Lubricate the Y-Axis Linear Rail Bearing Carriage without Grease Port Access

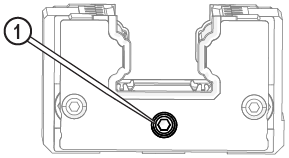

| 1. | Remove the lead screw support bracket [1]. |

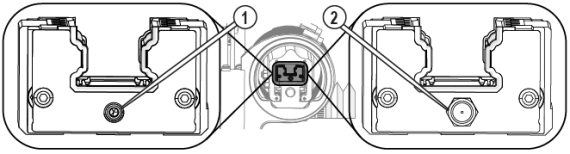

Figure 831

| 2. | Identify if the linear rail bearing carriage has a set screw [1] or grease fitting [2]. |

If there is a grease fitting, complete Step 3. If there is a set screw, complete Step 4.

| 3. | Lubricate linear rail bearing carriage with a grease fitting. |

| a. | Attach the grease gun nipple to the grease fitting. |

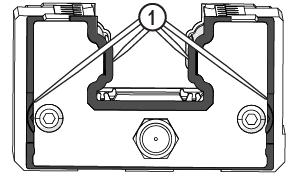

Do not apply excessive grease to the linear rail bearing carriage. Pumping excessive amounts of grease into the carriage can displace the carriage lip seal [1].

Figure 833

| b. | Pump grease into the linear rail bearing carriage until grease appears at any location along the edge of the carriage [1]. |

| 4. | Lubricate linear rail bearing carriage without a grease fitting: |

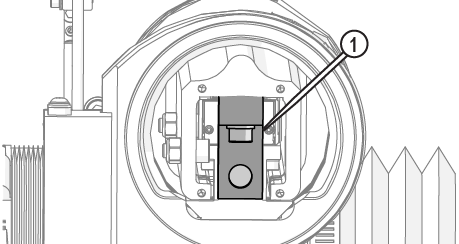

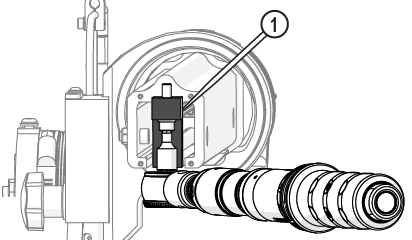

| a. | Remove the set screw [1]. |

Figure 835

| b. | Insert the grease gun needle into the set screw port. |

| c. | Pump grease into the linear rail bearing carriage until grease appears at any location along the edge of the carriage [1] (Figure 834). |

To avoid damaging the linear rail bearing carriage, do not over tighten the set screw.

| d. | Replace the set screw and tighten it. |

| 5. | Move the Z-axis to the rear of the cutting deck. |

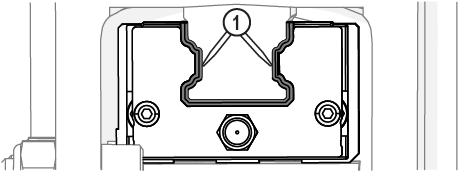

To prevent damage to the lead screw support bracket and other internal components, do not over tighten the lead screw support bracket.

| 6. | Install the lead screw support bracket [1], ensuring the end of the lead screw is secured in the support bracket. |

Figure 836

| 7. | Attach the Y-axis end cap and bellows, see Attach the Y-Axis End Cap and Bellows. |