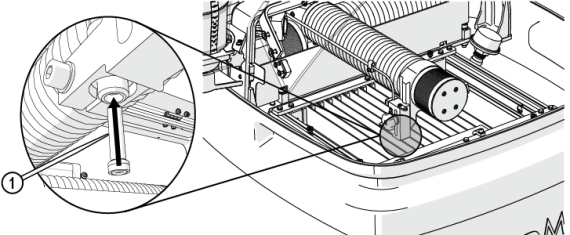

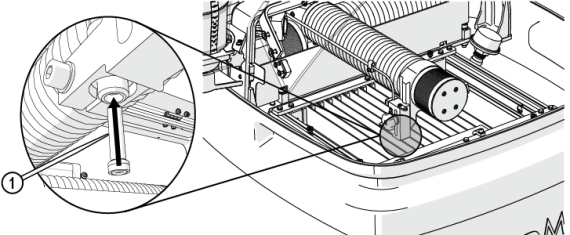

| 10. | Remove the front frame support bracket [1]. |

Figure 459

| 11. | Disconnect the pump power cable. |

Figure 460

| 12. | Disconnect the high-pressure plumbing. |

Protect the connecting ends from external contamination or debris. Debris can enter into the high-pressure plumbing system and damage the pump or nozzle.

Figure 461

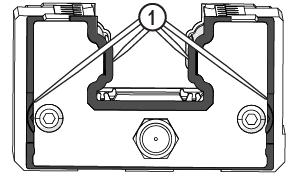

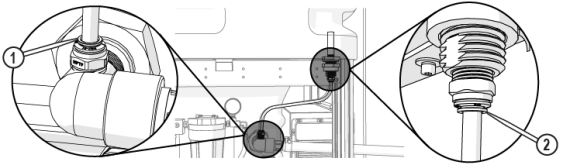

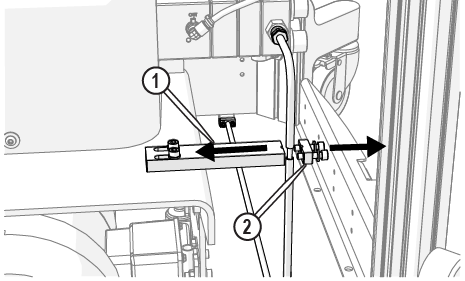

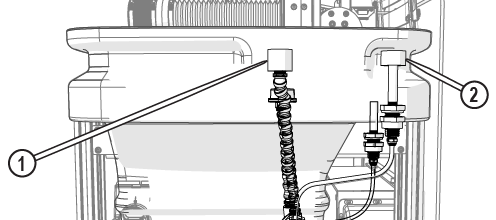

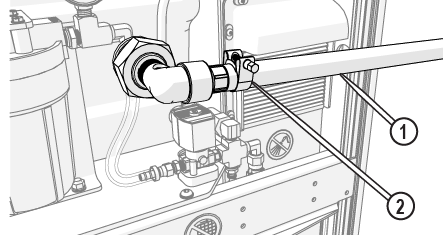

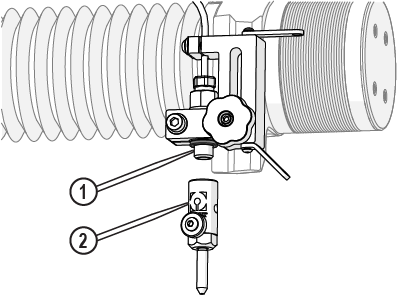

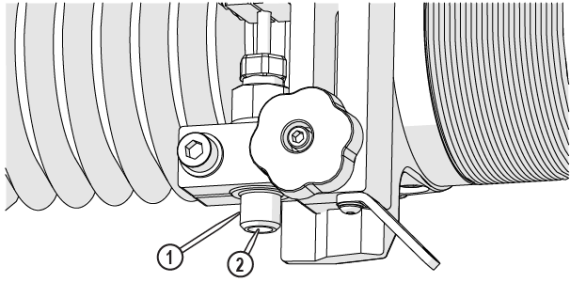

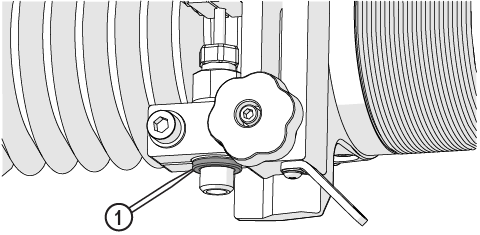

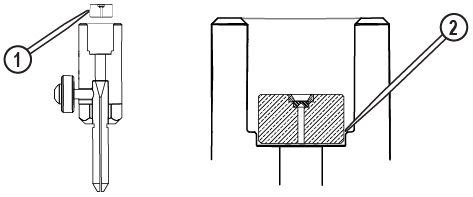

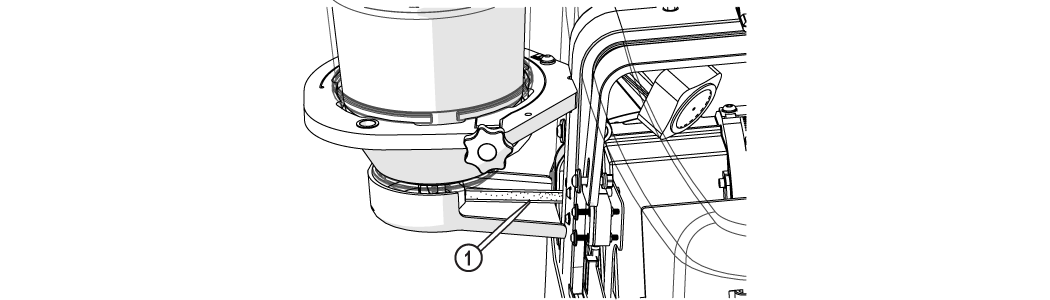

| 13. | Loosen the high-pressure support bracket [1] and remove the support cap [2]. |

Figure 462

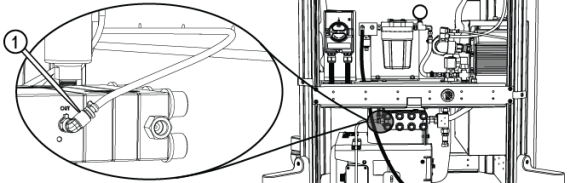

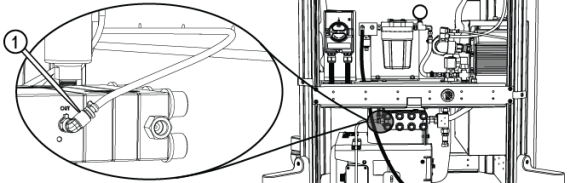

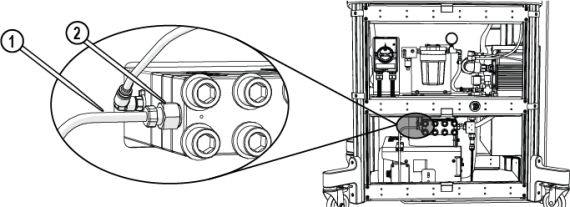

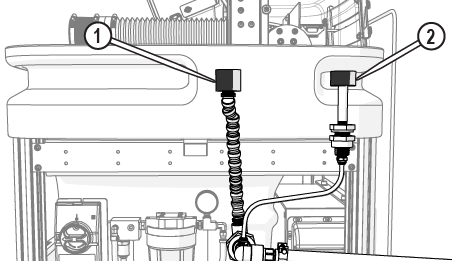

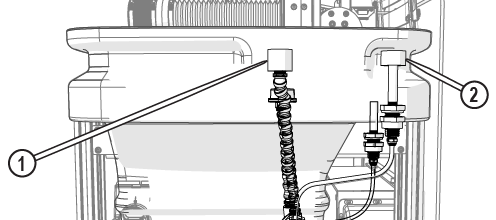

| 14. | Disconnect the cooling line OUT [1]. |

Protect the connecting ends from external contamination or debris. Debris can enter into the high-pressure plumbing system and damage the pump or nozzle.

Figure 463

| 15. | Disconnect the cooling line IN [1]. |

Protect the connecting ends from external contamination or debris. Debris can enter into the high-pressure plumbing system and damage the pump or nozzle.

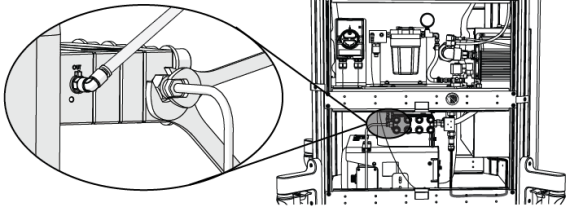

| 16. | Disconnect the incoming water hose [1]. |

Protect the connecting ends from external contamination or debris. Debris can enter into the high-pressure plumbing system and damage the pump or nozzle.

Figure 465

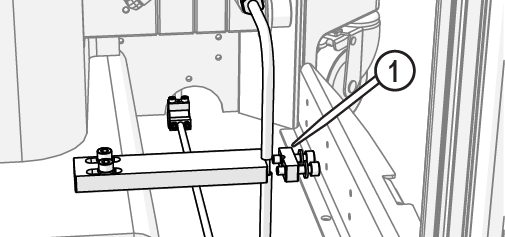

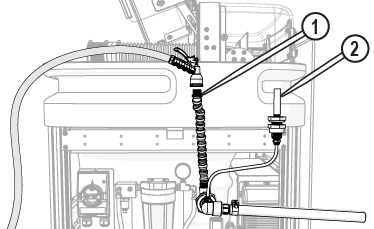

| 17. | Disconnect the transducer cable [1]. |

Protect the connecting ends from external contamination or debris. Debris can enter into the high-pressure plumbing system and damage the pump or nozzle.

Figure 466

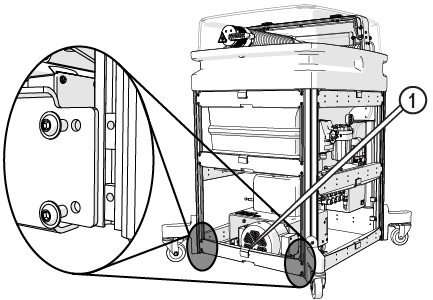

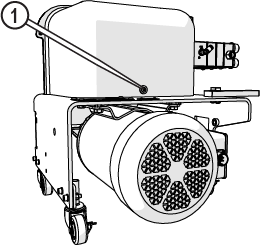

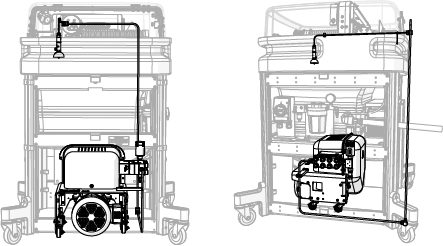

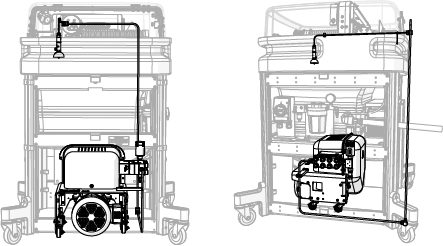

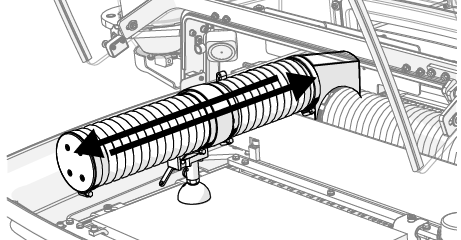

| 18. | Unlock the pump wheels and move the pump out from the machine. |

Change the Crankcase Oil

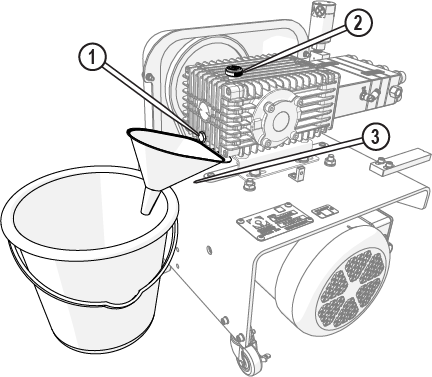

Change the crankcase oil according to the intervals specified in the Maintenance Schedule to avoid excessive wear and damage to the crankcase bearings. The oil must also be changed anytime it becomes contaminated with water or other debris.

Recommended oil:

- Type: SAE 30 non-detergent (ISO 100)

- Amount: 40.6 ounces (1.2 liters)

- Operating condition: All operating temperatures

Using other types of oil can shorten pump life and void the warranty.

| 1. | Disconnect the pump, see the Prepare the Pump for Maintenance section. |

| 2. | Remove the pump cover. |

| a. | Remove the front screw [1] and set aside. |

Figure 467

| b. | Loosen the captive screws [1] and remove the front crankcase cover. |

Figure 468

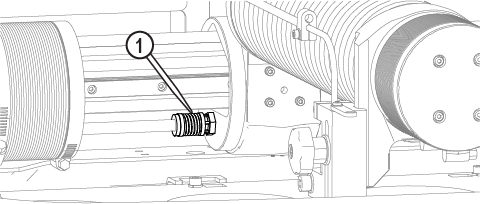

| 3. | Place a rag between the pump crankcase drain plug (Figure 469) and the frame [3] to catch oil drips. |

Crankcase oil can be hot. Be careful when removing the plug to prevent hot oil from flowing out and burning hands or fingers.

| 4. | Place a funnel and bucket below the crankcase drain plug (Figure 469). |

| 5. | Loosen or remove the oil filler port cap [2] (Figure 469). |

| 7. | Allow the oil to drain completely. |

Always dispose of used oil according to local environmental regulations.

| 8. | Replace the crankcase oil drain plug. |

| 9. | Fill with the correct amount of oil through the oil filler port. |

| 10. | Replace the oil filler port cap [2] (Figure 469). |

| 11. | Check the oil level, do one of the following. |

| • | Remove the dipstick [1] and make sure the oil level is at the full mark. |

| • | Make sure the oil level is at the top of the sight glass [2]. |

Figure 470

| 12. | Wipe any spilled oil from the crankcase and frame. |

| 13. | Replace the pump cover. |

| 14. | Reconnect the pump, see Place and Connect the Pump. |

| 15. | Reconnect the high-pressure plumbing, see Connect the High-Pressure Plumbing. |

| 16. | Reset the pump, see Reset the Pump. |

| 17. | Replace the side panels, see Install the Side Panels. |

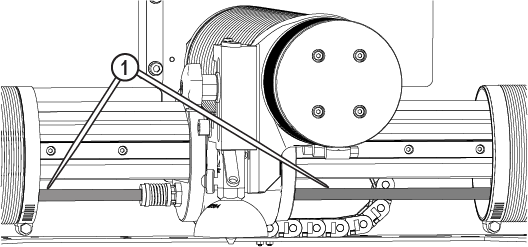

Inspect the Pump Wet End

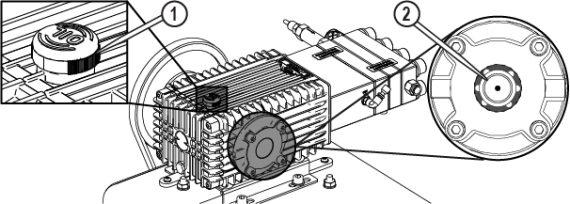

Inspect the pump between the crankcase [1] and the adapter block [2] for evidence of leaks. See the Maintenance Schedule for the recommended frequency for this task. If a leak is found, contact technical support.

Figure 471

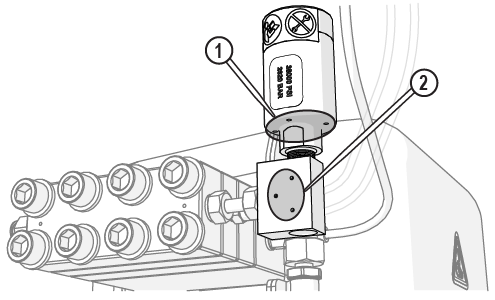

Correct Safety Valve Water Leaks

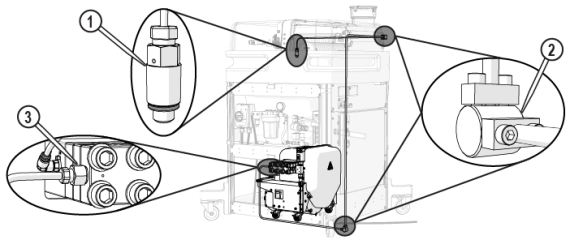

The following identifies the source of possible water leaks in the safety valve and how to correct them.

Figure 472

| Leak | Leak Description | Suspected Cause | Recommended Action |

|---|---|---|---|

| [1] | Leak from safety valve body weep holes | Seat to ceramic ball failure | Replace the Safety Valve |

| [2] | Leak from T-fitting weep holes | Seat failure | Replace the Safety Valve |

Replace the Safety Valve

Never attempt to adjust the safety valve; doing so creates a safety hazard and voids the warranty!

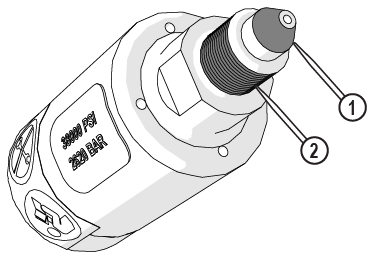

The safety valve functions to prevent excessive build-up of water pressure in the high-pressure plumbing system. During normal operation, the pump can reach extremely high pressures. When excessive-high pressures are detected, the variable frequency drive (VFD) slowly lowers the motor’s revolutions per minute (RPM) to prevent over-pressuring the system. If lowering the RPM does not prevent an overpressure condition, the safety valve activates when the factory preset pressure is reached (approximately 38 ksi), releasing the excess pressure.

Replacing the safety valve is required when leaking occurs during normal cutting operations.

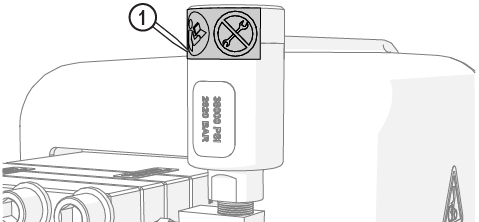

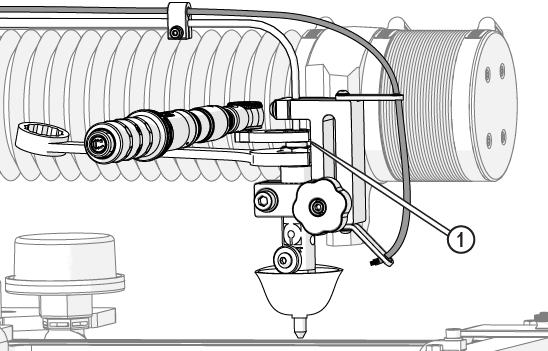

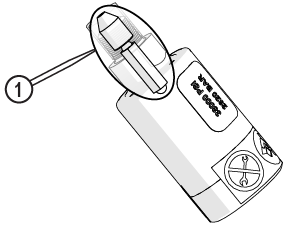

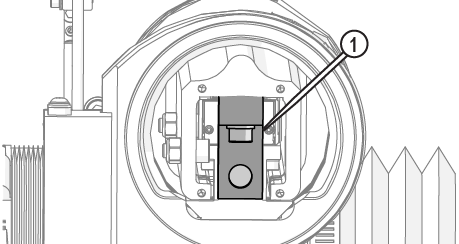

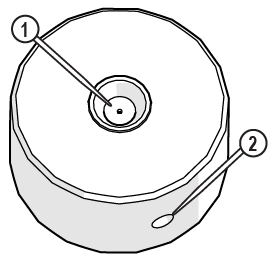

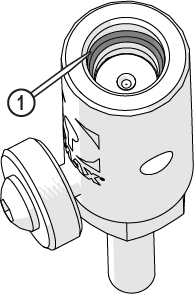

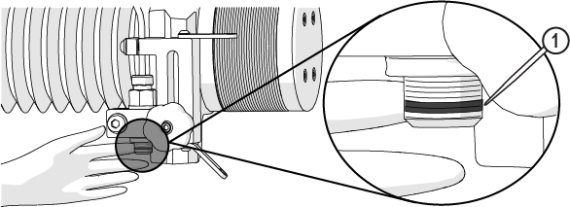

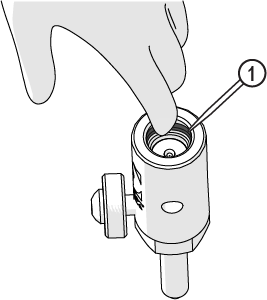

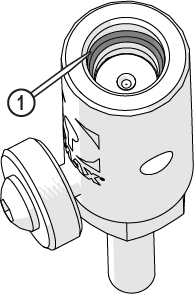

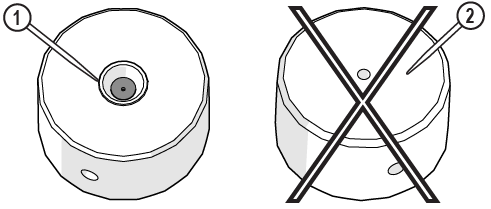

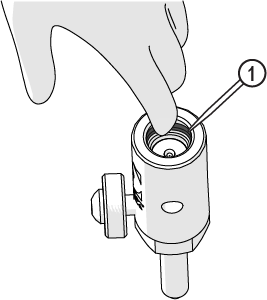

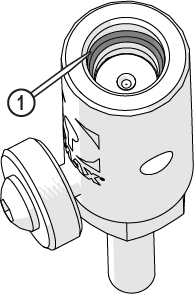

If leaking continues to occur or if the calibration seal [1] has been broken, tampered with, or damaged, replacement of the safety valve assembly is required.

Figure 473

| 1. | Turn OFF the machine. |

Figure 474

| 2. | Remove the front and right side panels. |

| 3. | Disconnect the pump power cable. |

Figure 475

| 4. | Ensure there is no pressurized water in the high-pressure lines. |

| a. | Open the lid and lock it in the upright position. |

Use care when opening or closing the lid to avoid injury. Never let the lid free-fall. Keep hand, fingers, or body parts away from the side of the table when closing the lid.

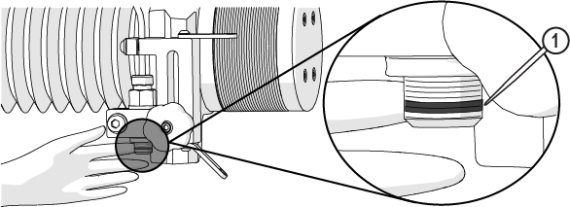

| b. | Loosen the gland nut [1] to release the pressure; water can leak from the inlet body weep hole. |

Figure 476

| c. | Tighten the gland nut [1]. |

Figure 477

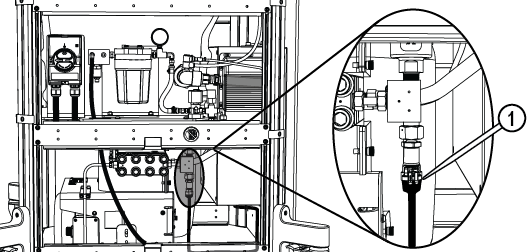

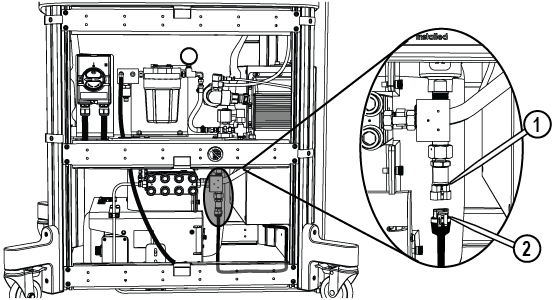

| 5. | Disconnect the transducer cable [1]. |

Protect the connecting ends from external contamination or debris. Debris can enter into the high-pressure plumbing system and damage the pump or nozzle.

Figure 478

| 6. | Loosen the T-fitting gland nut. |

Figure 479

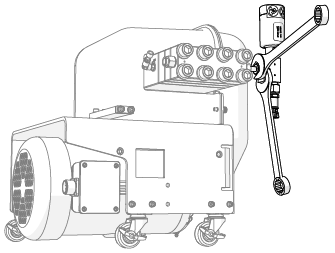

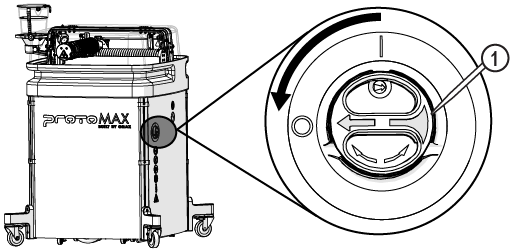

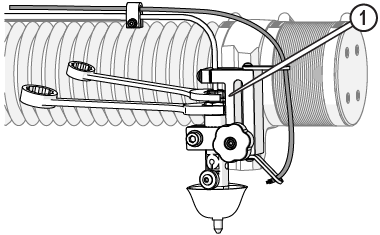

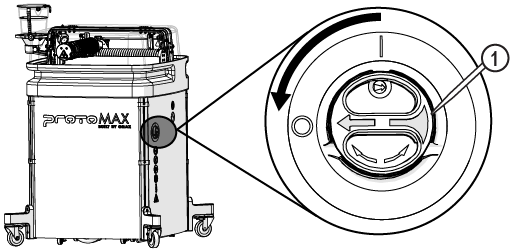

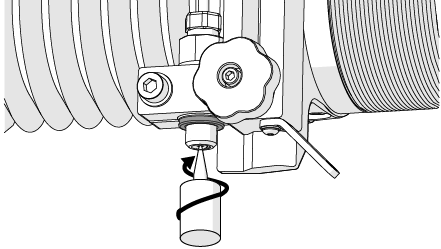

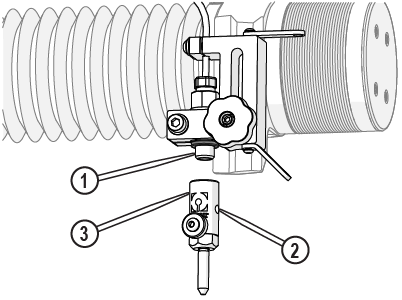

| 7. | Rotate the safety valve assembly counterclockwise until it contacts the water hose and can rotate no more. |

Safety valve internal components are loose and can fall out if the safety valve is removed while positioned vertically. Rotating the safety valve assembly to a more horizontal position before removal makes it more difficult for internal components to fall out on their own.

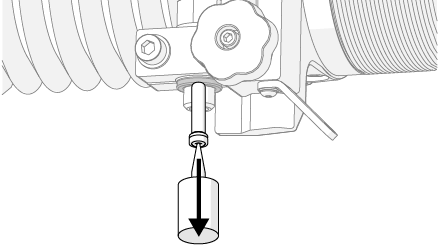

| 8. | Remove the safety valve [1]. |

Figure 480

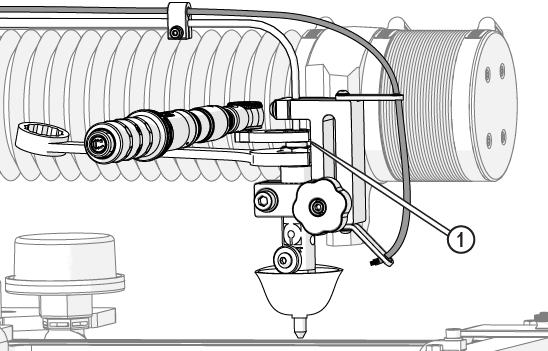

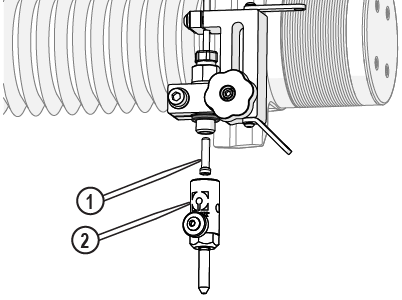

| 9. | Carefully remove the protective cap from the new safety valve. |

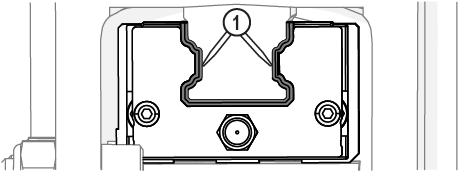

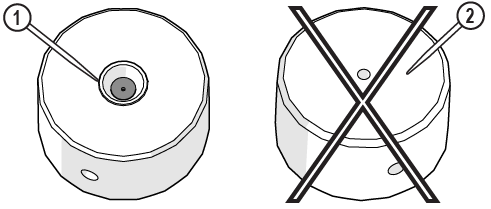

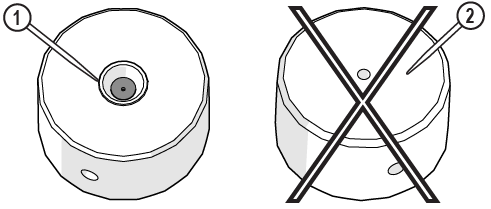

The protective cap keeps debris from contaminating the safety valve interior and keeps the internal components [1] from falling out. Always hold the safety valve with the stem up when removing the protective cap to keep the internal components from falling out and becoming contaminated with debris.

Figure 481

Avoid areas where Blue Goop can enter into the high-pressure water system (the tip of the safety valve body and the tip of the seat). Do not apply excessive amounts of Blue Goop onto the threads or seat of the safety valve. Excess Blue Goop can enter into the high-pressure water system and cause damage.

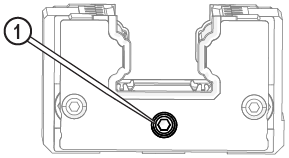

| 10. | Apply a very light coat of Blue Goop onto the coned end of the seat [1] and the threads [2] of the safety valve, if not already applied. |

Figure 482

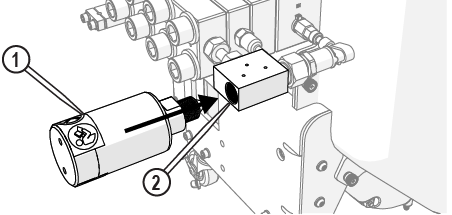

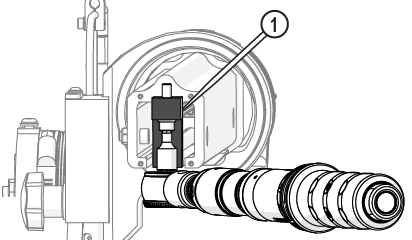

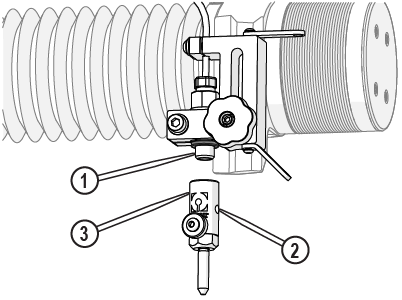

| 11. | Install the safety valve [1] onto the T-fitting [2] then hand-tighten. |

Figure 483

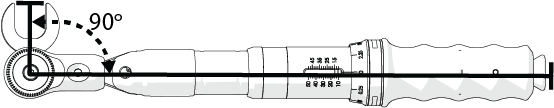

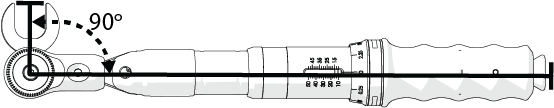

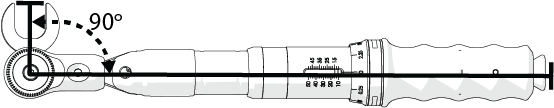

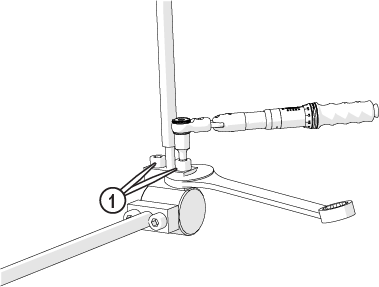

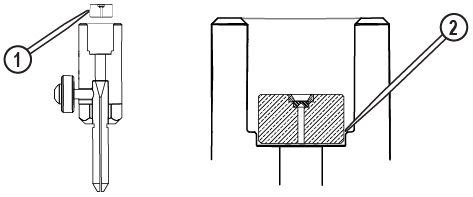

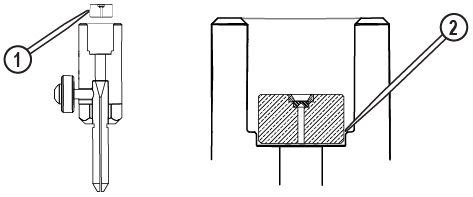

The jaws of the crowfoot must maintain a 90-degree angle to the horizontal axis of the torque-wrench handle throughout the torquing rotation. Other angles of orientation can alter the set torque.

Figure 484

| 12. | Torque the safety valve [1]. |

Figure 485

| 13. | Rotate the safety valve so that it is perpendicular to the floor. |

| 14. | Torque the T-fitting gland nut. |

Figure 486

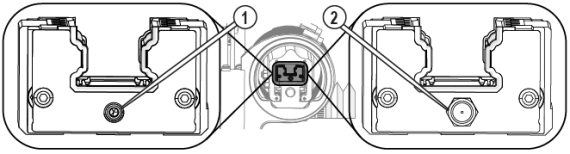

| 15. | Apply a heavy coat of dielectric compound to the transducer cable [2], then connect the transducer cable to the transducer [1]. |

Figure 487

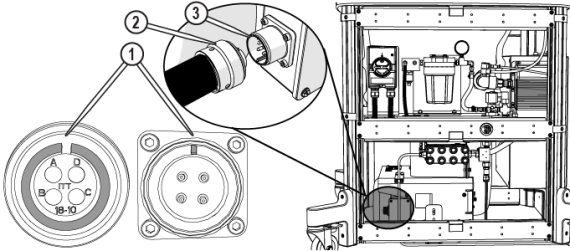

| 16. | Apply a heavy coat of dielectric compound to the power cord plug [2] (Figure 488). |

| 17. | Aline the notches [1] on the power cord plug and power connector [3], then push until the power cord plug seats in the power connector (Figure 488). |

| 18. | Rotate the shell counterclockwise until the threads engage, then turn the shell clockwise to tighten. |

| 19. | Flush the high-pressure plumbing, see Flush the High-Pressure Plumbing. |

| 20. | Reset the pump, see Reset the Pump. |

| 21. | Install the nozzle, if removed, see Install the Nozzle, perform a nozzle test, and see Test the Nozzle. |

| 22. | With the pump running at high pressure, carefully inspect the safety valve for signs of water leakage. Correct all leakage problems before continuing. |

| 23. | Replace the side panels, see Install the Side Panels. |

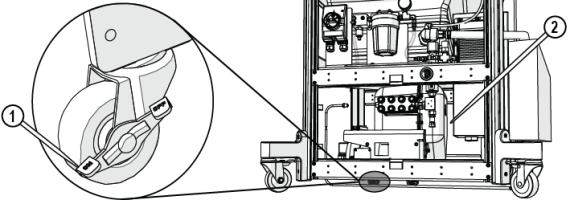

Place and Connect the Pump

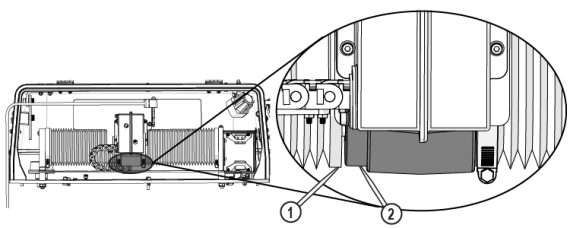

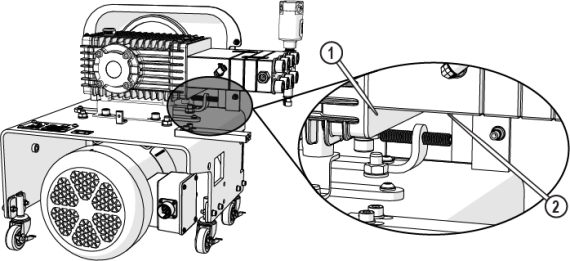

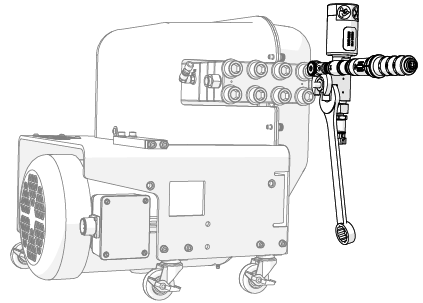

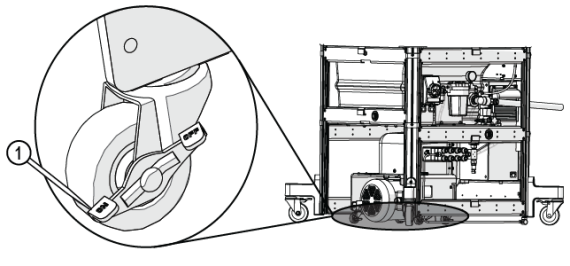

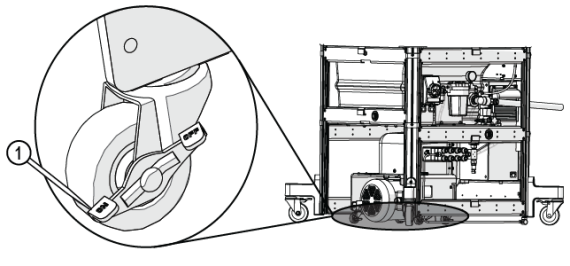

| 1. | Roll the pump under the table, leaving a 1–2 in. space [2] between the back of the pump and the control cabinet, then lock one of the pump wheels [1]. |

Figure 489

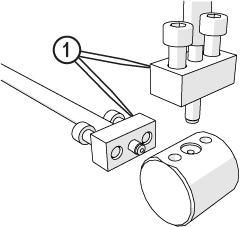

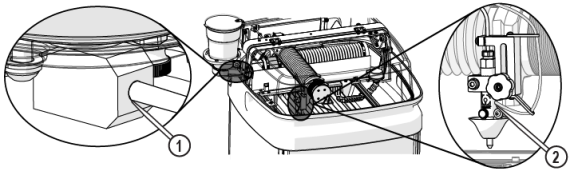

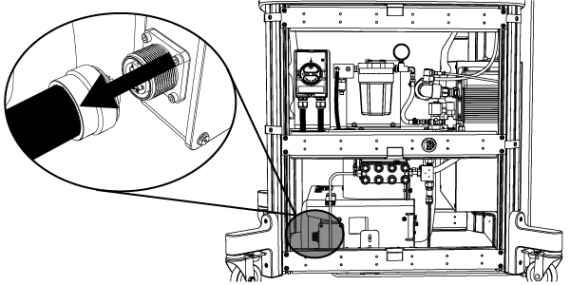

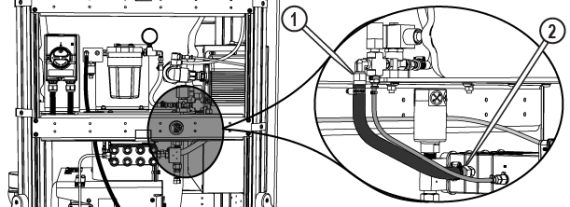

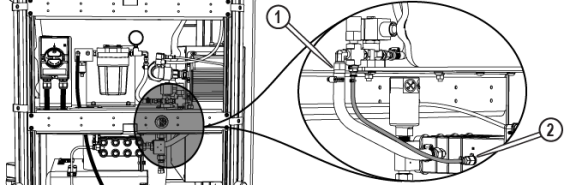

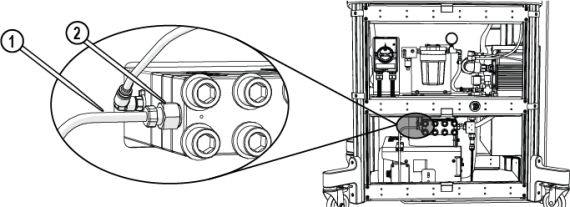

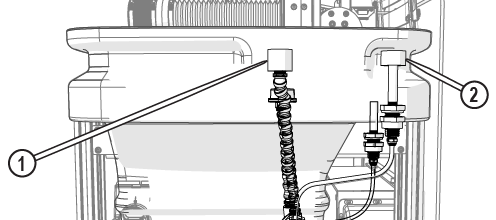

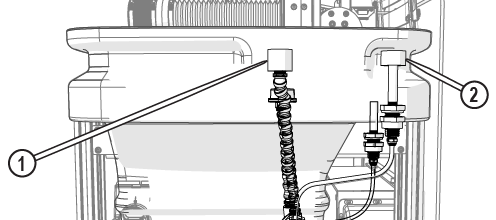

| 2. | Connect the cooling line OUT to the push-to-connect OUT connection [1] on the pump. The cooling OUT line and connections have yellow cable ties attached. |

Figure 490

| 3. | Connect the cooling line from the IN connection [2] on the pump to the push-to-connect fitting [1]. The cooling IN line and connections have red cable ties attached. |

Figure 491

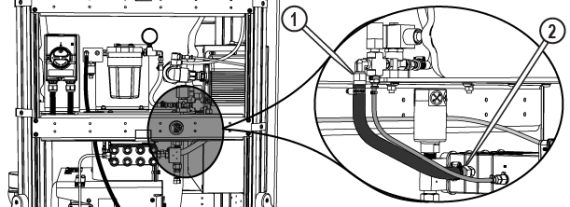

Do not use teflon tape or pipe sealant on the water connections. Teflon thread or sealant particles can enter into the high-pressure plumbing system and damage the pump and nozzle.

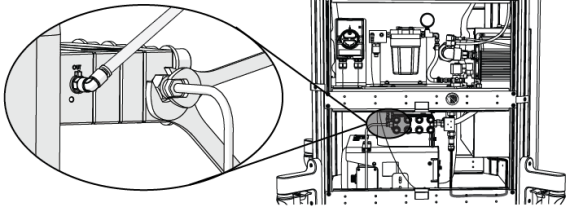

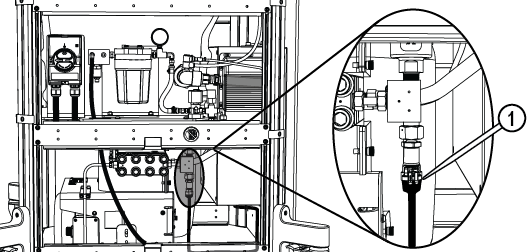

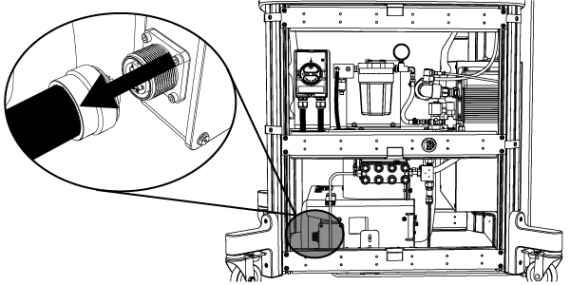

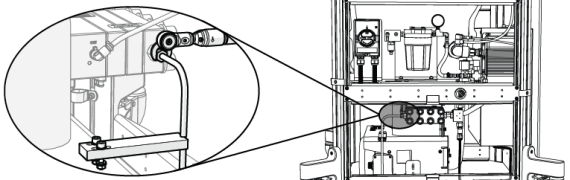

| 4. | Connect the supply water hose from the pump wet end [2] to the 90-degree fitting [1] and tighten. |

Figure 492

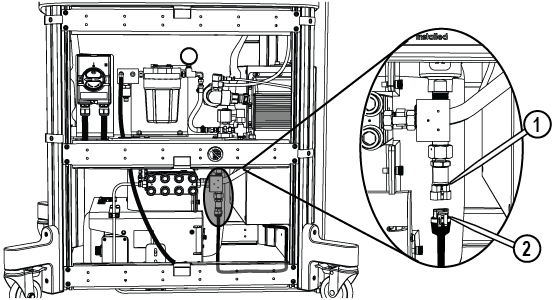

| 5. | Apply a heavy coat of dielectric compound to the transducer cable [2], then connect the transducer cable to the transducer [1]. |

Figure 493

| 6. | Apply a heavy coat of dielectric compound to the power cord plug [2] (Figure 488). |

| 7. | Aline the notches [1] on the power cord plug and power connector [3], then push until the power cord plug seats in the power connector (Figure 488). |

| 8. | Rotate the shell counterclockwise until the threads engage, then turn the shell clockwise to tighten. |

Connect the High-Pressure Plumbing

When preparing the ProtoMAX high-pressure tubing, it is critical to follow instructions. Some high-pressure tubing and fittings are pre-assembled. Fittings may need readjustment during installation to make sure proper seals and eliminate potential leaks. Use the provided Stand-off tool to make sure the fittings are correctly seated and sealed.

| 1. | Verify the u-shape high-pressure nipple, gland nut, slotted collet, and collar are assembled and aligned. See High-Pressure Gland Nut Assembly. |

High-pressure nipples have left-hand threads, therefore when connecting components, turn clockwise to loosen and counterclockwise tighten. Cross threading high-pressure connections can cause leaks or water damage from the leak(s).

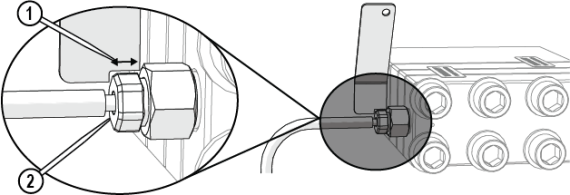

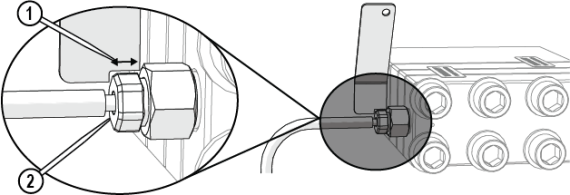

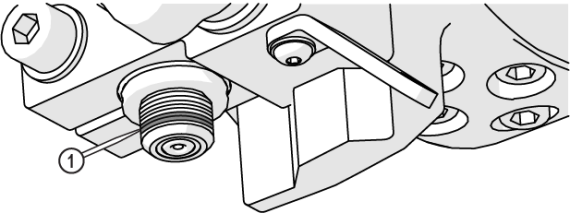

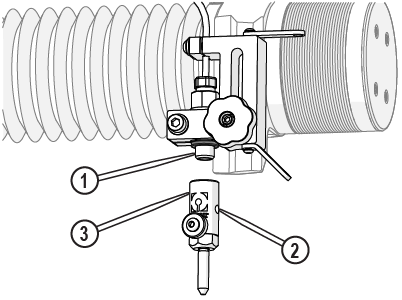

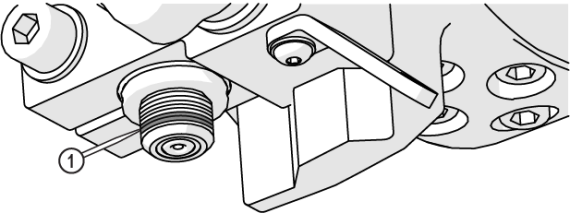

| 2. | Verify the collar [1] is installed in the correct position using the stand-off tool [2], then adjust the collar to the correct depth if needed. |

Figure 495

| 3. | Position the pump so that the high-pressure plumbing is aligned vertically and horizontally, and the rear of the pump is 1–2 in. from the control cabinet. |

Figure 496

| 4. | Attach the assembled u-shape nipple [1] to the pump high-pressure outlet OUT connection [2] and hand-tighten. |

Figure 497

| 5. | Verify the gland nut [2] is set approximately to the depth of the nozzle stand-off tool [1]. |

Figure 498

| 6. | Adjust the position of the bracket [1], then tighten the bracket. |

Figure 499

| 7. | Lock the pump wheels [1]. |

Figure 500

| 8. | Torque the pump connection (Figure 502). |

The jaws of the crowfoot must maintain a 90-degree angle to the horizontal axis of the torque-wrench handle throughout the torquing rotation. Other angles of orientation can alter the set torque.

Figure 501

| 9. | Attach the bracket cap [1] and tighten. |

Move the conduit out of the way so that it is not trapped under the bracket.

Figure 503

| 10. | Reinstall the front support bracket [1] with the provided hardware. |

Figure 504

Reset the Pump

The reset pump test runs a 30-second sequence to reset the pump. Do this test:

- Before operating the ProtoMAX for the first time

- After changing the nozzle orifice

- Repairing or replacing the pump

- Repairing high-pressure plumbing leaks

- When required by a fault or alert message

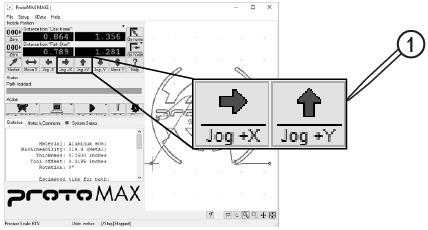

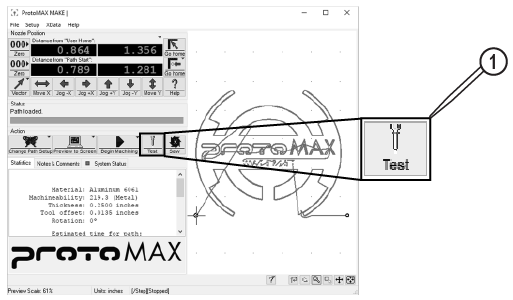

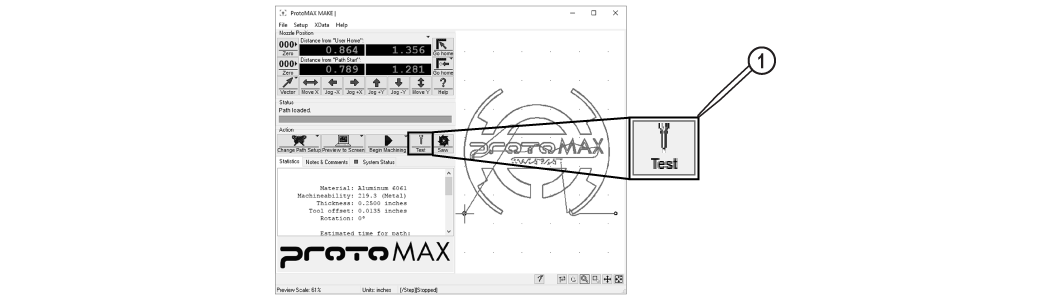

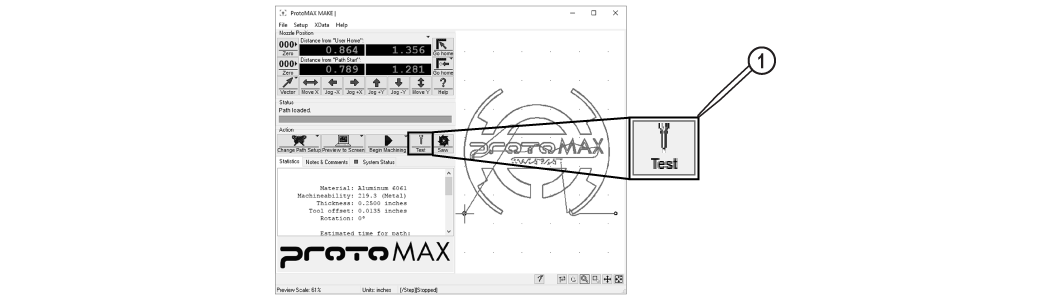

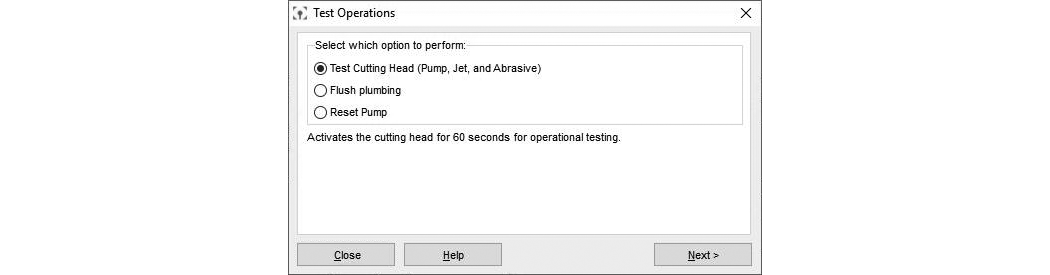

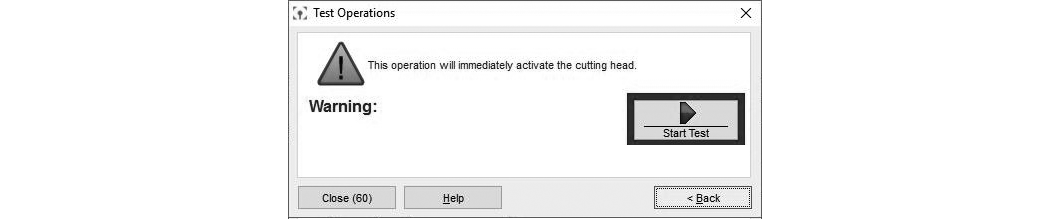

| 1. | Open MAKE. |

| 2. | Move the nozzle between two slats. |

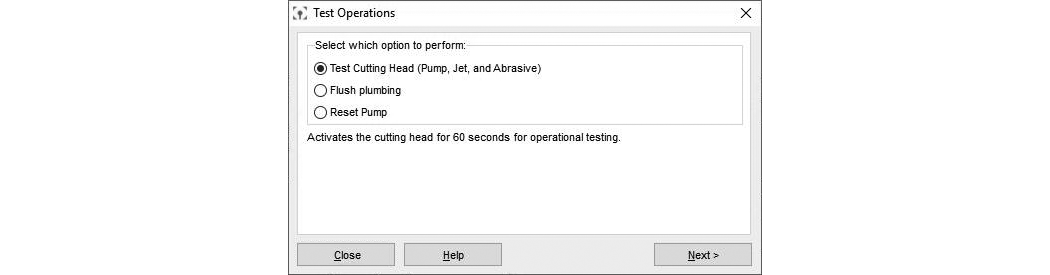

| 3. | Click Test. |

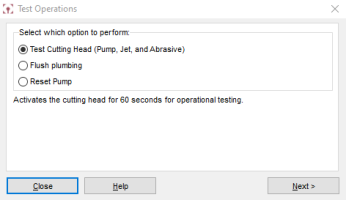

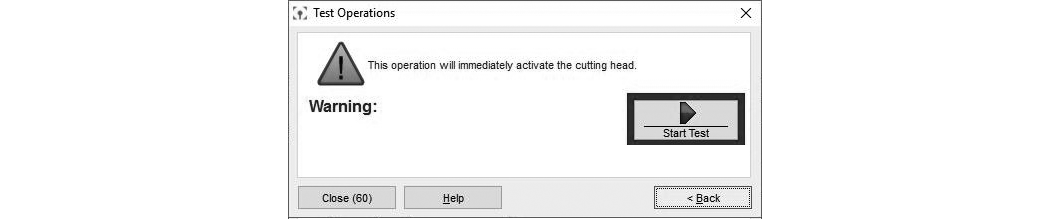

| 4. | In Test Operations, select Reset Pump, and click Next. |

| 5. | Click Start Test and check the high-pressure plumbing for leaks (the dialog box closes when the test is complete). |

Table Maintenance

This section contains procedures for performing the recommended table maintenance. See the Maintenance Schedule for the recommended frequency for this task.

Always wear safety glasses when performing maintenance on the machine.

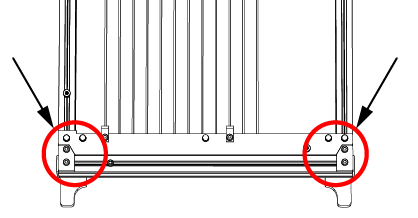

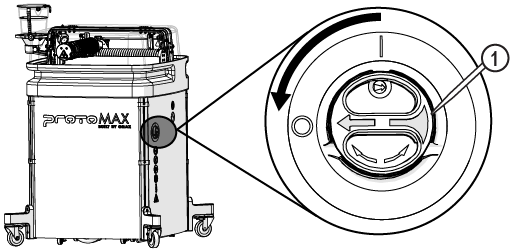

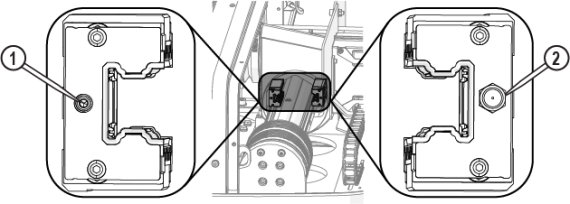

Change the Electrical Control Enclosure Air Filters

The air filters make sure debris and other pollutants do not enter the electrical enclosure. Regular air filter changes reduce wear and damage to enclosure control electronics. See the Maintenance Schedule for the recommended frequency for this task.

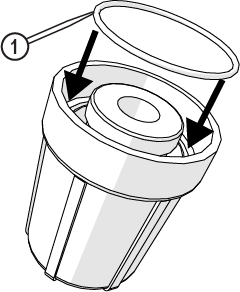

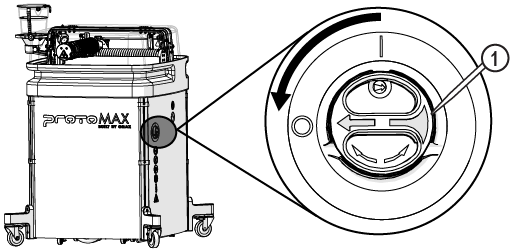

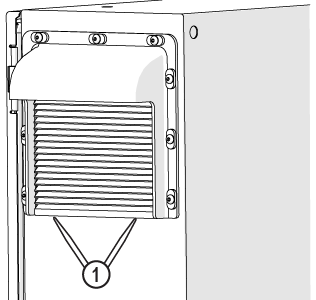

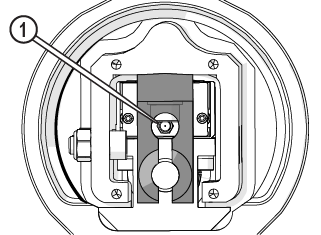

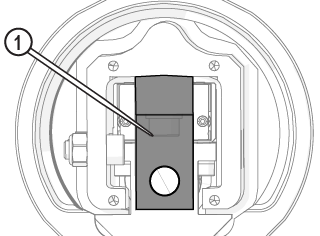

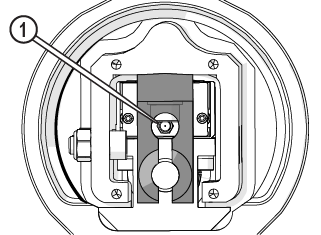

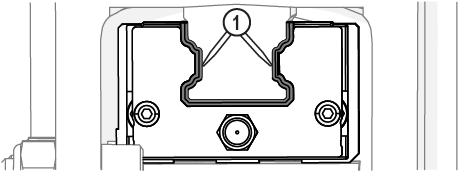

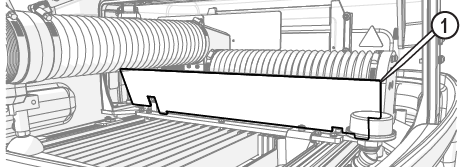

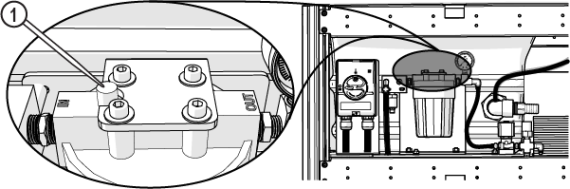

| 1. | Press up on the tabs located under the bottom edge [1] of the filter cover and lift the cover using both hands to unhinge it from the frame. |

Figure 505

| 2. | Tilt and lift the filter cover out from the electrical control enclosure. |

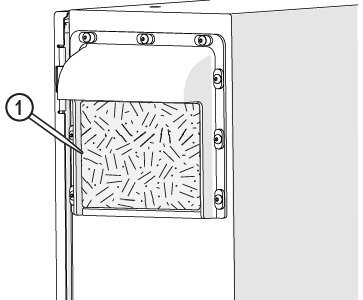

| 3. | Remove and discard the old filter [1]. |

Figure 506

| 4. | Wipe any debris from the filter cover surfaces. |

| 5. | Press the new filter into the receptacle. |

| 6. | Reinstall the filter cover. |

| 7. | Repeat the steps to change the filter on the other side of the machine. |

Change the Water Filter Cartridge and Inspect O-ring

The water filter removes debris from the incoming water. See the Maintenance Schedule for the recommended frequency for this task.

| 1. | Turn OFF the machine. |

Figure 507

| 2. | Disconnect the power cord from the electrical outlet. |

| 3. | Turn OFF the water supply. |

| 4. | Ensure there is no pressurized water in the high-pressure lines. |

| a. | Open the lid and lock it in the upright position. |

Use care when opening or closing the lid to avoid injury. Never let the lid free-fall. Keep hand, fingers, or body parts away from the side of the table when closing the lid.

| b. | Loosen the gland nut [1] to release the pressure; water can leak from the inlet body weep hole. |

Figure 508

| c. | Tighten the gland nut [1]. |

Figure 509

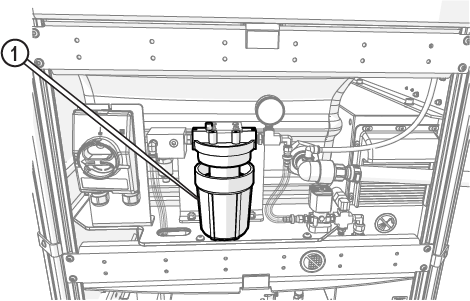

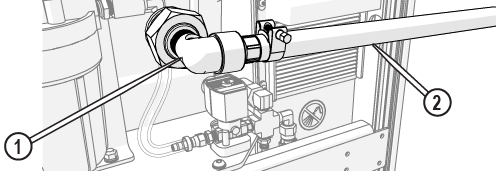

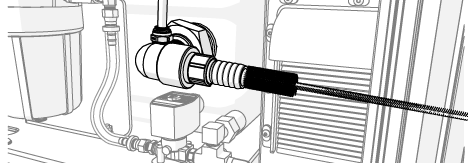

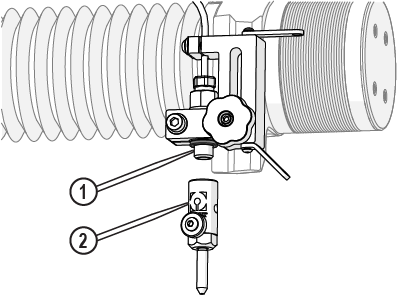

| 5. | Remove the water filter housing [1]. |

Figure 510

| 6. | Remove and discard the filter element. |

| 7. | Wash and rinse the filter housing to remove all sediment and coatings from inside the filter housing. |

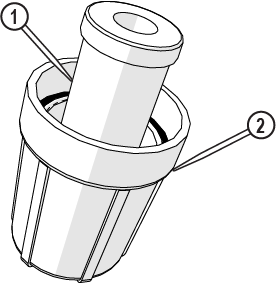

| 8. | Inspect the filter housing O-ring [1] for damage and replace it if needed (Figure 511). |

| 9. | Apply a light coat of silicone to the filter housing O-ring [1], then insert it into the water filter housing. |

To prevent leaking, do not twist or bind the O-ring.

| 10. | Place the new filter element [1] into the filter housing [2]. |

The filter element is bi-directional and can be installed in either direction.

Figure 512

| 11. | Install the lower filter housing assembly to the upper filter housing and hand-tighten. |

Do not tighten the filter housing with the water filter wrench. Damage to the filter housing or filter housing O-ring can occur and can cause leaks.

| 12. | Turn ON the water supply. |

| 13. | Place a rag over the top of the filter, then hold down the air bleed button [1] to release air from the filter. |

If all of the air is not purged from the filter, the pump cannot develop sufficient pressure, and the pump shuts down.

Figure 513

| 14. | Reset the pump to recalibrate the pump pressure. |

| 15. | Verify the water pressure when the pump is running. |

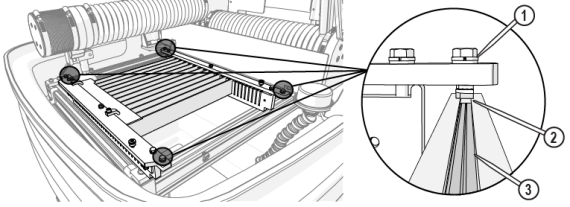

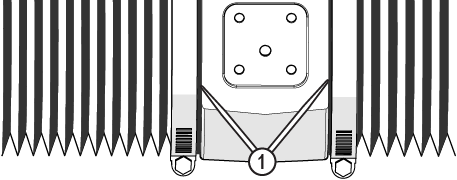

Rotate or Replace the Slats

Bacteria in the tank water can build up. A minor break in the skin can introduce harmful bacteria into a wound. Always wear protective gloves if you have cuts or open wounds on your hands. Wear gloves that protect against sharp metal edges.

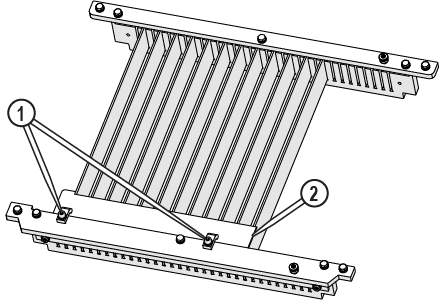

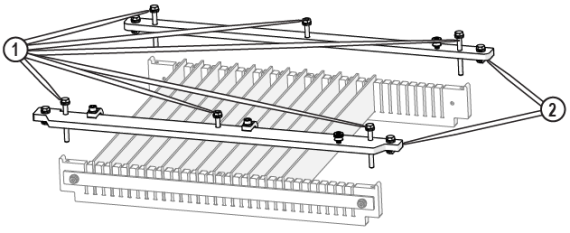

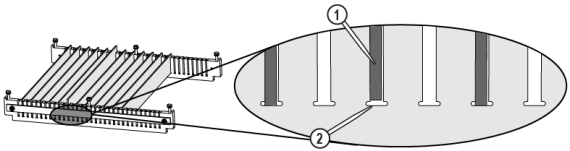

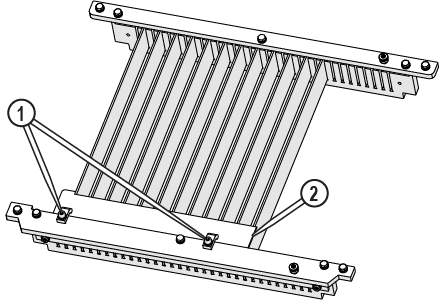

In time, table slats can become scored with deep garnet abrasive waterjet cuts and become unable to provide stability and support required for precision cutting. See the Maintenance Schedule for the recommended frequency for this task.

The working life of a slat can be significantly improved by periodically rotating them to different table locations.

When replacing a defective slat, inspect the slat comb for excessive wear and replaced them as needed. Worn slat combs allow the slats to rock back and forth, which can interfere with cutting precision.

| 1. | Open the lid and lock it in the upright position. |

Use care when opening or closing the lid to avoid injury. Never let the lid free-fall. Keep hand, fingers, or body parts away from the side of the table when closing the lid.

| 2. | Remove the garnet bins. |

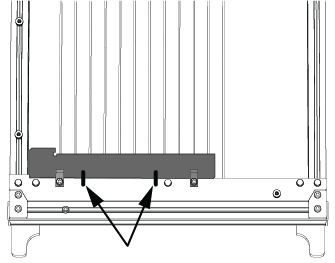

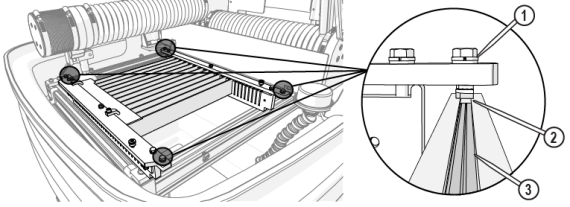

Figure 514

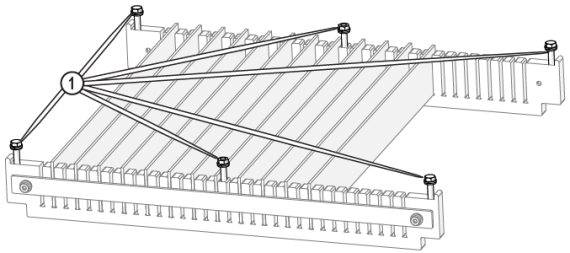

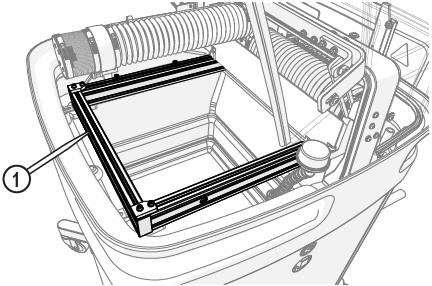

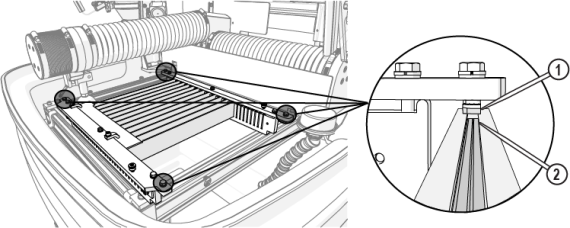

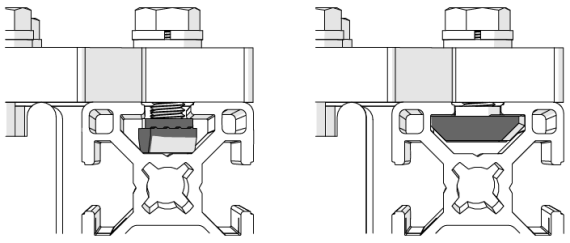

| 3. | Loosen the cutting deck bolts [1] and align the t-nuts [2] with the frame slot [3]. |

Figure 515

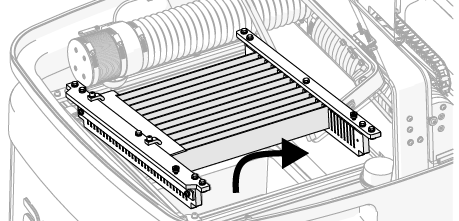

| 4. | Move the Y-axis to allow enough space to remove the cutting deck. |

Use care when removing the cutting deck to avoid damage to the Y- and Z-axes and the nozzle assembly.

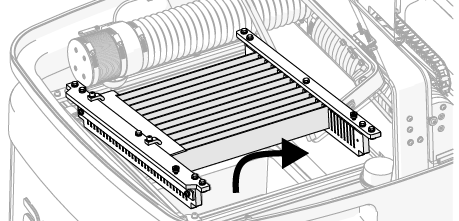

| 5. | Carefully lift the cutting deck out of the catcher tank. |

Figure 516

| 6. | Place a mark on the mounting plate of the fixturing plate location. |

If a mark is not placed on the mounting plate, a new fixturing plate needs to be cut after re-installation.

Figure 517

| 7. | Loosen the fixturing plate screws [1] and remove the fixturing square [2]. |

Figure 518

| 8. | Remove the screws [1] and the mounting plates [2]. |

Figure 519

| 9. | Reinstall the screws [1] in the slat combs and hand-tighten to prevent dirt or debris from entering the screw threads. |

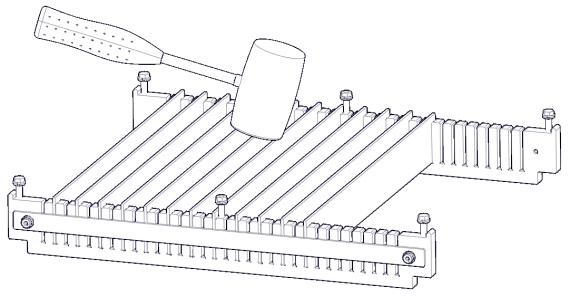

| 10. | Remove all badly worn slats. |

| 11. | Tap the slat combs and slats with a soft blow mallet to dislodge encrusted garnet, if needed. |

Figure 521

| 12. | Clean the slat combs and spray the slat assembly with a strong stream of water. |

| 13. | Rotate or replace slats as needed. |

Ensure the slat(s) [1] are seated flat against the slat comb slot [2]. Slightly raised slats can cause materials to wobble while cutting.

Figure 522

| 14. | Remove the screws and t-nuts from the mounting plate. |

| 15. | Apply a coat of anti-seize to the threads of the mounting plate screws and t-nuts. |

| 16. | Reinstall the mounting plates [2]. |

| 17. | Clean the frame t-slot [1], spray with a strong stream of water if needed. |

Figure 524

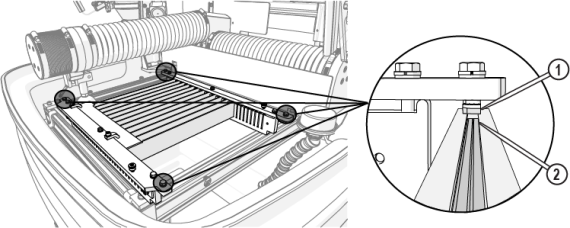

| 18. | Reinstall the cutting deck. |

Use care when installing the cutting deck to avoid damage to the Y- and Z-axes and the nozzle assembly.

| a. | Rotate the t-nuts to align with the frame slot and tighten the t-nut bolt. |

| b. | Place the cutting deck on the frame with t-nuts [1] in the frame slot [2]. |

Figure 525

| c. | Make sure that the notches in the cutting deck align with the front mounting plate brackets. |

Figure 526

| d. | Loosen the t-nuts completely, then tighten to lock in place. |

Figure 527

Figure 528

| 19. | Align the fixturing plate to the marks and tighten the screws [1] or recut the fixturing square [2]. See the Software Help files about fixturing squares. |

Figure 529

| 20. | Reinstall the garnet bins. |

Figure 530

Use care when opening or closing the lid to avoid injury. Never let the lid free-fall. Keep hand, fingers, or body parts away from the side of the table when closing the lid.

| 21. | Close the lid. |

Maintain the High-Pressure Lines and Components

Maintaining proper cone angles on the body and tube is critical in creating a high-pressure seal. The seal is created when the angled metal edges of the tube cone seat press against the metal edges inside the body cone. The body cone inside has a slightly larger angle of the high-pressure fitting. This slight difference in angles between the body and tube cones creates a tight, metal-to-metal seal between both components. See 401542, Diagram, Exploded, HP System Components, ProtoMAX for part numbers. See the Maintenance Schedule for the recommended frequency for this task.

To avoid injury or damage, always make sure there is no high-pressure water in the lines, see Prepare the High-Pressure Lines for Repair before repairing high-pressure lines or components.

Prepare the High-Pressure Lines for Repair

Before performing maintenance on the high-pressure lines, release all pressurized water.

| 1. | Turn OFF the macine [1], if needed. |

Figure 531

| 2. | Clean all high-pressure lines and components thoroughly before disassembly to remove all abrasive and debris. |

| 3. | Turn OFF the water, if needed. |

| 4. | Turn OFF the breaker power switch, if needed. |

| 5. | Make sure there is no pressurized water in the high-pressure lines. |

| a. | Open the lid and lock it in the upright position. |

Use care when opening or closing the lid to avoid injury. Never let the lid free-fall. Keep hand, fingers, or body parts away from the side of the table when closing the lid.

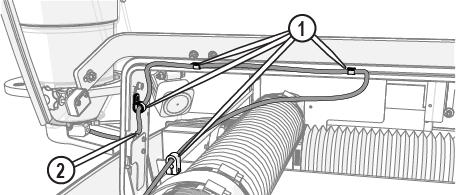

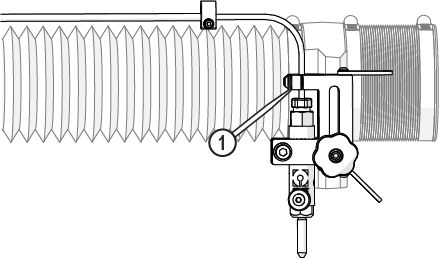

| b. | Loosen the Z-axis tubing clamp [1]. |

Figure 532

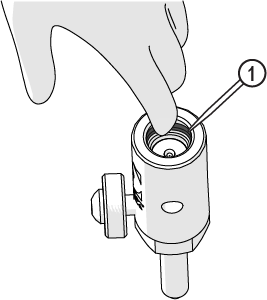

| c. | Loosen the gland nut [1] to release the pressure; water can leak from the inlet body weep hole. |

Figure 533

| d. | Tighten the gland nut [1], if needed. |

Figure 534

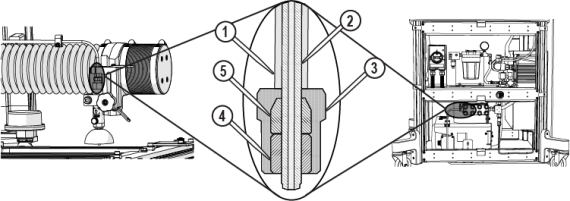

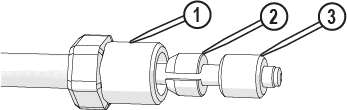

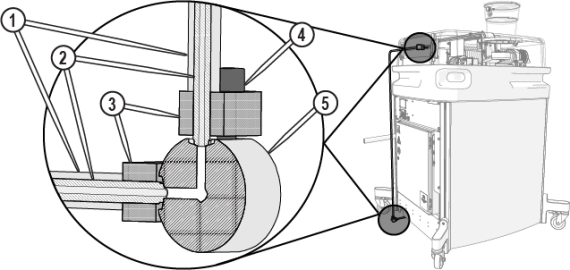

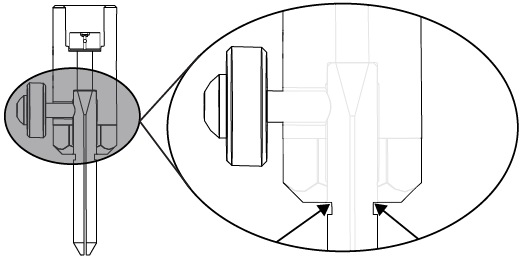

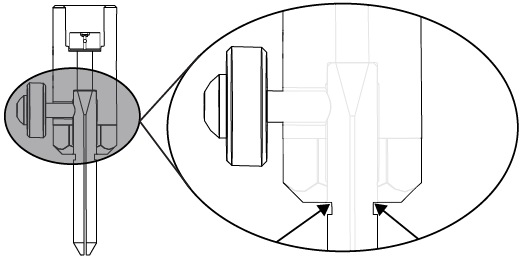

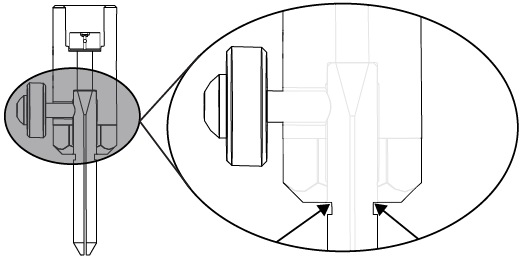

High-Pressure Gland Nut Assembly

Gland nut connections are located at the high-pressure nozzle and the pump. The high-pressure gland nuts consist of the following components.

Figure 535

| [1] Conduit | [2] High-pressure nipple | [3] Gland nut | [4] Collar | [5] Slotted collet |

Maintain the Nozzle High-Pressure Gland Nut

When preparing the ProtoMAX high-pressure tubing, it is important to follow instructions. Some high-pressure tubing and fittings are pre-assembled. Fittings may need readjustment during installation to make proper seals and eliminate potential leaks. Use the provided stand-off tool to make sure the fittings are correctly seated and sealed.

Nipples contain small caps to protect the threading and keep debris from entering the high-pressure plumbing during shipment. Remove the caps before assembling the high-pressure plumbing fittings. Do not use pliers to remove the black caps or cut the black caps from the nipple. Pliers and knives damage the nipple threads causing leaks in the high-pressure lines and water damage.

| 1. | Release any pressurized water from the high-pressure lines, see Prepare the High-Pressure Lines for Repair. |

| 2. | Raise the Z-axis approximately 1 in. (3 cm). |

| 3. | Completely loosen the gland nut [1] from the inlet body. |

Figure 536

| 4. | If replacing the high-pressure line, loosen and remove the high-pressure fitting that is on the end of the high-pressure line that extends out from the back of the machine. See Maintain the High-pressure Fittings for removal instructions. |

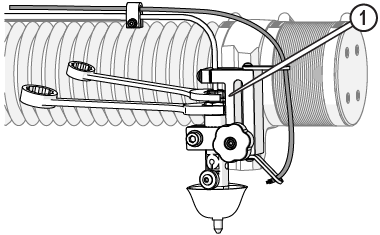

| 5. | Loosen or remove the Z-axis tubing clamp [1]. |

Figure 537

| 6. | Replace the damaged component. |

If replacing the high-pressure nipple, remove the tubing clamp [1] and disassemble the fitting at the rear of the cutting deck, see Maintain the High-Pressure Fittings, remove the old nipple from the conduit, then insert the new nipple in the conduit and reattach the tubing clamp.

Figure 538

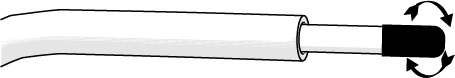

| 7. | Rotate the nipple cap clockwise to remove it and make sure that there is no debris in the high-pressure tube, if needed. |

Figure 539

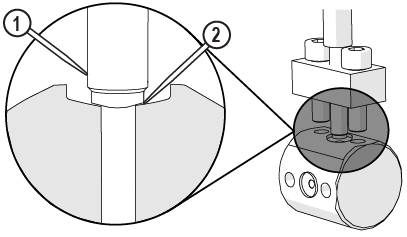

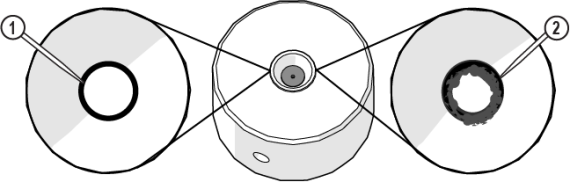

| 9. | Place the slotted collet [2] on the nipple with the tapered end facing the gland nut [1] (Figure 540). |

| 10. | Thread the collar [3] on to the nipple (Figure 540). |

| 11. | Use the stand-off tool [1] to set the collar depth. |

High-pressure nipples have left-hand threads, therefore when connecting components, turn clockwise to loosen and counterclockwise tighten. Cross threading high-pressure connections can cause leaks and water damage from the leak(s).

| 12. | Support the high-pressure tube [1], so the nipple is perpendicular [2] to the inlet body [3], then attach the gland nut to the inlet body and hand-tighten (Figure 540) |

Figure 542

| 13. | Torque the gland nut [1]. |

Figure 543

| 14. | Attach the z-axis tubing clamp [1]. |

Figure 544

| 15. | Install and tighten the nipple tubing clamp [1]. |

Figure 545

| 16. | Flush the high-pressure plumbing, see Flush the High-Pressure Plumbing. |

| 17. | Reset the pump, see Reset the Pump. |

| 18. | Install the nozzle, if removed, see Install the Nozzle, perform a nozzle test, and see Test the Nozzle. |

Maintain the Pump High-Pressure Gland Nut

When preparing the ProtoMAX high-pressure tubing, it is important to follow instructions. Some high-pressure tubing and fittings are pre-assembled. Fittings may need readjustment during installation to make proper seals and eliminate potential leaks. Use the provided stand-off tool to make sure the fittings are correctly seated and sealed.

Nipples contain small caps to protect the threading and keep debris from entering the high-pressure plumbing during shipment. Remove the caps before assembling the high-pressure plumbing fittings. Do not use pliers to remove the black caps or cut the black caps from the nipple. Pliers and knives damage the nipple threads causing leaks in the high-pressure lines and water damage.

| 1. | Thoroughly clean all high-pressure components before disassembly. |

| 2. | Release any pressurized water from the high-pressure lines, see Prepare High-Pressure Lines for Repair. |

| 3. | Loosen the gland nut. |

Figure 546

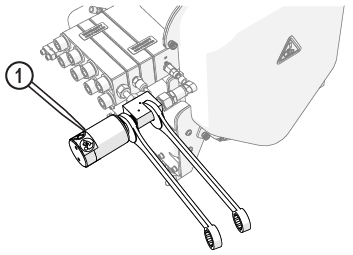

| 4. | Remove the bracket cap [1]. |

Figure 547

| 5. | Replace the damaged component. |

If replacing the high-pressure nipple, disassemble the fitting at the rear of the machine, see Maintain the High-Pressure Fittings, then remove the old nipple from the conduit, then insert the new nipple in the conduit.

| 6. | Rotate the nipple cap clockwise to remove it and verify there is no debris in the high-pressure tube. |

Figure 548

| 7. | Place the gland nut [1] on the nipple. |

Figure 549

| 8. | Place the slotted collet [2] on the nipple with the tapered end facing the gland nut [1] and thread the collar [3] on the nipple (Figure 95). |

| 9. | Use the stand-off tool [1] to verify the collar depth. |

High-pressure nipples have left-hand threads, therefore when connecting components, turn clockwise to loosen and counterclockwise to tighten. Cross threading high-pressure connections cause leaks and water damage from the leak(s).

Figure 550

| 10. | Position the pump so that the high-pressure plumbing is aligned vertically and horizontally, and the rear of the pump is 1–2 in. (3–5 cm) from the control cabinet. |

Figure 551

| 11. | Attach the assembled u-shape nipple [1] to the pump high-pressure outlet OUT connection [2] and hand-tighten. |

Figure 552

| 12. | Verify the gland nut [2] is set approximately to the depth of the nozzle stand-off tool [1]. |

Figure 553

| 13. | Adjust the position of the bracket [1], then tighten the bracket. |

Figure 554

| 14. | Lock the pump wheels [1]. |

Figure 555

The jaws of the crowfoot must maintain a 90-degree angle to the horizontal axis of the torque-wrench handle throughout the torquing rotation. Other angles of orientation can alter the set torque.

Figure 556

| 15. | Torque the pump connection. |

Figure 557

| 16. | Attach the bracket cap [1] and tighten. |

Move the conduit out of the way so that it is not trapped under the bracket.

Figure 558

| 17. | Flush the high-pressure plumbing, see Flush the High-Pressure Plumbing. |

| 18. | Reset the pump, see Reset the Pump. |

| 19. | Install the nozzle, if removed, see Install the Nozzle, perform a nozzle test, and see Test the Nozzle. |

Maintain the High-Pressure Fittings

Nipples contain small caps to protect the threading and keep debris from entering the high-pressure plumbing during shipment. Remove the caps before assembling the high-pressure plumbing fittings. Do not use pliers to remove the black caps or cut the black caps from the nipple. Pliers and knives can damage the nipple threads causing leaks and water damage.

When preparing the ProtoMAX high-pressure tubing, it is important to follow instructions. Some high-pressure tubing and fittings are pre-assembled. Fittings may need readjustment during installation to make sure proper seals and eliminate potential leaks. Use the provided stand-off tool to make sure the fittings are correctly seated and sealed.

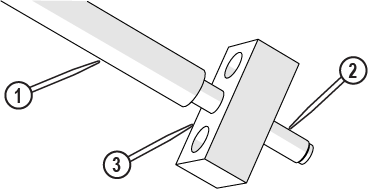

High-pressure fitting connections are located on the ends of the high-pressure nipple at the back of the machine. The high-pressure fittings consist of the following components.

Figure 559

| [1] Conduit | [2] High-pressure nipple | [3] Bar clamp | [4] Bar clamp screw (x 2 per bar clamp) | [5] 90-degree fitting |

| 1. | Thoroughly clean all high-pressure components before disassembly. |

| 2. | Release any pressurized water from the high-pressure lines, see Prepare the High-Pressure Lines for Repair. |

Always loosen the high-pressure bar clamp screws evenly (1/4–1/2 turn at a time). Unevenly loosening the fitting can damage the tapered nipple or concave fitting and can cause leaks in the high-pressure fitting.

| 3. | Remove the bar clamp [1]. |

| 4. | Replace the component and reassemble high-pressure connections. |

If replacing the high-pressure nipple at the nozzle or pump, see High-Pressure Gland Nut Assembly.

| a. | Place the high-pressure line [2] in the conduit [1] (Figure 561). |

| 5. | Seat the high-pressure nipple [1] into the high-pressure fitting [2] and secure with the bar clamp and screws. |

Figure 562

| 6. | Tighten the bar clamp screws [1] evenly. |

Always tighten the bar clamp screws evenly (1/4–1/2 turn at a time) to the correct torque to make sure the high-pressure nipple seats correctly. Do not overtighten the bar clamp screws. Over tightening the screws can damage the high-pressure nipple tapered edge or the concave high-pressure fitting and damage the high-pressure seal. Damaged high-pressure seals can cause the connection to leak.

Figure 563

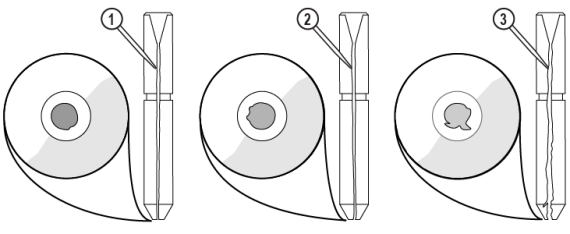

There is a small, even space [1] between the bar clamp and the high-pressure fitting when correctly torqued.

Figure 564

| 7. | Flush the high-pressure plumbing, see Flush the High-Pressure Plumbing. |

| 8. | Reset the pump, see Reset the Pump. |

| 9. | Install the nozzle, if removed, see Install the Nozzle, perform a nozzle test, and see Test the Nozzle. |

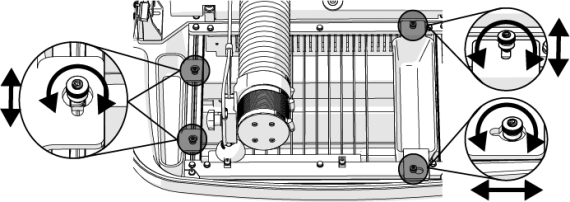

Lubricate the Lead Screws and Linear Rails

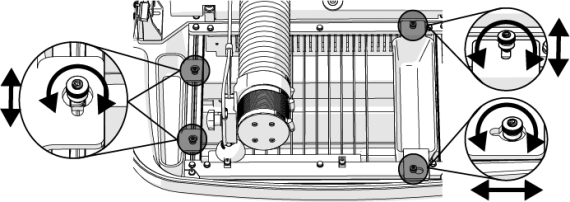

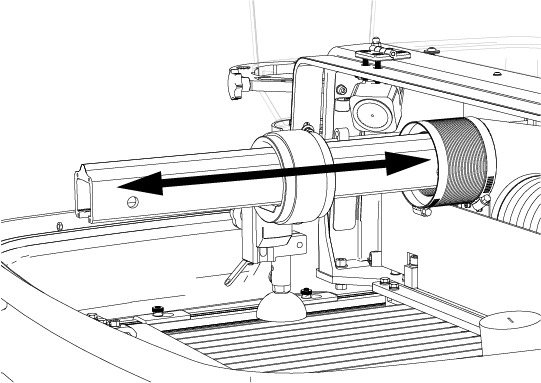

The X- and Y- axes lead screws should be lubricated periodically to make sure smooth and quiet operation. The X-and Y-axes linear rails should be inspected, cleaned, and lubricated periodically. See the Maintenance Schedule for the recommended frequency for this task.

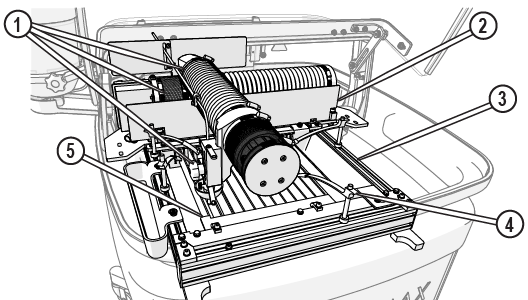

Lubricate the Y-Axis Lead Screw and Linear Rail Bearing Carriage

| 1. | Open the lid and lock it in the upright position. |

Use care when opening or closing the lid to avoid injury. Never let the lid free-fall. Keep hand, fingers, or body parts away from the side of the table when closing the lid.

| 2. | Move the Z-axis to the middle of the cutting deck. |

| 3. | Turn OFF the machine and close MAKE. |

To avoid damage, do not use flammable liquids or other chemicals to clean the equipment.

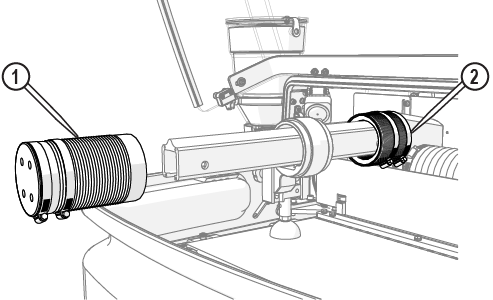

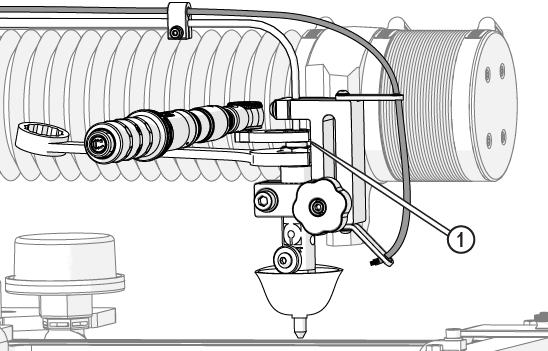

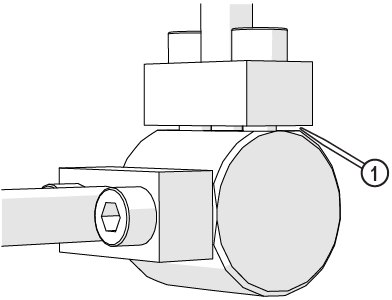

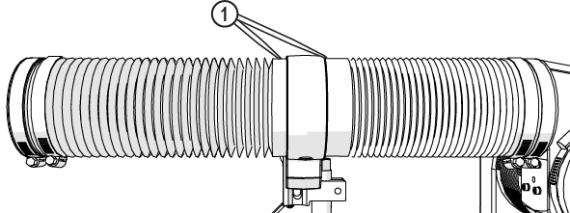

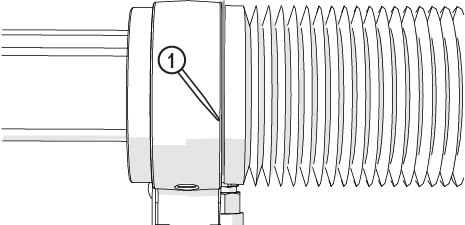

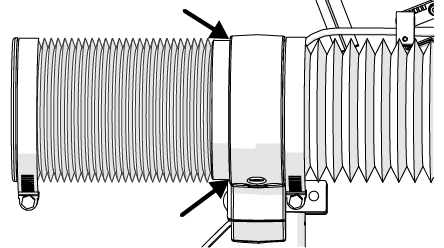

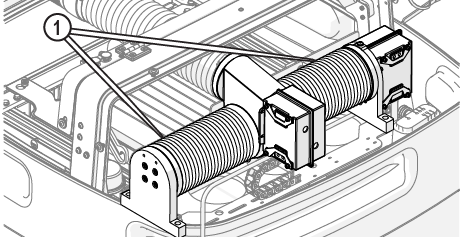

| 4. | Rinse and wipe away all debris from the bellows [1]. |

Figure 565

| 5. | Place a piece of cardboard on the cutting deck to keep components or tools from falling in the catcher tank. |

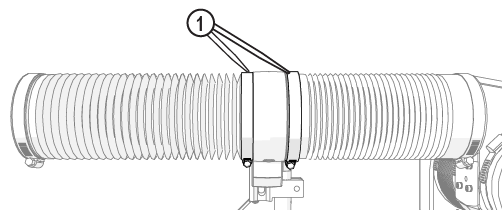

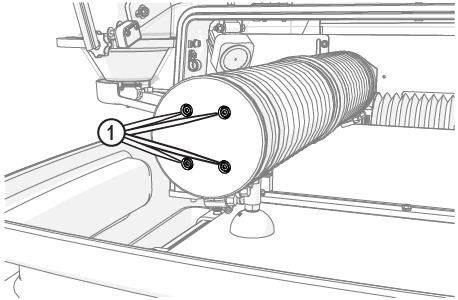

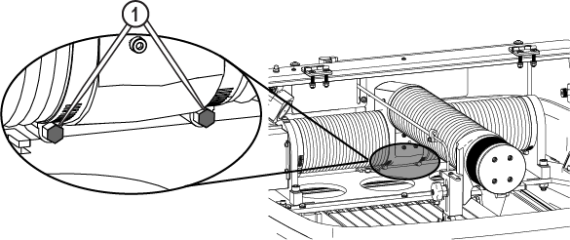

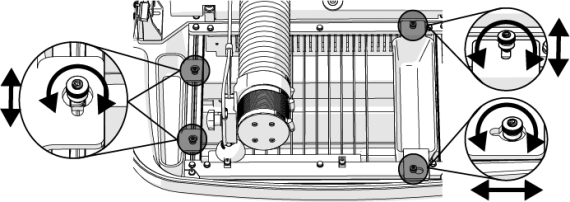

| 6. | Loosen the center clamps [1]. |

Do not move the bellows away from the Y-axis carriage. The area around the Y-carriage must be clean of debris to prevent erosion damage to the internal components.

Figure 566

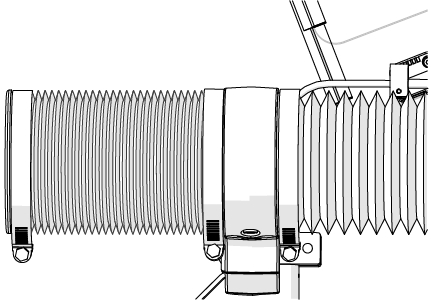

| 7. | Push up on the bottom of the clamps [1] to loosen, then slide the clamps toward the ends. |

Clamps can stick to the bellows. To prevent damage to the bellows, use care when removing the clamps.

Figure 567

| 8. | Wipe the bellows ends [1] and Y-axis carriage with a clean rag; remove all debris. |

Figure 568

| 9. | Remove the end cap screws [1] and set aside. |

Figure 569

Use care when removing the bellows from the Y-axis carriage. Ripping or tearing of the bellows ends can allow debris in the Y-axis and can cause damage to the internal components.

| 11. | Slide the rear bellows [2] from the Y-axis carriage (Figure 570). |

| 12. | Clean all debris from around the lead screw nut [1] with a dry, soft cloth. |

Figure 571

| 13. | Apply a light coat of lubricant, approximately a 1/8 in. bead, along the length of the lead screw [1]. |

Figure 572

| 14. | Turn ON the machine and open MAKE. |

| 15. | Using MAKE, move the Y-axis the full length of travel three times. |

Figure 573

| 16. | Wipe off any excess lubricant. |

| 17. | Close MAKE and turn OFF the machine. |

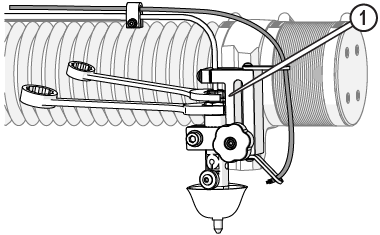

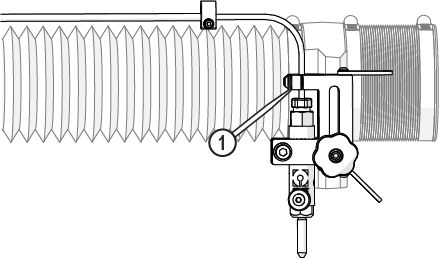

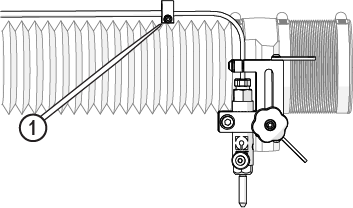

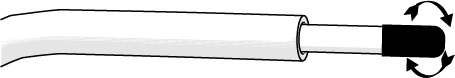

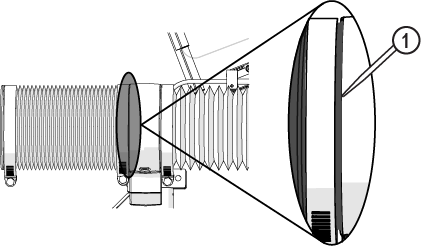

Rotating the bellows helps to eliminate rub marks or holes on the interior of the bellows, prolongs the bellows life. If needed, loosen the clamp at both ends of the bellows, rotate the bellows approximately 90 degrees then secure with the clamps.

| 18. | Reattach the rear bellows to the Y-axis carriage, pulling the bellows lip over the Y-axis carriage edge. |

Ensure there is an even gap [1] between the Y-axis carriage housing and the bellows lip to keep debris from entering into the bellows and causing damage to the interior components.

Figure 574

| 19. | Secure the bellows with the clamp [1]. |

Make sure the bellows cuff does not move away or come off while tightening the clamp.

Figure 575

| 20. | Turn ON the machine, move the Z-axis forward until it reaches the hard stop. |

| 21. | Turn OFF the machine. |

Figure 576

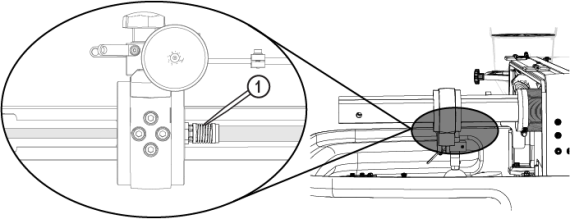

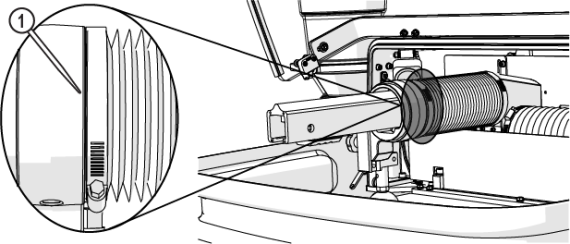

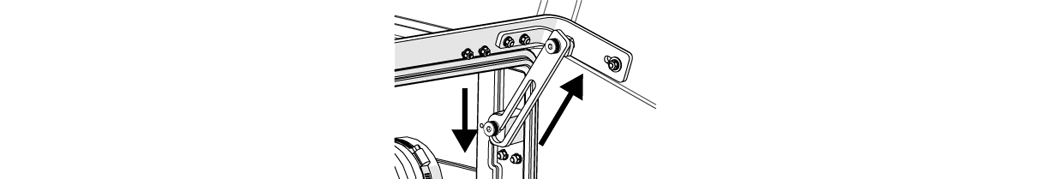

| 22. | Identify if the lead screw support bracket configuration, then complete the applicable procedure. |

| • | If there is access [1] to the grease port, go to Lubricate the Y-Axis Linear Rail Bearing Carriage with Grease Port Access. |

Figure 577

| • | If there is no access [1] to the grease port, go to Lubricate the Y-Axis Linear Rail Bearing Carriage without Grease Port Access. |

Figure 578

Lubricate the Y-Axis Linear Rail Bearing Carriage with Grease Port Access

| 1. | Attach the grease gun nipple to the grease fitting [1]. |

Figure 579

Do not apply excessive grease to the linear rail bearing carriage. Pumping excessive amounts of grease into the carriage can displace the carriage lip seal [1].

Figure 580

| 2. | Pump grease into the linear rail bearing carriage until grease appears at any location along the edge of the carriage [1]. |

| 3. | Attach the Y-axis end cap and bellows, see Attach the Y-Axis End Cap and Bellows. |

Lubricate the Y-Axis Linear Rail Bearing Carriage without Grease Port Access

| 1. | Remove the lead screw support bracket [1]. |

Figure 582

| 2. | Identify if the linear rail bearing carriage has a set screw [1] or grease fitting [2]. |

If there is a grease fitting, complete Step 3. If there is a set screw, complete Step 4.

| 3. | Lubricate linear rail bearing carriage with a grease fitting. |

| a. | Attach the grease gun nipple to the grease fitting. |

Do not apply excessive grease to the linear rail bearing carriage. Pumping excessive amounts of grease into the carriage can displace the carriage lip seal [1].

Figure 584

| b. | Pump grease into the linear rail bearing carriage until grease appears at any location along the edge of the carriage [1]. |

| 4. | Lubricate linear rail bearing carriage without a grease fitting: |

| a. | Remove the set screw [1]. |

Figure 586

| b. | Insert the grease gun needle into the set screw port. |

| c. | Pump grease into the linear rail bearing carriage until grease appears at any location along the edge of the carriage [1] (Figure 581). |

To avoid damaging the linear rail bearing carriage, do not over tighten the set screw.

| d. | Replace the set screw and tighten it. |

| 5. | Move the Z-axis to the rear of the cutting deck. |

To prevent damage to the lead screw support bracket and other internal components, do not over tighten the lead screw support bracket.

| 6. | Install the lead screw support bracket [1], ensuring the end of the lead screw is secured in the support bracket. |

Figure 587

| 7. | Attach the Y-axis end cap and bellows, see Attach the Y-Axis End Cap and Bellows. |

Attach the Y-Axis End Cap and Bellows

| 1. | Using MAKE, move the Z-axis forward, approximately 5–6 inches from the front hardstop. |

| 2. | Reattach the end cap and bellows. |

Rotating the bellows helps to eliminate rub marks or holes on the interior of the bellows, prolongs the bellows life. If needed, loosen the clamp at both ends of the bellows, rotate the bellows approximately 90 degrees then secure with the clamps.

Figure 588

Figure 589

| 3. | Pull the front bellows to the Y-axis carriage, pulling the bellows lip over the y-axis carriage, ensuring there is an even gap all around the y-axis carriage. |

Figure 590

| 4. | Attach the clamp, confirm the gap around the Y-axis carriage then tighten the clamp. |

Figure 591

| 5. | Verify the bellows cuff [1] has not pulled away from the carriage housing. |

Figure 592

| 6. | Move the Y-axis forward and backward three full strokes to distribute the lubricant along the lead screw. |

Figure 593

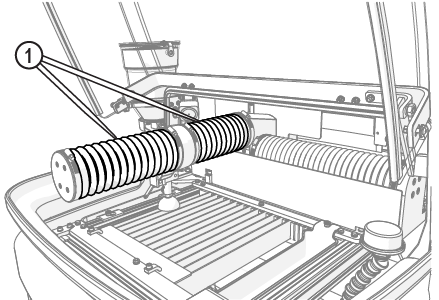

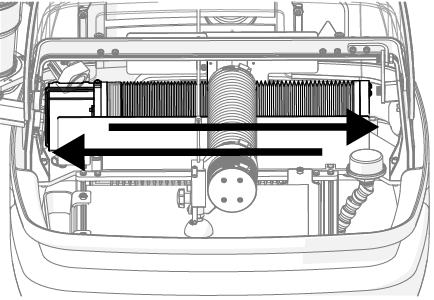

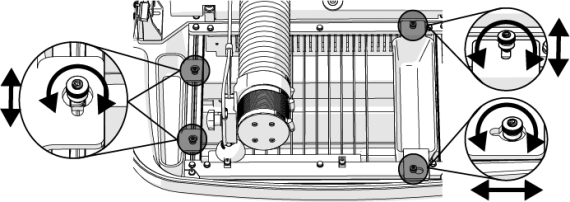

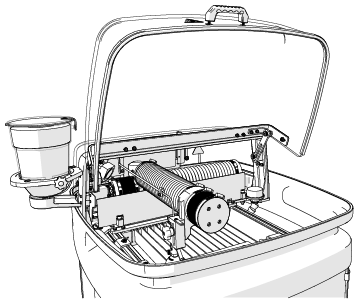

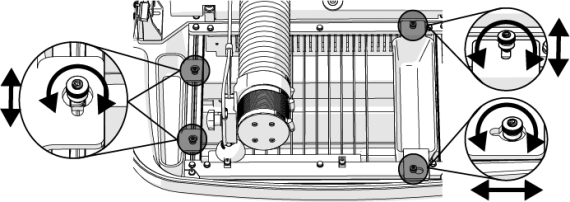

Lubricate the X-Axis Lead Screw and Linear Rail Bearing Carriages

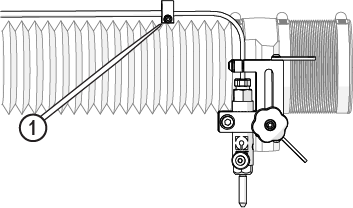

| 1. | Remove the bellows protector splash shield [1]. |

Figure 594

| 2. | Move the Y-axis to the middle of the cutting deck. |

| 3. | Turn OFF the machine, close MAKE, and close the front lid. |

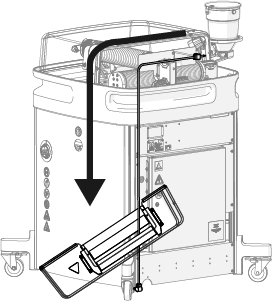

| 4. | Remove the screws and washers [1] securing the rear lid and set aside. |

Figure 595

| 5. | Lift the lid, then slide it down the high-pressure plumbing to the floor. |

To prevent scratches to the lid, place it on a soft surface.

Figure 596

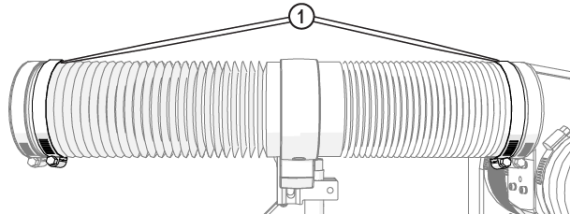

| 6. | Rinse and wipe away all debris from the bellows [1]. |

Figure 597

| 7. | Place a piece of cardboard on the cutting deck to keep components or tools from falling in the catcher tank. |

Do not move the bellows away from the X-axis carriage. The area around the X-carriage must be clean of debris to prevent erosion damage to the internal components.

| 8. | Loosen the center clamps [1]. |

Figure 598

Figure 599

| 9. | Push up on the bottom of the clamps to loosen, then slide the clamps toward the ends. |

| 10. | Wipe the bellows ends [1] and X-axis carriage with a clean rag; remove all debris. |

| 11. | Move the bellows to the ends of the axis and clean all debris from around the lead screw nut [1] with a dry, soft cloth. |

Figure 600

| 12. | Apply a light coat of lubricant, approximately 1/8 in. bead, along the length of the lead screw [1], then spread the lubricant along the lead screw surface. |

Figure 601

Figure 602

| 13. | Turn ON the machine, open MAKE, then move the X-axis to one side. |

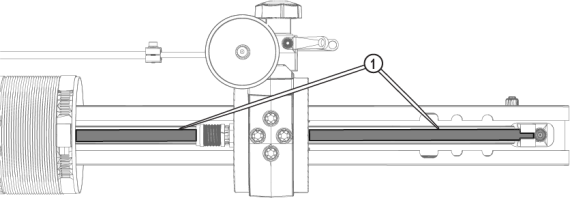

| 14. | Identify if the linear rail bearing carriage has a set screw [1] or grease fitting [2], then complete the appropriate step. |

Figure 603

| 15. | Lubricate linear rail bearing carriages with a grease fitting: |

| a. | Attach the grease gun nipple to the grease fitting. |

| b. | Pump the grease into the linear rail bearing carriage until it comes out the edges [1]. |

| 16. | Lubricate linear rail bearing carriages without a grease fitting: |

| a. | Remove the set screw. |

| b. | Insert the grease gun needle into the set screw port. |

| c. | Pump the grease into the linear rail bearing carriage until it comes out the edges [1] (Figure 604). |

To avoid damaging the linear rail bearing carriage, do not over tighten the set screw.

| d. | Replace the set screw and tighten it. |

| 17. | Reattach the bellows to the X-axis carriage, pulling the bellows lip [1] over the carriage edge [2]. |

Rotating the bellows helps to eliminate rub marks or holes on the interior of the bellows, prolongs the bellows life. If needed, loosen the clamp at both ends of the bellows, rotate the bellows approximately 90 degrees then secure with the clamps.

Make sure there is an even gap [1] between the X-axis carriage housing and the bellows lip to keep debris from entering into the bellows and causing damage to the interior components.

Figure 606

| 18. | Secure with the clamp. |

| 19. | Replace the bellows protector splash shield [1]. |

Figure 607

If needed, clean the cable track area before replacing the rear lid. See Clean the Cable Track.

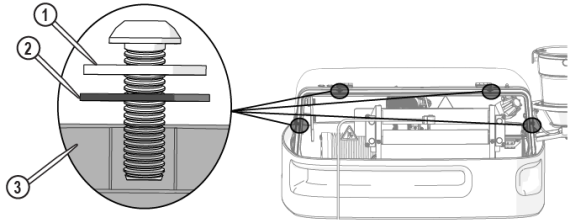

| 20. | Replace the rear lid and secure with the screws and washers (x 4) (Figure 608). |

To prevent damage to the lid [3], place the rubber washer [2] between the lid and the metal washer [1]. Do not over tighten the screw.

| 21. | Move the X-axis side to side three full strokes to distribute the lubricant along the lead screw. |

Figure 609

Use care when opening or closing the lid to avoid injury. Never let the lid free-fall. Keep hand, fingers, or body parts away from the side of the table when closing the lid.

| 22. | Close the lid. |

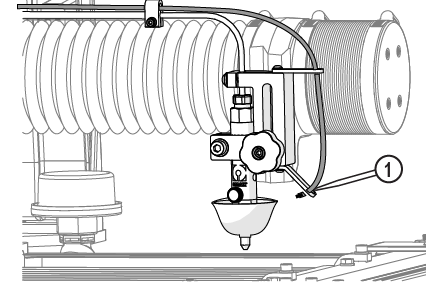

Clean the ProtoMAX

Do not use chemicals when cleaning the machine unless specified in the instructions. Chemicals can damage the machine or interfere with operation.

Keeping the ProtoMAX equipment clean and maintained is essential for long-term operation. Use care when cleaning the equipment because the particles used in abrasive waterjet machining are abrasive. The following instructions focus on best practices for cleaning the machine. A basic cleaning step is included as part of the equipment shutdown checklist, but cleaning the cutting deck area is recommended after cutting a part.

Abrasive waterjet cutting, by its nature, is a messy process. When cutting parts, abrasive in the jet stream erodes the material that is being cut. All of the water and particles create a sludge that builds up in and around the cutting area. Additionally, the mist from the cutting process accumulates on the inside of the cutting deck enclosure. Using the nozzle splash guard is a best practice for helping to keep the machine clean.

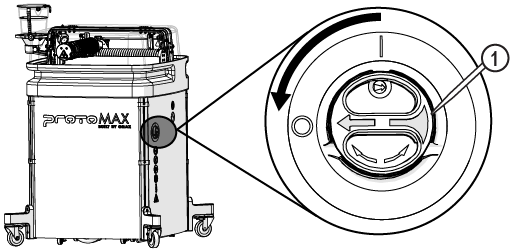

Remove the Accumulated Garnet

Since garnet abrasive and metal particles continually accumulate in the tank, regularly scheduled removal of accumulated deposits is necessary. When removing garnet abrasive material from the bottom of the tank, it is best to completely drain the water from the tank before attempting to remove the garnet abrasive waste. The drier the garnet abrasive, the easier it is to remove.

Used garnet abrasive by itself is not toxic and can be taken to a dump site or disposed of normally. However, if any hazardous materials were cut, the garnet abrasive waste becomes subject to several environmental regulations. Contact the local officials for proper disposal methods.

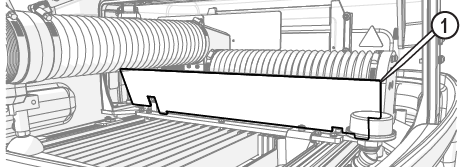

Clean the Garnet Bins

The garnet bins capture some of the spent particles introduced into the catcher tank during the cutting process. Particles settle into these bins rather than accumulate in the catcher tank. See the Maintenance Schedule for the recommended frequency for this task.

To avoid damage, do not use flammable liquids or other chemicals to clean the equipment.

Use care when emptying the bins. To avoid damage to the bins, do not strike the bins against objects or use sharp instruments to remove garnet from the bins.

| 1. | Open the lid and lock it in the upright position. |

Use care when opening or closing the lid to avoid injury. Never let the lid free-fall. Keep hand, fingers, or body parts away from the side of the table when closing the lid.

| 2. | Lower the water in the catcher tank to below the thumbscrews. |

| 3. | Spray a strong stream of water on the thumbscrews to remove all debris. |

| 4. | Loosen the thumbscrews and remove the garnet bins. |

Figure 610

| 5. | Rinse the garnet bins until clean. |

| 6. | Replace the garnet bins and tighten the thumbscrew. |

| 7. | Close the lid. |

Clean the Lid

To avoid damage, do not use flammable liquids or other chemicals to clean the equipment.

The lid contains the steam, mist, and particles emitted while cutting. Cutting underwater and using the nozzle splash guard helps limit the amount of particle emission into the enclosure. Cleaning the lid after each cut is a best practice. See the Maintenance Schedule for the recommended frequency for this task.

Figure 611

| 1. | Open the lid and lock it in the upright position. |

Use care when opening or closing the lid to avoid injury. Never let the lid free-fall. Keep hand, fingers, or body parts away from the side of the table when closing the lid.

| 2. | Gently spray the inside of the lid with water to rinse off accumulated abrasive and other particles. |