What is Quality?

Each entity in LAYOUT is assigned a "Quality," which affects how the piece is machined on the ProtoMAX.

The Quality directly affects how quickly the abrasive jet head moves when it makes a piece. The slower the abrasive jet head moves, the higher the Quality. At the highest Quality (a Quality of 5), the abrasive jet head moves most slowly.

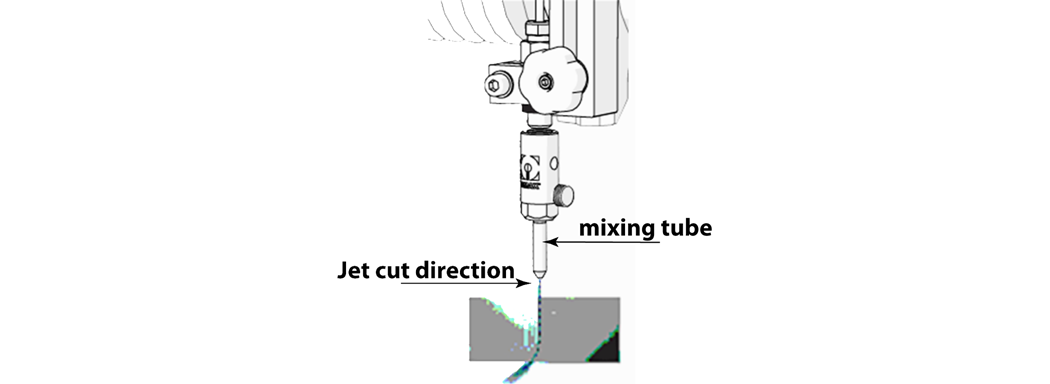

This figure shows how the abrasive jet stream curves as it moves through the material.

The Quality always takes into account the material being used. When working with polypropylene, for example, using a Quality of 5 moves the abrasive jet head much faster than when working with steel. The Quality is always relative to the machineability of the material.

Quality also takes into account the geometry of the part. When cutting intricate curves, for example, the machining speed may slow down to maintain the same Quality as when cutting a straight line.

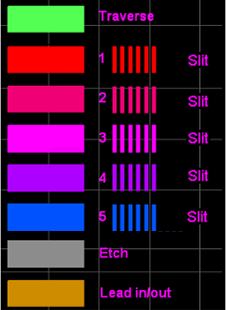

Whenever an entity is added to the ProtoMAX, it is assigned a Quality of 0 and a color of green. This is known as a "traverse" line, because abrasive and water are both turned off while the abrasive jet head traverses the entity. Traverse lines are used to position the head for the next piercing of the material.

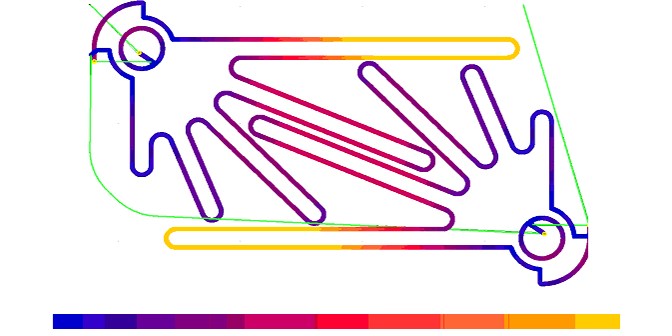

Most of the time, Quality is assigned to entities in a drawing using the Quality command in LAYOUT. Each type quality is color-coded, from red for Quality 1 to blue for Quality 5, as well as gray for Etch.

The Quality colors

Other OMAX machines (GlobalMAX, MAXIEM, and OMAX) have additional qualities supported, though if one opens a file from one of those machines in the ProtoMAX software, those qualities may be replaced with the nearest supported substitute

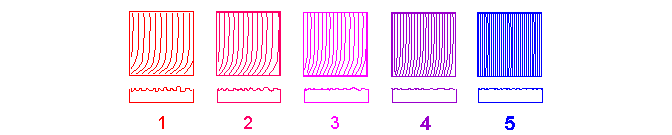

Qualities 1 through 5 use abrasive and water to pierce the material. A Quality of 1 will pierce all the way through a material. Because the abrasive jet head is moving quickly, however, the surface finish obtained with a Quality of 1 is rougher than that obtained with a Quality of 5 (which is a smooth finish).

Most high tolerance parts are cut at quality of 3, as this provides a good balance between machining speed, surface finish, and precision.

Notice also that as the Quality numbers get lower, the surface finish gets rougher.

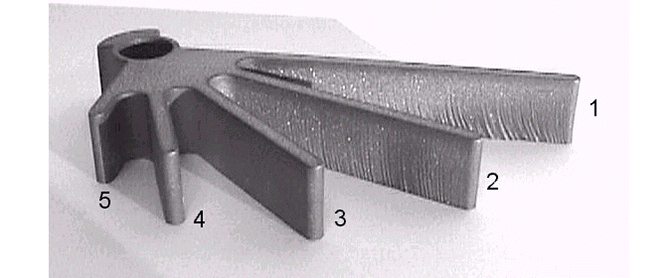

Each leg of this part was made at a different Quality

Blue (Slowest cutting speed) Yellow (Fastest Speed)

The different speeds for each Quality, shown graphically

In most cases, setting the Quality is a compromise between getting the best surface finish in the least amount of time. When first using the ProtoMAX on a particular material, a Quality of 3 is a good Quality to choose. If the finish is too rough, increase the Quality. If the finish is acceptable, try lowering the Quality to see if the part can be made in less time.

Sometimes a Quality of 1 will not cut all the way through a piece. This is normal because Quality of 1 means, "Just barely cut all the way through." If the nozzle is not in tip-top shape, there will be a slight attachment between a part and the scrap. This may occur in spots here and there around the edge of the part.

For this reason, Quality of 1 is reserved as a "Special Case" quality for fine tuning, and for advanced users. Use Quality of 2 for most fast machining.

Likewise, Quality of 5 is overkill for most machining practices, and should be reserved for special cases for the advanced user.

On the ProtoMAX, Quality can be used to adjust for wear on the machine. When cutting, if you find you do not get the surface finish required, choose a higher or lower quality until you do.

Surface Quality does not correspond to tolerance. A Quality of 3 is the recommended Quality for most applications.