![]()

________________________________________

Recover from a Nozzle Clog

There are multiple scenarios resulting from a clog in the nozzle. The fix depends on how far water has traveled back up the abrasive feed tube and whether the water entered the abrasive hopper or not. In all scenarios, correct the condition that caused the nozzle to clog, such as wet garnet, a blocked orifice, a blocked mixing tube, or other before continuing operation.

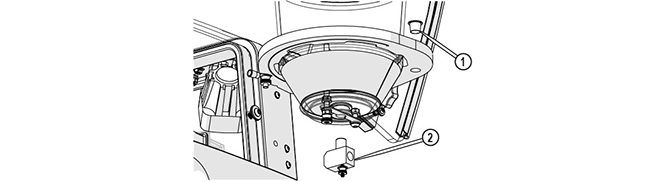

1. Remove the garnet abrasive feed tube from the nozzle assembly [2] and the garnet abrasive feed block [1].

2. Use clean, dry air to completely clear the clog from the abrasive feed tube.

3. If the water entered the abrasive feed block, remove the hopper splash guard.

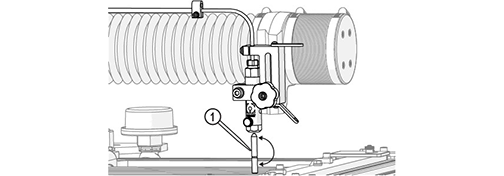

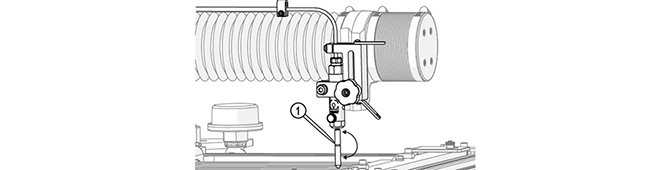

4. Remove the hopper ground strap [1].

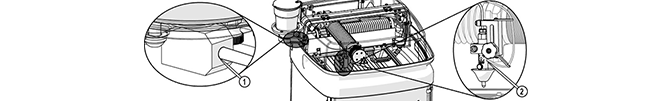

5. Remove the abrasive feed block [2] and insert the red plug [1] to prevent garnet from pouring out from the bottom of the hopper assembly.

6. Use clean, dry air to completely blow out all debris, clumps, or clogs from the abrasive feed block. If the water entered the hopper assembly:

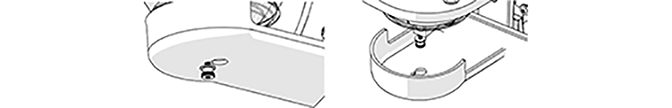

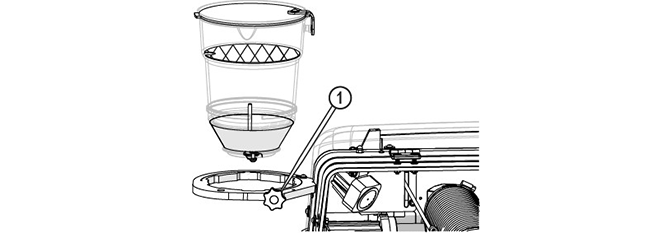

7. Loosen the knob [1] and remove the hopper assembly from the hopper support plate.

8. Completely empty and wipe out the hopper.

Make sure the hopper container is completely dry prior to filling with dry garnet abrasive. The hopper screen may not sufficiently remove moist clumps from the wet abrasive.

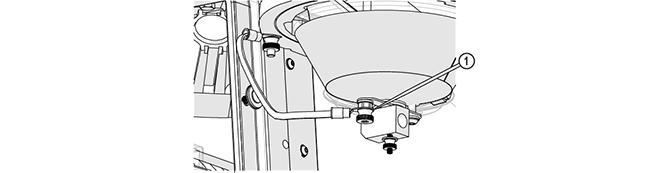

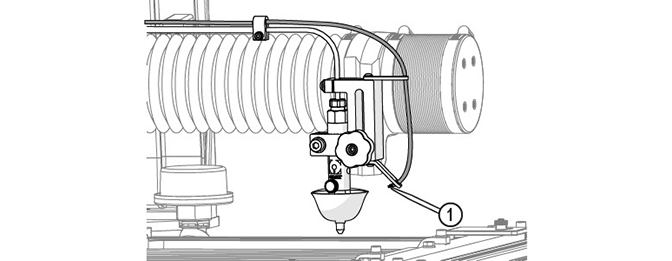

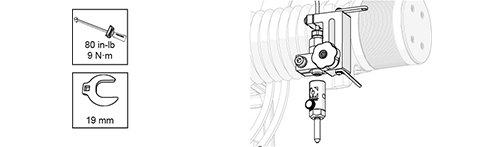

9. Remove the abrasive feed tube [1] from the nozzle body and place it over the Y-axis.

10. Remove the nozzle body assembly [2] from the nozzle inlet body [1].

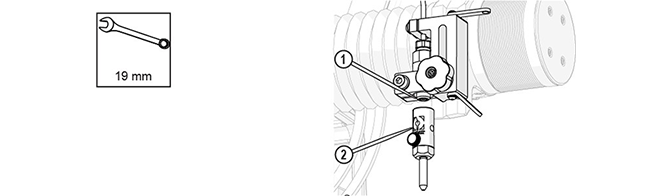

11. Remove the orifice assembly [1] and inspect the chamber bore [2].

12. Clean the orifice assembly and the nozzle body (including the air vent hole) thoroughly prior to reassembly. Once the nozzle is completely clean:

13. Insert the orifice assembly into the nozzle body and re-install the nozzle assembly on the nozzle inlet body.

NOTICE

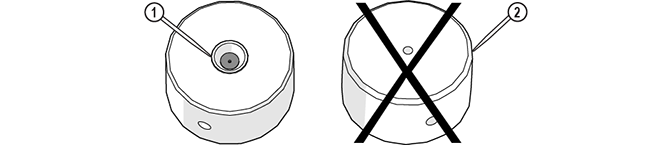

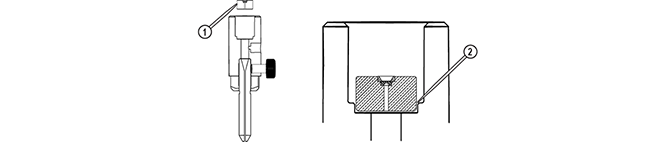

Always orient the orifice assembly so the brass [1] is visible from the top of the nozzle body. Inserting the orifice assembly in nozzle body in the incorrect orientation [2] may cause damage to the orifice assembly.

14. Close the Path Control window.

15. Position the nozzle towards the center of the tank (off the material) between two slats.

16. Open the Test dialog box and run a nozzle test to dislodge the clog.

If the nozzle test does not remove the clog:

17. Remove the nozzle splash guard and mixing tube [1], turn the mixing tube upside down and insert it back into the nozzle body and tighten it.

18. Conduct a nozzle test to dislodge the clog.

19. Remove and replace the mixing tube [1] in the proper orientation in the nozzle body.

20. Re-install the hopper and its components (abrasive feed block, feed tube, ground strap, and hopper splash guard.

21. Fill the hopper with fresh, dry abrasive.

22. Connect the abrasive tube to the nozzle body.

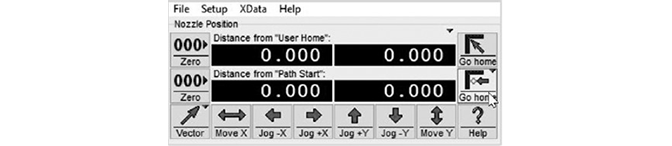

23. To continue cutting the part, using MAKE: Click Go Home in the Path Start Home dialogue.

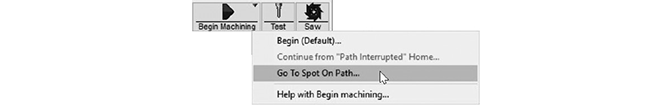

24. Right-click Begin Machining.

25. Click Go to Spot on Path.

26. Move the cursor over the spot on the tool path slightly before the clog occurred and left click.

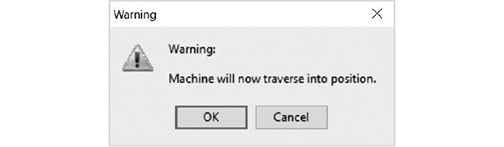

27. Click OK on Machine will now traverse into position dialog box.

28. Click Continue to start cutting.

If nozzle clogging continues, it may be necessary to replace the abrasive feed tube, the mixing tube, nozzle orifice, and/or nozzle filter as one or more of these components may be causing the problem.