Using Intelli-MAX® Proto MAKE Software

Introduction to MAKE

MAKE software controls your ProtoMAX abrasive waterjet system by sending precise motor control commands to move the nozzle along your part's cutting path, while controlling the timing and flow of abrasive and high pressure water. The help topics built into MAKE provide the information needed to operate the software's cutting functions.

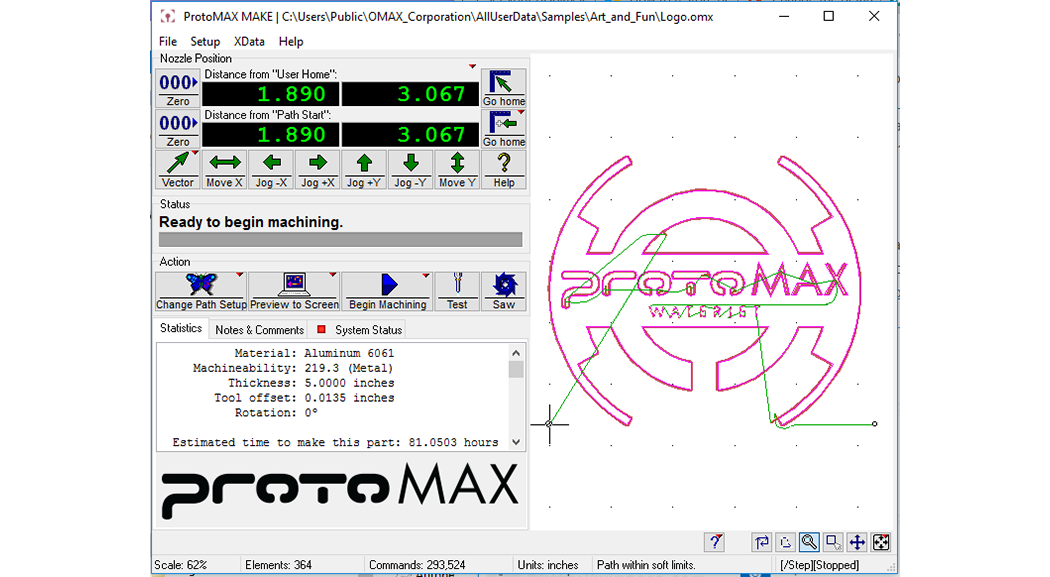

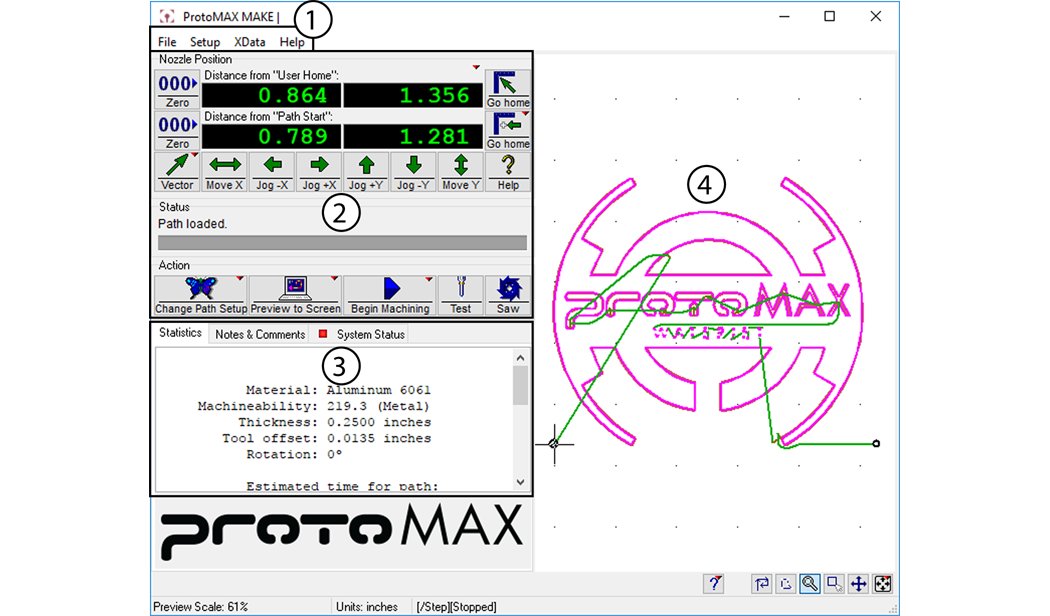

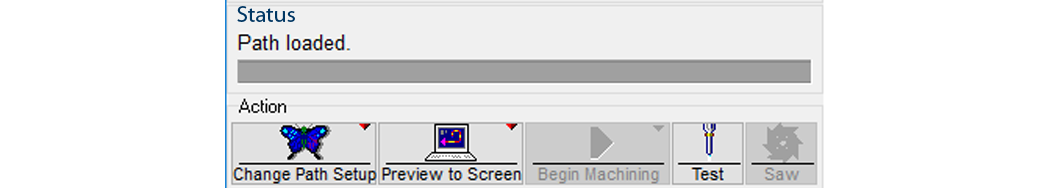

An example of a part being prepared for cutting using ProtoMAX MAKE

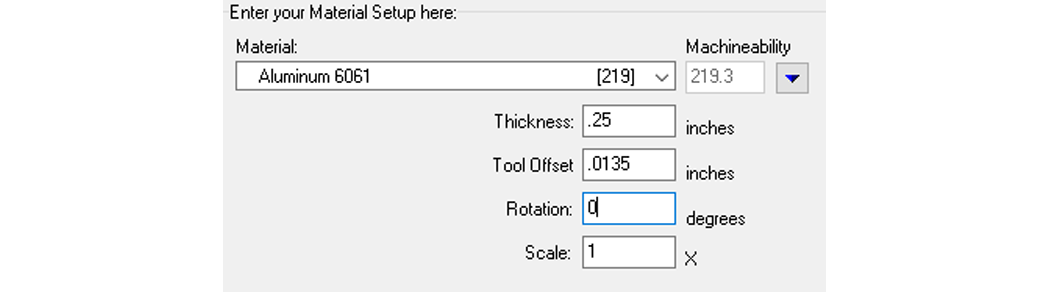

MAKE also sets machine controls that specify the material setup parameters for each part you cut:

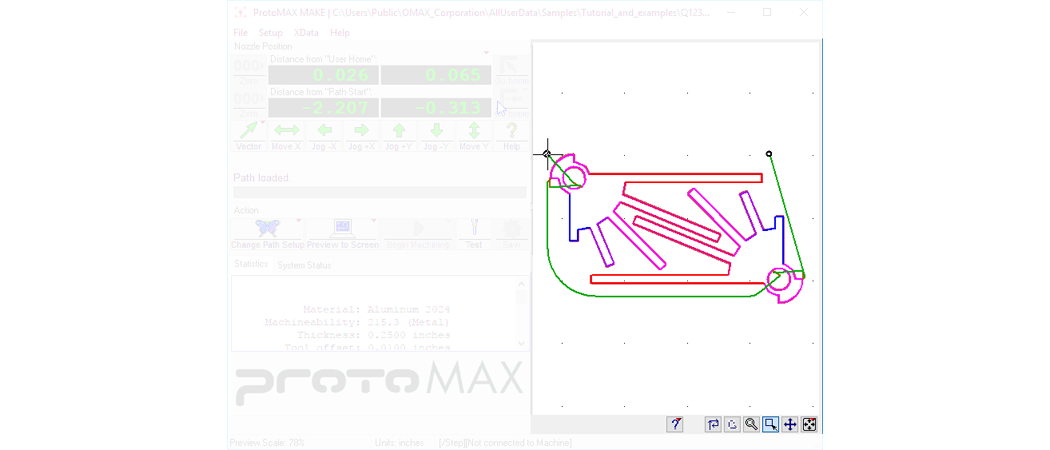

Material setup information required by ProtoMAX MAKE

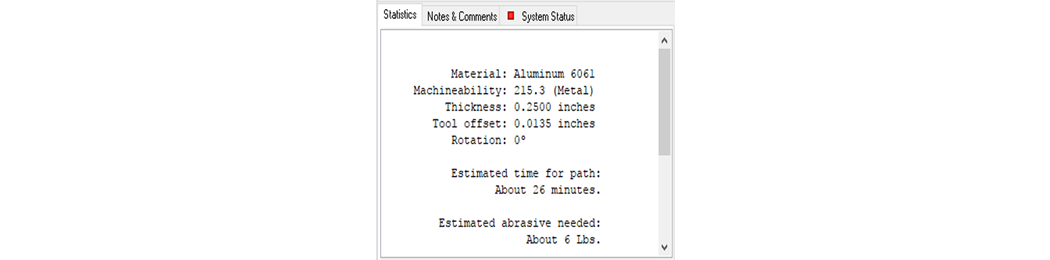

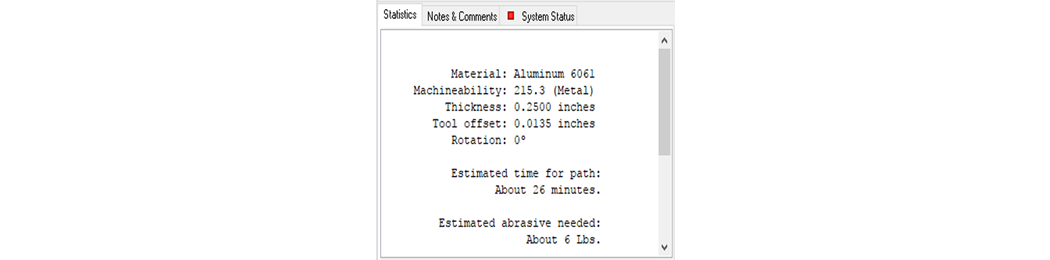

MAKE can also track system operational status, provide important part cutting statistics, and enable you to record notes and comments for later reference:

MAKE statistics report example

The MAKE User Interface Window

The MAKE user interface displays the following ProtoMAX information:

1 - Main Menu

2 - Machining Controls

3 - Statistics, notes & comments, and System Status

4 - Part Display Window

Main Menu

The ProtoMAX main menu provides access to these operational functions in MAKE:

- Opening and configuring files

- Printing the part or part statistics

- Configuring display and zoom settings

- Defining how XData is presented

- Accessing the ProtoMAX Help system

Part Display Window

The part display section of the MAKE window shows the OMX file that's currently open and tracks the nozzle position while the part is cutting and provides a set of Zoom Tools for positioning and viewing specific part details:

MAKE Positioning Controls

The nozzle position controls allow movement of the cutting head in the X and Y directions:

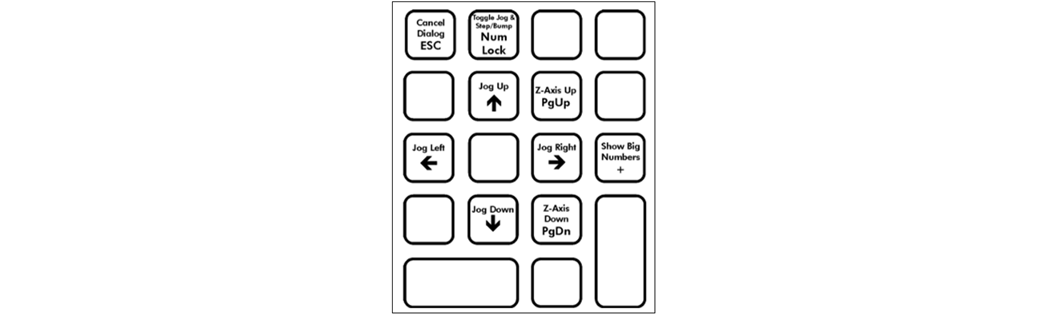

Keys are also provided on your keyboard's numeric keypad when Num Lock is off to jog the position of the cutting nozzle:

The nozzle position refers to a specific point on the machine where the nozzle is located. The nozzle position location point is referenced using X-Y coordinates that measure their distance from a specific reference point (called a "Home").

All points in the grid have an associated X-Y coordinate

Nozzle Position Display

The nozzle position display shows the distance (X and Y) from where the nozzle is currently positioned to a specific Home location.

The top row for X distance always displays the generic User Home. The second row for X distance displays Path Start Home.

Machining Controls

The following machining controls are available via ProtoMAX MAKE Status and Action displays:

Statistics Window

The ProtoMAX Statistics Window provides specific statistics about the part file being used. Right-clicking the Statistics display provides a drop-down menu with printing options.

- Material type

- Machinability

- Material thickness

- Tool offset

- Rotation

- Time to MAKE the part

- Cost to MAKE the part

- Estimated abrasive needed

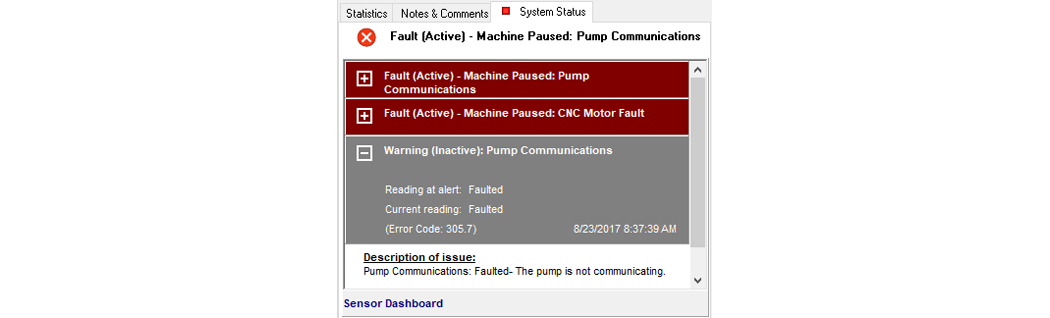

System Status

The System Status tab provides user alerts identifying issues that affect or prevent machine operation. In addition to user alerts, a description of the alert along with a suggesting for correcting the situation are provided.