![]()

________________________________________

Doing a "dry run"

The ProtoMAX can go through the motions of making a part

The ProtoMAX can go through a "dry run" of a part, that is, go through all the motions of making the part without using water or abrasive.

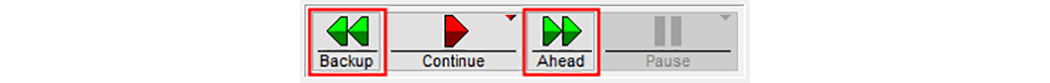

The most simple way to do a "dry run" is to click the Backup and Ahead buttons on the Path Control panel.

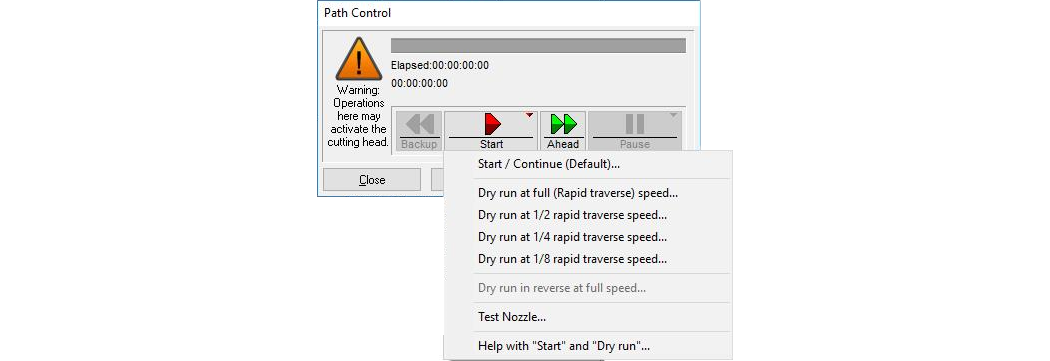

For specific speeds, right-click the button to display a drop-down menu.

Right-click Start to view this menu

A dry run is useful to check that the machining head will not strike any fixturing, or run into the material when it makes the part. When working with uneven material, be sure to move the nozzle to the appropriate stand-off distance to see if the nozzle strikes the material.

This menu displays the following

Start/Continue (Default)

This starts or continues making the part with full water pressure and abrasive. The ProtoMAX will operate in its normal mode.

Dry run at full (1/2, 1/4, 1/8) rapid traverse speed

This causes the machining nozzle to go through the motions of making the part, but with no water or abrasive. Choose how quickly it moves as a fraction of the rapid traverse speed.

Always pause the ProtoMAX before adjusting your fixturing. The machining head is heavy and can crush body parts against fixtures.

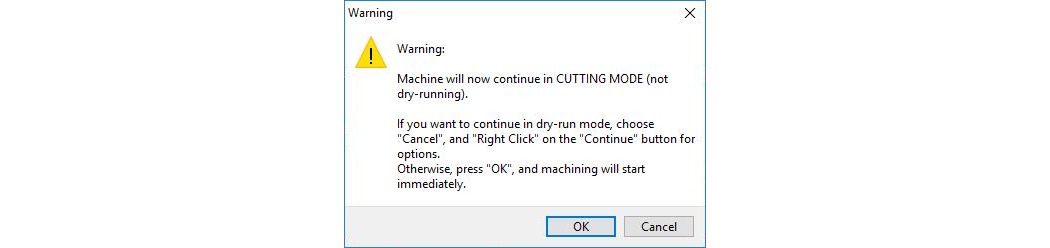

If machining is paused to adjust material or fixtures, right-click and choose the dry run speed again. Click , and the ProtoMAX will begin operation using full water pressure and abrasive. The warning shown in the next figure will appear if you click after doing a dry run:

Dry run in reverse at full speed

Use the option to "backup" along the tool path. This is useful when a fixture has been adjusted to check that part of the tool path will still clear the fixture.

Test nozzle

This brings up the Test Pump and Nozzle dialog, where you can test the pump and abrasive flow or flush out the high-pressure plumbing with the nozzle removed to purge out any foreign debris typically required following plumbing maintenance.