![]()

________________________________________

Prepare to Cut the Part

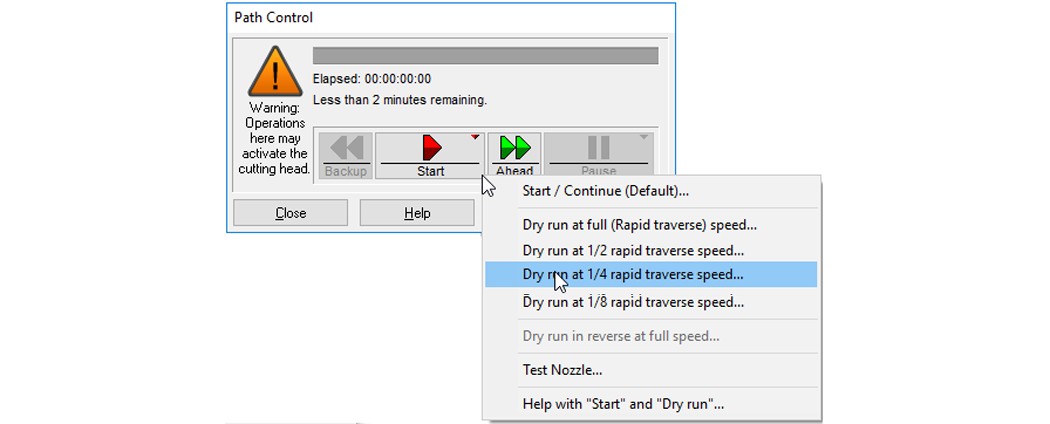

Do a Dry Run of the Tool Path

A dry run that follows your tool path should always be done prior to doing the actual cut for the following reasons:

- It goes through all the cutting motions without turning on the water or abrasive

- Does a quality check prior to cutting the part

- Verifies the part will fit on the material

- Verifies the start point

- Verifies the nozzle will not hit any fixturing

- Verifies the nozzle stand-off is sufficient so the nozzle won’t run into the material (if surface is uneven)

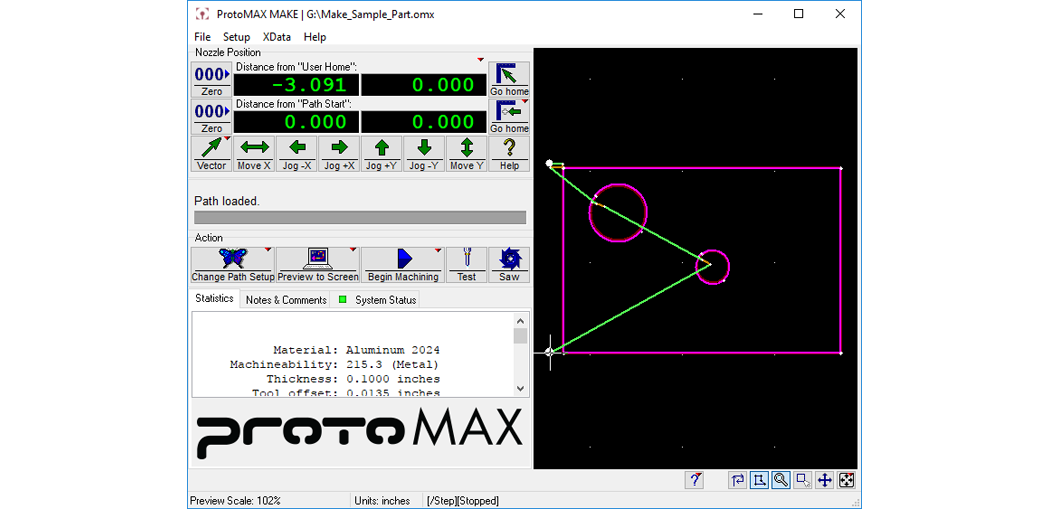

1. Ensure the drawing for the part to be cut is opened.

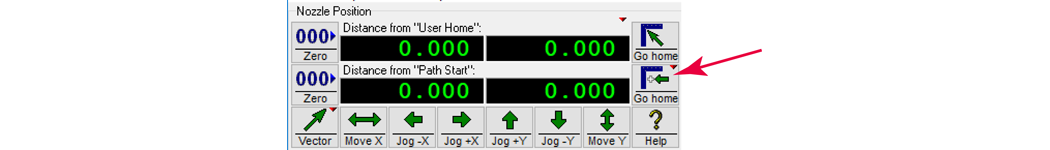

2. Click Go home to move the nozzle back to the Path Start Home position.

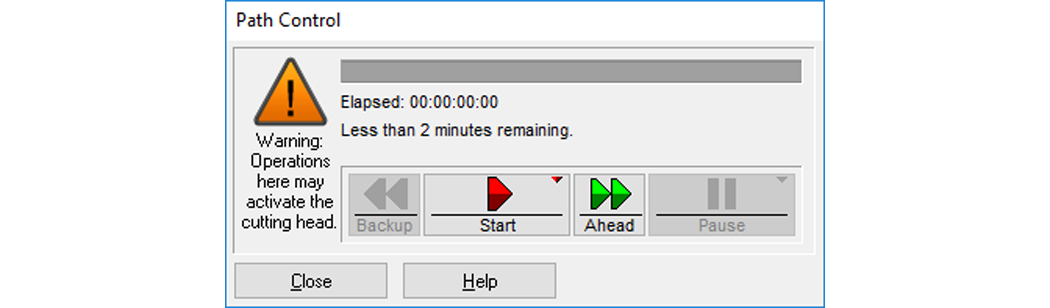

3. Click Begin Machining to display the Path Control window:

4. Right-click the Start button to display a list of dry run options.

5. Click Dry run at 1/4 rapid traverse speed...

6. At any time, click Pause if potential problems are seen during the dry run process; this stops nozzle movement

7. When the dry run is finished, click the Close button to close the Path Control window.