Etching Procedures

This topic describes how to create a pilot hole and how to use XData to create deeper etches.

How to create a pilot hole with Etch

Use the Etch quality to create a pilot hole for later drilling. The jet stream acts as a center punch.

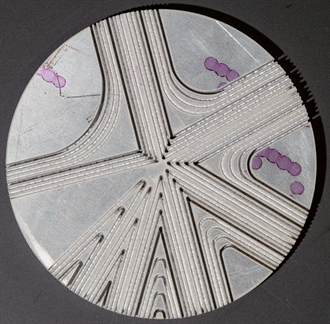

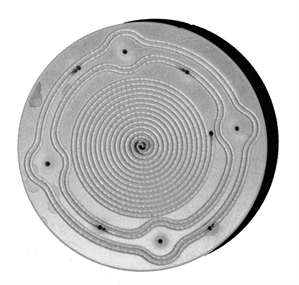

The following image shows four pilot holes. A tiny etch was used as the center point for the pilot hole.

- Click the Line Draw command.

- On the drawing, click the location of where you want the line to start.

- In the Specify Dimensions dialog, in the Lengthbox, enter 0.001 in. (0.025 mm).

- In the Angle box, enter 0 or 90. Click OK.

- On the LAYOUT Toolbar, click Quality and select Etch.

- Click on the line. The color will change to gray, indicating that it has the Etch quality.

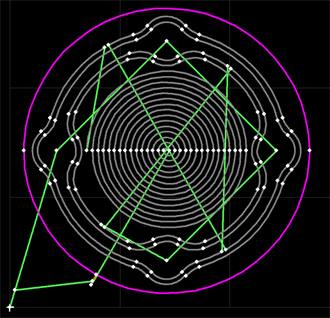

Hover the mouse over the following image to see inquire details on the etch entity.

Advanced Users: XData

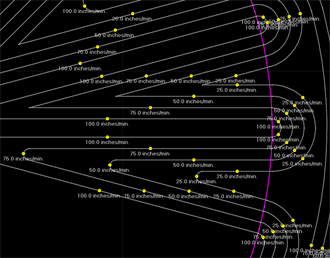

By default, etching runs at the top speed of the ProtoMAXmachine, 100 in. per minute (2540 mm per minute). Advanced users might consider using XData to override the speed of etching in order to control the depth of the etch by slowing it down. Use XData to set an exact speed for more control.

To set XData 014: Force absolute speed:

- Open Layout.

- Open an image or draw one or more an entities.

- Click select and select one or more entities.

- Under XData, select Edit XData for Selected.

- Select the Show advanced XData items check box.

- From the Choose Command menu, select [014]: Force absolute speed.

-

In the box labeled Enter absolute speed value in inches/min, enter between 1 (slowest speed) and 100 (fastest speed).

Note: The base speed is 50 IPM (1270 mm per minute).

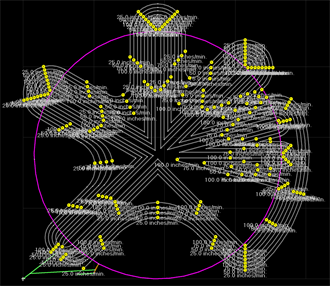

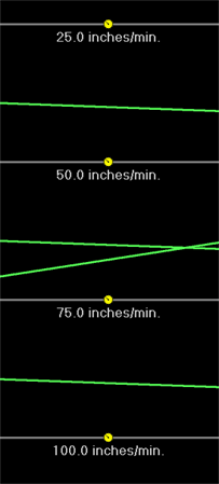

The slower the speed, the deeper the etch. The yellow circles indicate XData numbers.

- Click OK.

Angle Coin with XData

The angle coin is a tool used to see how far the etch digs into the material while traversing angles and radii.

- Each etch line is composed of four different speeds to help understand how the etching will affect the material and overall quality of the etch.

- When the nozzle moves into a corner or small radii it must slow down, causing the etch to be very deep in those spots.