Change the Crankcase Oil

Change the crankcase oil according to the intervals specified in the Maintenance Schedule to avoid excessive wear and damage to the crankcase bearings. The oil must also be changed anytime it becomes contaminated with water or other debris.

Recommended oil:

- Type: SAE 30 non-detergent (ISO 100)

- Amount: 40.6 ounces (1.2 liters)

- Operating condition: All operating temperatures

Using other types of oil can shorten pump life and void the warranty.

| 1. | Disconnect the pump, see the Prepare the Pump for Maintenance section. |

| 2. | Remove the pump cover. |

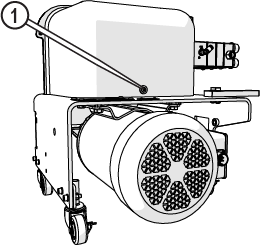

| a. | Remove the front screw [1] and set aside. |

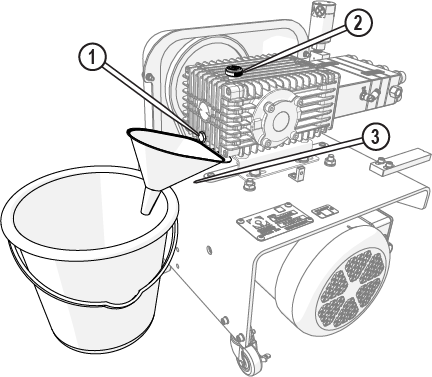

Figure 716

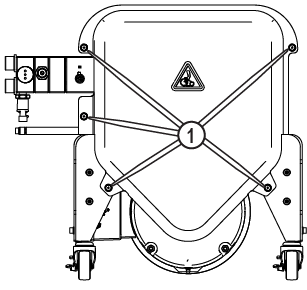

| b. | Loosen the captive screws [1] and remove the front crankcase cover. |

Figure 717

| 3. | Place a rag between the pump crankcase drain plug (Figure 718) and the frame [3] to catch oil drips. |

Crankcase oil can be hot. Be careful when removing the plug to prevent hot oil from flowing out and burning hands or fingers.

| 4. | Place a funnel and bucket below the crankcase drain plug (Figure 718). |

| 5. | Loosen or remove the oil filler port cap [2] (Figure 718). |

| 7. | Allow the oil to drain completely. |

Always dispose of used oil according to local environmental regulations.

| 8. | Replace the crankcase oil drain plug. |

| 9. | Fill with the correct amount of oil through the oil filler port. |

| 10. | Replace the oil filler port cap [2] (Figure 718). |

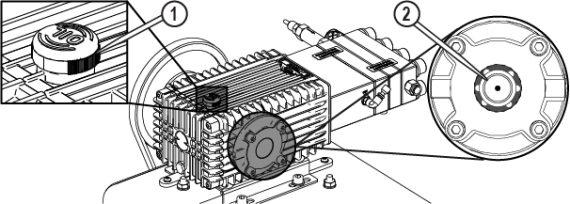

| 11. | Check the oil level, do one of the following. |

| • | Remove the dipstick [1] and make sure the oil level is at the full mark. |

| • | Make sure the oil level is at the top of the sight glass [2]. |

Figure 719

| 12. | Wipe any spilled oil from the crankcase and frame. |

| 13. | Replace the pump cover. |

| 14. | Reconnect the pump, see Place and Connect the Pump. |

| 15. | Reconnect the high-pressure plumbing, see Connect the High-Pressure Plumbing. |

| 16. | Reset the pump, see Reset the Pump. |

| 17. | Replace the side panels, see Install the Side Panels. |