![]()

________________________________________

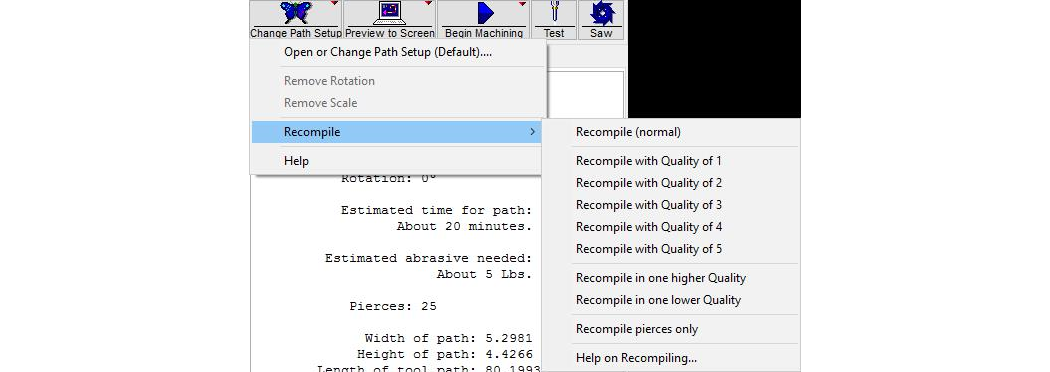

Recompiling

Recompile a part in any Quality

Use the Recompile command to assign all cuts on a part to the same Quality. Traverse lines and lead-in/outs are unaffected, but all other entities are set to the Quality you choose. Use Recompile for quick time studies (to examine the difference between making the part in Quality 3 and Quality 4, for example). It is also useful if to quickly make a part with a different Quality.

When “recompiling” in another quality, only the cutting qualities are changed (Qualities 1,2,3,4,5).

To Recompile a Part

1) Right-click on the Change Path Setup button.

2) Move the cursor over the Recompile choice, and another pop-up menu appears.

3) Choose the Quality you want to recompile the part in.

If "Recompile (normal)" is chosen, the part is recompiled with all the original Quality settings.

Recompile in one higher or lower Quality

Select Recompile in one higher Quality or Recompile in one lower Quality to recompile all cutting entities (Qualities 1 through 5) to one quality higher or lower than the qualities selected in the original drawing.

Recompile Pierces Only

The selection Recompile pierces only will recompile the part and keep only the traverses and lead-ins and lead-outs. This can be useful in the following situations:

- When using a pump that is not dual pressure capable, you can still pierce at low pressure pierce by manually lowering the pump pressure, piercing all the leads, then raising the pressure and cutting the actual path. This can also be useful for low pressure dynamic piercing, and later cutting at full pressure.

- Use the OMAX to quickly pierce the holes needed to feed a wire in a wire EDM that would otherwise be slow to pierce its own holes.

- One of the ways to get maximum precision is to use a very low stand-off. (Generally speaking, the closer you can go the less taper will occur.) However, if the stand-off is too low, then the jet will clog during piercing, and water will go up the abrasive feed line. With the pre-pierce option, set the stand off to a height that is good for piercing, and pierce all the holes. Then set the stand-off to just barely avoid touching the material, and cut the part. (Be careful when setting the stand-off this low, however, as if the material is not uniform thickness, the nozzle may drag.)

This command is not compatible with all tool paths, however. Here are the kinds of paths that may give trouble:

- Parts that have slots (like Newt_2_with_one_pierce.ord), where the lead-in and the lead-out do not attach to the same location.

- Parts that don't start or end with a rapid traverse move.

- Parts that don't use quality of Lead i/o for the leads.