ProtoMAX®

Maintenance, Storage

OMAX Corporation

21409 72nd Avenue South

Kent, WA USA 98032

Information:

Technical Support:

E-Mail:

Web:

This document contains subject matter to which OMAX® Corporation has proprietary rights. Recipients of this document shall not duplicate, use, or disclose information contained herein, in whole or in part, for any use other than the purpose for which this manual was provided.

OMAX Corporation believes the information described in this manual is accurate and reliable. From time to time, design improvements will be made to the OMAX equipment. Photographs, text, and sketches within the body of this manual may not exactly represent your equipment. In general, this manual contains the most up-to-date information available. However, OMAX Corporation cannot accept any responsibility, financial or otherwise, for any consequences arising out of the use of this material. The information contained herein is subject to change, and revisions may be issued to advise of such changes or additions. OMAX strives to continually improve user documentation. If you have any questions or concerns about the content of this user’s guide, please e-mail us at tech_writing@omax.com, or contact us by mail at:

OMAX Corporation

Technical Publications

21409 72nd Avenue South

Kent, WA, USA 98032

OMAX Corporation is continually improving their equipment to bring you the best in abrasive waterjet machining technology. For that reason, your abrasive waterjet may differ slightly from what is described in this document. If you have any questions, please feel free to contact us at 1-800-298-4036 or e-mail us at info@protomax.com. You can also receive technical support on-line at: Web: http://www.protomax.com.

Original Instructions in English

September 2019

© 2019 OMAX Corporation

Important Safety Information

SAFETY IS YOUR RESPONSIBILITY.

For your own safety, read this guide thoroughly and carefully before the equipment is installed, operated, maintained, or issues are troubleshooted.

Save these instructions.

This guide contains important safety information for the equipment. Careful compliance with the safety information helps prevent physical injury, damage to the equipment, and can extend the equipment's life.

Equipment safety features, safety glasses, hearing protection, and more can reduce potential injury. Be careful when the equipment is installed, operated, and maintained. Safety guards and features do not guarantee your safety if you are careless, inattentive, or use poor judgment. If it feels dangerous, do not try it.

YOU ARE RESPONSIBLE FOR YOUR SAFETY IN YOUR SHOP.

Machine Safety Labels

These safety labels can appear on the equipment. If ignored, physical injury, death, or equipment damage may occur. Read the complete safety information in the operation, installation, or maintenance guide before the equipment is installed, operated, or maintained.

WARNING Electrical Shock

Dangerous voltages. Do not access areas with this label before the applicable safety precautions are done; lockout/tagout the power and make sure there is no voltage on the circuits before installation, maintenance, or other work is done.

WARNING Airborne Debris

Eye protection and hearing protection are required during operation. Do not remove the abrasive feed tube from the nozzle or hopper when pressurized. The pressure can blow abrasive into the air, and the abrasive particles can get into the eyes and contaminate tools and machines.

WARNING Keep Fingers and Hands Away From Parts that Move

Keep hands and fingers away from the machine when it moves and during operation. Fingers and hands can be crushed and cut by machine parts when they move. Do not try to gain access to the machine or parts during operation.

WARNING Pinch Risk

Keep hands away from the edge of the catcher tank when the lid is closed.

WARNING Keep Hands Away From Jet

Do not put hands or fingers near the nozzle during operation. Immediately get medical aid for abrasive waterjet injuries. Injuries caused by high-pressure abrasive waterjet systems are dangerous. Do not wait to get medical aid!

WARNING Watch Hands and Fingers

Always keep the motor guards in position during operation. Keep hands away from belts and pulleys during maintenance and service.

Electrostatic Discharge

Attention! Be careful when electrostatic-sensitive devices are touched. Use electrostatic discharge protection procedures.

No Open Flame

Do not smoke near the equipment. Do not operate the equipment in an explosive atmosphere. Make sure ignition sources (such as flames or electrostatic discharge) are not near the equipment. Do not store flammable materials near the equipment. Do not use equipment in or around flammable gases or liquids. Do not let explosive or flammable vapors collect in the area around the equipment. Make sure there is good airflow in the work area to dissipate gases, vapors, and fumes. Be especially careful when machining materials that create sparks, such as titanium, which can cause gases in the catcher tank to explode.

Do Not Operate With Guard Removed

Do not operate when the guards or panels are removed.

Do Not Spray

Do not spray water on or near the machine's electrical enclosure.

Do Not Step

Do not step, stand, or walk on the slats. The slats can become weak after operations and can fall under more weight.

Read Manual First/Do Not Adjust

Do not adjust. Read the manual. Special instructions could be required before adjustments are made. Adjustments to the equipment can have unwanted effects and cause injury or damage.

MANDATORY ACTION Disconnect Power

Always disconnect the primary power cord from the electrical source to isolate the machine from its electrical supply.

Read Manual

Read the equipment operation guide for important safety information and operation instructions. Do not operate this machine until all safety precautions and operation instructions are read and understood.

Wear Hearing Protection

Always wear hearing protection when near the equipment during operation. When operated above water, noise levels can exceed 70 dBA.

Wear Eye Protection

Always wear approved safety glasses when the abrasive waterjet system is operated. Other types of glasses do not give sufficient eye protection! The garnet abrasive is not a chemical irritant, but garnet can cause an eye injury like sand if it is not quickly flushed. Also, the catcher tank water can contain particles from the material or other chemical irritants. Have an eye-wash station near the work area if the abrasive spray gets into the eyes.

Read the product labels and refer to product Safety Data Sheets (SDS) to identify the properties and risks of chemical products and materials referenced in this document. Use good industrial hygiene, safety practices, and personal protective equipment identified in the SDS.

Wear Gloves

The catcher tank water can have dangerous bacteria in it. A small break in the skin can introduce the dangerous bacteria into a wound. Always wear protective gloves if there are cuts or wounds on the hands or fingers. When material is put on or removed from the slat bed, wear gloves that give protection against sharp metal edges.

Read the product labels and refer to product Safety Data Sheets (SDS) to identify the properties and risks of chemical products and materials referenced in this document. Use good industrial hygiene and safety practices. Use personal protective equipment as specified in the SDS.

Safety Precautions

Safety instructions must be followed when the equipment is installed, operated, or maintained. If ignored, death or physical injury can result, or damage can occur to the equipment. Always follow the applicable safety precautions when work is done with this equipment.

Use the equipment ONLY for its intended function

- Read the installation manual before the equipment is set up to learn about important installation and safety information.

- Read the documentation for recommended accessories. The use of incorrect accessories can cause a risk of injury to persons or damage to equipment.

- Wear eye and hearing protection. Always wear ISO-approved impact safety glasses.

- Make sure the equipment is installed correctly before the system is started.

- Never stand on the equipment. Serious injury can occur if the machine tips or you touch the machining tool during operation.

Do not make changes

- Do not make changes to the equipment or components that are not approved.

- Changes to the equipment can cause a risk of physical injury to the operator and others and can cause damage to the equipment or other property. Changes to the equipment will void the warranty.

- Do not change, defeat, or bypass the equipment safety features.

Do not remove panels

- Do not remove the panels during operation. Only remove them when required by maintenance or to troubleshoot problems.

Check for damaged parts

- Before the equipment is used, carefully examine guards or other parts that are damaged to make sure that it operates correctly and functions as intended. Examine to make sure parts that move, move freely, are aligned correctly, are not broken, are mounted correctly, and for other conditions that can have an effect on its operation. Replace guards or other damaged parts.

Use caution, stay alert, and be attentive

- Do not install, operate, or service the equipment while under the influence of alcohol or drugs. Read the warning labels on prescription and over-the-counter drugs. If in doubt, do not install or operate the machine.

- Do not install, operate, or service the equipment when you are tired.

- Always follow the safety precautions when the equipment is installed, operated, maintained, or serviced. Carefully operated, the abrasive waterjet is a safe tool. When operated carelessly, serious injury can result.

- Wear a face or dust mask.

- Do not reach over the machine to operate it. Keep feet on the floor and balanced at all times.

- Keep a minimum of 16 in. (40 cm) away from pressurized equipment during operation.

- Do not try to tighten the ultra high-pressure (UHP) fittings when the system is pressurized.

Keep the tools and equipment in good condition

- Keep machine and accessories clean for the best and safest performance.

- Always keep the equipment in good condition.

- Follow the maintenance instructions for equipment and accessories.

- Keep all protective guards and stop devices.

Keep the equipment and area around the equipment clean and free from clutter

- Remove all installation, operation, or maintenance tools from the equipment before it is operated.

- Keep the work area clean and clutter-free to prevent accidents.

- Keep the equipment clean for the best performance.

Do not operate the equipment in a dangerous environment

- Do not use the equipment in or around flammable gases or liquids.

- Do not expose the equipment to rain or use it outdoors.

- Keep the equipment in a bright work area.

Never leave the equipment unattended during operation

- Always stop and turn off the equipment before leaving the area.

- Keep visitors at a safe distance from the work area.

- Keep children away from the equipment work area.

- Do not let children play around or operate the equipment or its components.

Never operate the equipment without safety guards or covers

- Do not change, bypass, or try to defeat the safety guards, covers, or switches.

- Keep the guards in position and in working order.

- Do not remove the safety cover or guard during operation.

- Know the location of the ON/OFF switch.

- Know how to disconnect the primary power supply to the equipment.

- Start and operate the machine only when all side panels are in position.

Never put your hands in the area of the nozzle during operation

- Seek immediate medical aid for all waterjet injuries. Injuries caused by high-pressure abrasive waterjets are serious. Do not wait!

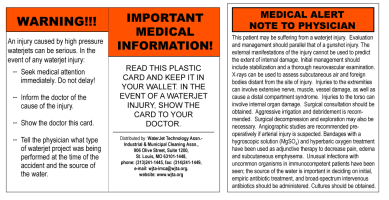

- Refer to the WaterJet Technology Association (WJTA) warning card for important medical aid information.

Figure 949

Be careful when material(s) is moved in the catcher tank

- Do not operate the equipment when material is moved into the catcher tank.

- Always stop the abrasive waterjet before adjustments are made to the material or the abrasive jet.

- Always be careful when material is moved into the catcher tank. Fingers can be caught between a heavy part and the support slats.

- Be careful around the support slats. The abrasive waterjet also cuts the support slats; the edges can become sharp and cause cuts or collapse.

Do not touch live electrical components or parts

- Always use a licensed electrician or approved person to install the primary power source to use with the machine.

- Examine the equipment power and control cables regularly for correct connection and installation. Damaged, exposed, and bare wires can cause electrocution or death!

- Make sure the equipment is correctly connected and grounded in accordance with the national, state, and local codes. Do not remove the prongs from the plug. Always plug into the correct electrical outlet.

- Never use any electrical plug adapter.

- Make sure the power switch is in the OFF position before the equipment is plugged in to stop accidental starts.

- Always disconnect the equipment from the primary power before service or maintenance work is done.

Noise Emission Precautions

Environmental factors, such as how the room or structure is built, other machines and power tools in the area, and other noise sources, can have an effect on the environment's true noise level. When installed and operated correctly, the equipment's A-weighted emission sound pressure level, LpA , is less than 75 dBA (LpA < 75 dBA). Therefore, OMAX recommends that the operator wear hearing protection during equipment operation.

Treat All Injuries with Caution

Injuries that involve contact with the catcher tank water should receive medical aid immediately. Refer to the WJTA Warning Card for important medical aid information.

Get medical aid immediately for an abrasive waterjet injury. Tell the physician the cause of the injury, the type of abrasive waterjet work that was done when the accident happened, and the water source.

Stagnant water in the catcher tank can introduce dangerous bacteria into cuts, scrapes, small breaks in the skin, and other types of wounds. Injuries that involve contact with the catcher tank water should receive aid immediately. Injuries that involve contact with the water should be attended to immediately.

Unusual infections with aerophilic microorganisms that occur at lower temperatures have been reported. These can be gram-negative pathogens, such as those found in sewage. Bacterial swabs and blood cultures may be helpful to assist a physician's diagnosis.

An injury caused by high-pressure waterjets can be dangerous. If there is a waterjet injury:

- Get medical aid immediately. Do not wait!

- Tell the physician of the cause of the injury.

- Tell the physician about the type of abrasive waterjet work done when the accident happened and the water source.

- Give this information to medical personnel:

This patient may be suffering from a waterjet injury. Evaluation and management should parallel that of a gunshot injury. The external manifestations of the injury cannot be used to predict the extent of internal damage. Initial management should include stabilization and a thorough neurovascular examination. X-rays can be used to assess subcutaneous air and foreign bodies distant from the site of injury. Injuries to the extremities can involve extensive nerve, muscle, vessel damage, and cause a distal compartment syndrome. Injuries to the torso can involve internal organ damage. Surgical consultation should be obtained. Aggressive irrigation and debridement is recommended. Surgical decompression and exploration may also be necessary. Angiographic studies are recommended pre-operatively if arterial injury is suspected. Bandages with a hygroscopic solution (MgSO4) and hyperbaric oxygen treatment have been used as adjunctive therapy to decrease pain, edema, and subcutaneous emphysema. Unusual infections with uncommon organisms in immunocompetent patients have been seen; the source of the water is important in deciding on initial, empiric antibiotic treatment, and broad-spectrum intravenous antibiotics should be administered. Cultures should be obtained.

Lockout/Tagout

Do standard practices and procedures to shutdown and stop the equipment, isolate it from its energy source(s), and prevent the release of potentially dangerous energy when maintenance and service work is done.

Equipment Grounding Requirements

- Make sure the equipment is correctly grounded in accordance with the national, state, and local codes. Do not remove the prongs from the plug. Always plug into the correct electrical outlet.

- The ground wire gives the electric current a path of least resistance to reduce the risk of electrical shock during a malfunction or breakdown. The machine has an electric cord with an equipment-grounding conductor (EGC) and a ground plug (United States, Canada, and Mexico only). The plug must be connected to a matching outlet that is correctly installed and grounded in accordance with all local codes and ordinances.

- Do not change the plug—if it does not fit the outlet, have the correct outlet installed by a qualified electrician.

- If the EGC is incorrectly connected, it can result in electric shock.

- Contact a qualified electrician or service personnel if the grounding instructions are not understood or if not sure if the equipment is correctly grounded.

- Do not use extension cords with the equipment.

- If the cord is damaged or worn, immediately replace it. Contact OMAX for replacement parts and instructions. The insulation of the EGC is covered with a green or green with yellow-striped surface. If replacement of the electric cord or plug is necessary, do not connect the equipment-grounding conductor to a live terminal. Refer to the equipment-specific wiring configuration.

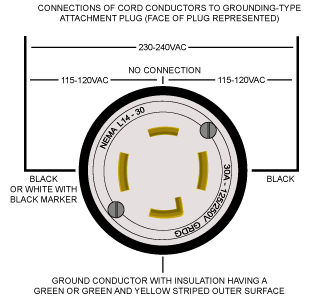

- The equipment is intended to be used on a circuit with an outlet similar to the one shown (United States, Canada, and Mexico only):

Figure 950

- The grounding plug is similar to the one shown (United States, Canada and Mexico only):

Figure 951

- Make sure that the equipment is connected to an outlet that matches the plug configuration.

- The equipment must not be connected to any different type of electric circuit.

- No adapter is available or should be used with this equipment.

- For countries other than the United States, Canada, and Mexico, OMAX does not supply a sufficiently rated industrial-grade plug.

- Contact a qualified electrician or service personnel to install a sufficiently rated industrial-grade plug in accordance with national, state, and local codes.

- A pin and sleeve plug, rated at least 30A, 230V, 2-pole+E (3-wire grounding), IP44 or better, having a first-make last-break protective bonding contact (earthing contact) in accordance with standards IEC 60309-1 and IEC60309-2 can fulfill this requirement.

Figure 952

- The cord must be plugged into a matching outlet that is correctly installed and grounded in accordance with all local codes and ordinances.

Figure 953

Explosive Atmosphere Precautions

Machining certain types of material, such as titanium, with a waterjet can cause sparks. Do not operate the equipment in an explosive environment. Do not let explosive or flammable vapors collect in the area of the equipment.

Removal of Waste Materials

Discard all machining wastes correctly in accordance with all local and federal regulations. Abrasive waterjet machining causes two types of waste: the water used for machining and the solid material that collects in the catcher tank. Although the used garnet abrasive is not dangerous, the waste deposited from the cut material can require special treatment.

In abrasive waterjet machining, high-pressure water with garnet abrasive particles hits and cuts the material. The abrasive grit and eroded particles from the cut material collect and settle at the bottom of the catcher tank until discarded. Different materials can have different requirements to discard them correctly. Always refer to all local and federal regulations. For example, when poisonous materials such as lead or radioactive metals are cut, the correct steps must be taken to discard the poisonous or radioactive water, material debris, and used abrasive garnet; local and federal regulations must be followed. Always refer to the local utility company for sewage or water treatment requirements and procedures to discard waste materials.

Sufficient Shop Ventilation

Make sure there is good airflow in the work area to dissipate gases, vapors, and fumes. The machine contains a large amount of water. The ambient temperature in the shop and of the water can have an effect on water evaporation. To decrease the effect on other equipment in the shop, make sure there is good airflow in the shop. Also, some materials, such as aluminum particles, are known to make hydrogen in water.

When aluminum is cut, the small particles of aluminum dust in the catcher tank react with the water to make flammable hydrogen gases. Usually, hydrogen bubbles to the surface and is released into the shop in safe, low concentrations.

Make sure no ignition sources (open flame or electrostatic discharge) are near the abrasive waterjet system.

Monitor the catcher tank for hydrogen gas bubbles when large quantities of aluminum are cut. The aluminum powder (made from the removed material) and spent garnet collect at the bottom of the catcher tank. The aluminum then reacts with the water and releases hydrogen gas. The hydrogen gas can collect in bubbles in the garnet. The hydrogen gas bubbles are flammable. Keep the garnet levels in the catcher tank low to prevent hydrogen gas bubbles from being collected within the garnet.

Do not smoke near the machine. Keep other sources of ignition or flammable materials near the machine. Be careful when materials that create sparks are cut, such as titanium, which can fire the gases in the catcher tank and cause an explosion. Remove the aluminum powder from the catcher tank before machining materials that spark.

Overpressure Protection

During operation, pump pressure is monitored to prevent an overpressure condition. If the pump pressure increases more than the factory-set maximum pressure limit, the safety relief valve starts and stops the pump.

Electrical Protection

The equipment controller includes short circuit, overcurrent, and thermal protection for the pump motor.

Electrical Disconnect/Emergency Machine Off (EMO)

An electrical disconnect/emergency machine off (EMO) switch is used to remove the primary AC electrical supply from the machine. To isolate the machine from its electrical supply, always unplug the primary AC supply power cord from its electrical supply outlet.

Safety Lid

The lid of the equipment has a safety interlock to prevent waterjet operation when the lid is open.

Safety Legend

The safety signal word panels and paragraph notifications can be shown throughout this and other documentation. Each gives the safety issue identification and recommended actions to prevent the risk. Be alert! Follow the recommended safety steps, procedures, and precautions to prevent injury or damage to the equipment.

Identifies a dangerous situation that could result in death or serious injury if not avoided.

Identifies a dangerous situation that could result in minor or moderate injury if not avoided.

Identifies situations that are important but not dangerous or related to physical injury; for example, messages related to property damage.

Used to give information, emphasize a point, or tips for easier operation.

REQUIRED TOOLS

The following table contains a list of tools with the appropriate sizes needed to prepare the equipment for storage.

Customer Tools

These tools are not provided by OMAX or included with the equipment.

| Icon | Tool | Size(s) |

|---|---|---|

|

|

Open-end wrench | 5/8 in., 19 mm |

|

Ultrasonic cleaner |

|

|

Clean, dry, compressed air | |

|

Ball-end hex wrench | 4 mm |

|

Water spray nozzle | |

|

Shop towels | |

|

Torque wrench | 25 in-lb (3 N•m) |

|

Hex socket driver | 4 mm |

|

|

Desiccants, activated, type 2 P/N 200836 |

|

|

Flat screwdriver | |

|

Bucket |

OMAX Tools

The following table contains a list of tools provided by OMAX. These tools are included with the equipment.

| Icon | Tool | Size(s) |

|---|---|---|

|

Seal removal tool P/N 316852 |

REFERENCES

Documents

The following table contains documents associated with these instructions. Documents are located in KnowledgeBase Resources at knowledgebase.omax.com.

| Part Number | Title |

|---|---|

| 401420 | Installation, ProtoMAX |

| 401434 | Operation, ProtoMAX |

| 401440 | Maintenance, ProtoMAX |

| 401527 | Drain Water Filter Tank, ProtoMAX |

| 401657 | Drain Water Filter Tank, ProtoMAX, CE |

Videos

Videos associated with these instructions are located in KnowledgeBase Videos at knowledgebase.omax.com.

- ProtoMAX Shutdown

- Change the Water Filter

- Prepare the Pump for Maintenance

- Install the ProtoMAX

- ProtoMAX Startup

DOCUMENT SCOPE

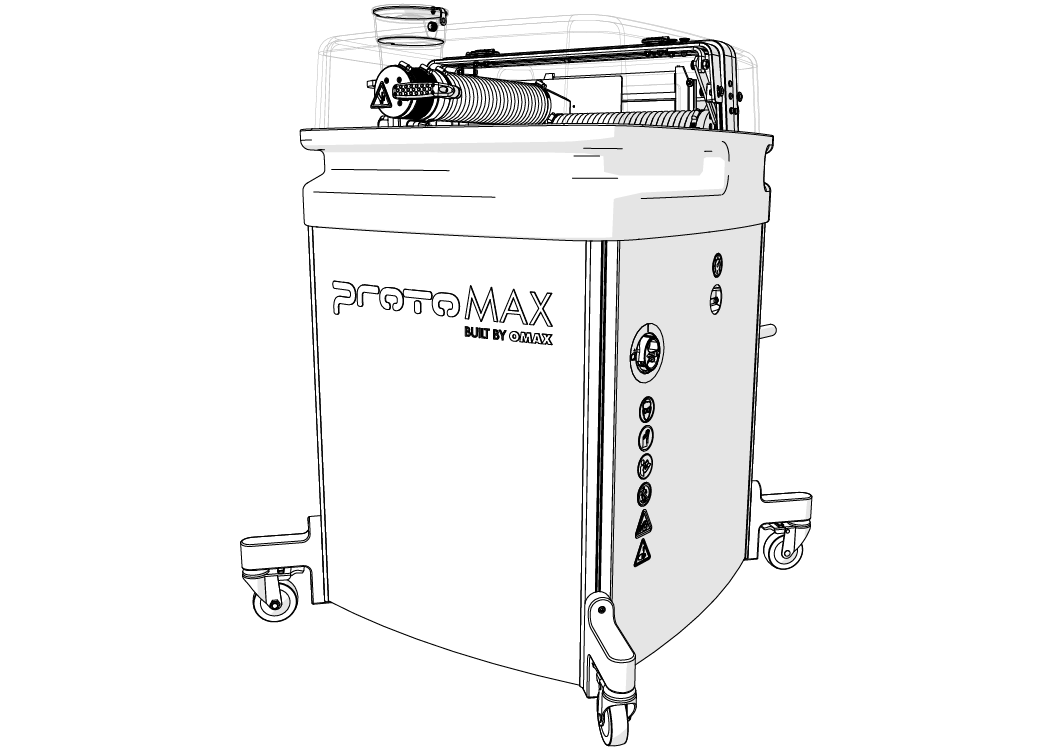

This document contains the procedures for preparing the ProtoMAX for storage longer than one month.

OVERVIEW

OMAX recommends specific procedures for the ProtoMAX when storing the machine for longer than one month during school breaks, vacations, and idle time. Follow the procedures to prevent abrasive from hardening inside the machine, high-pressure tube failure, and other damage.

STORING ProtoMAX FOR LONGER THAN ONE MONTH

| 1. | Follow the shutdown procedure (see 401434 Operation, ProtoMAX and the ProtoMAX Shutdown video, located at knowledgebase.omax.com ). |

| 2. | Follow the Clean the ProtoMAX procedure (see 401440 Maintenance, ProtoMAX and see knowledgebase.omax.com, search for "clean"). Continue with the instructions. |

The results from searching “clean” include the following primary tasks to clean the ProtoMAX.

- Remove the Accumulated Garnet

- Clean the Garnet bins

- Clean the Lid

- Clean the Cutting Stage

- Clean the Cable Track

- Clean the Catcher Tank Filters and Drains

- Clean the Catcher Tank

- Clean the Frame

- Clean the Side panels

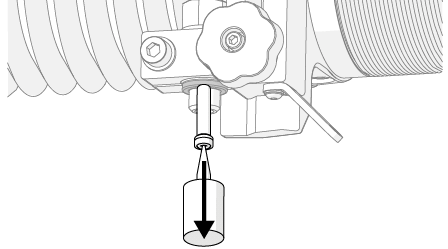

Drain the Water Filter Tank

Drain the water filter tank (See 401527 Drain Water Filter Tank, ProtoMAXand the Clean the Drain Water Filter Tank video or401657 Drain Water Filter Tank, ProtoMAX, CE. and the Drain Water Filter Tank CE Guide video, located at knowledgebase.omax.com).

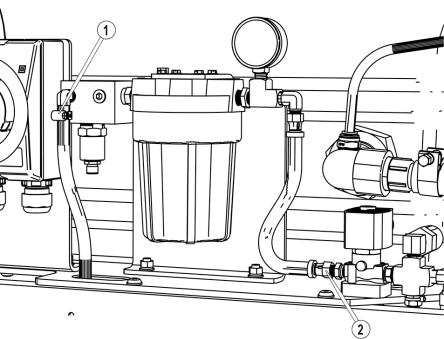

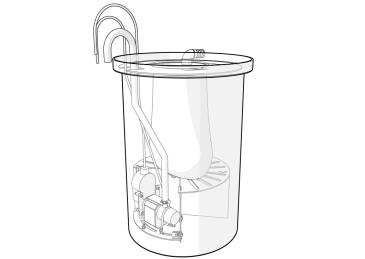

Figure 954

Store the Nozzle

| 1. | Disconnect the abrasive feed tube from the nozzle assembly. |

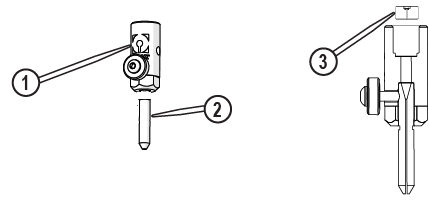

| 2. | Remove the nozzle assembly [2] from the inlet body [1]. |

Figure 955

| 3. | Remove the last chance filter and discard. |

The last chance filter is a consumable item and must be replaced when reactivating the ProtoMAX .

Figure 956

| 4. | Remove the mixing tube [2] and orifice [3] from the nozzle body [1]. |

Figure 957

| 5. | Clean the nozzle body, mixing tube and orifice with white vinegar using an ultrasonic cleaner. |

| 6. | Use clean, dry, compressed air to blow out the remaining moisture from the nozzle components. |

| 7. | Store the nozzle components in a closed drawer/tool box to prevent contamination. |

| 8. | Plug the end of the inlet body [1] with a plastic cap or plastic bag. |

Figure 958

Clean Table and Rear Components

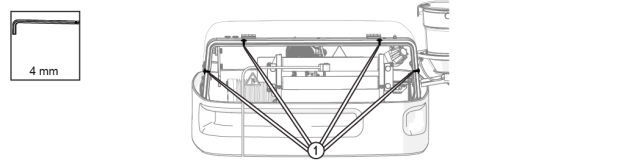

| 1. | Remove the screws and washers [1] securing the rear lid and set aside. |

Figure 959

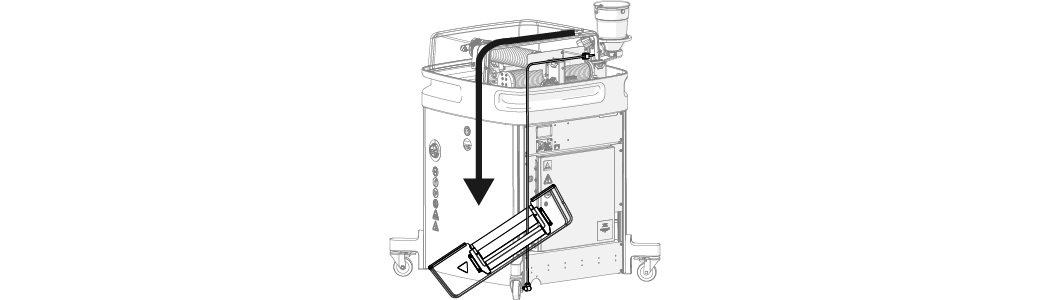

| 2. | Lift the rear lid up, then slide it down the high-pressure plumbing to the floor. |

To prevent scratches to the lid, place it on a soft surface.

Figure 960

| 3. | Rinse off accumulated abrasive and other particles from the components and table inside the ProtoMAX. |

Avoid spraying the black X and Y motor covers. Use a damp microfiber cloth to wipe off the motor covers. Spraying the motor covers with water may cause leakage into the motor housing which could lead to premature wear of the motor housing and cable connections

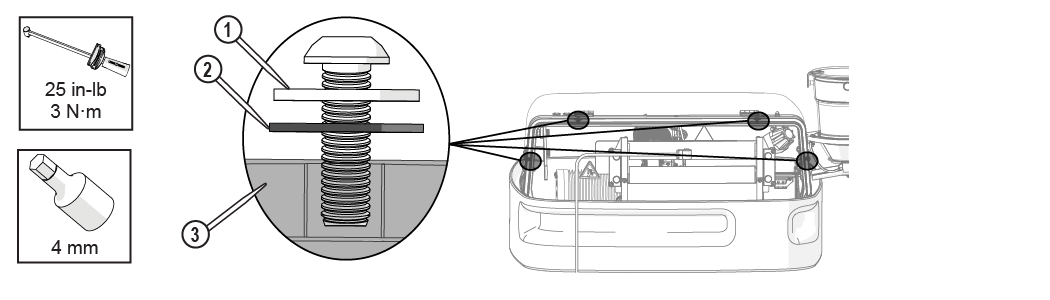

| 4. | Reattach the rear lid and secure with the screws and washers (x 4). |

To prevent damage to the lid [3], ensure the rubber washer [2] is placed between the lid and the metal washer [1]. Do not overtighten the screw.

| 5. | After cleaning the catcher tank and interior components, use a wet/dry vacuum to remove remaining water. Leave the water drained. |

| 6. | Place humidity absorbing (desiccant) packs in the tank. |

Use sufficient number of packs for an approximate 11 cubic feet of enclosed tank and lid area (2 bags).

Clean the Hopper

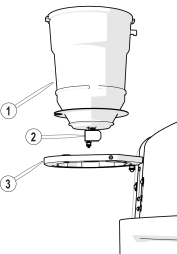

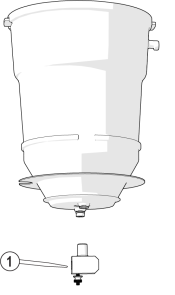

| 1. | Disconnect the abrasive feed tube [1] from the abrasive orifice. Leave it hanging from the roll bar. |

Figure 962

| 2. | Use clean, dry, compressed air to blow abrasive out of the abrasive feed tube. |

| 3. | Remove the hopper splash guard. |

Figure 963

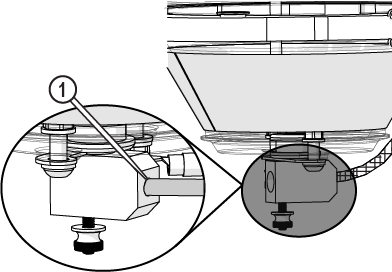

| 4. | Remove the hopper ground strap [1]. |

Figure 964

| 5. | Remove the hopper assembly [1] including the hopper feed block [2] from the hopper support plate [3]. |

Figure 965

| 6. | Completely empty and discard the abrasive from the hopper assembly. |

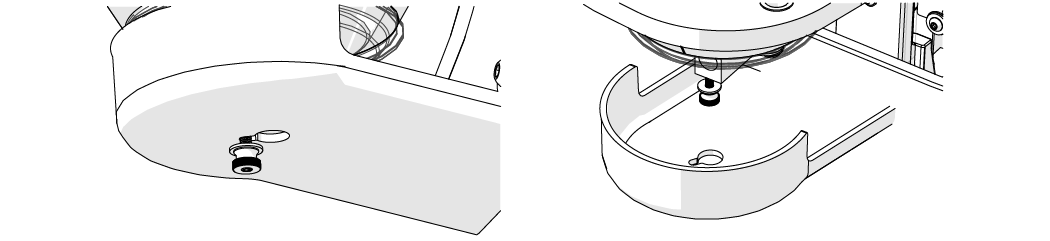

| 7. | Remove the abrasive feed block [1] from the hopper assembly. |

Figure 966

| 8. | Wipe out the hopper assembly with a clean, dry cloth. |

| 9. | Use clean, dry, compressed air to completely blow out all debris, clumps, or clogs from the abrasive feed block. |

Remove Water

Remove the water from the system if the ProtoMAX is inactive for more than a few months (summer or semester break) and/or over a winter break where there is any chance of temperatures below 32 °F (0 °C).

Remove the Water Filter

See 401440 Maintenance, ProtoMAX, and the Change the Water Filter video, located at knowledgebase.omax.com.

Discard the used water filter and replace with a new filter when taking the system out of storage. Remove all water from the filter canister.

Blow Out Water from the Low-Pressure Manifold

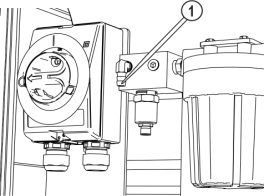

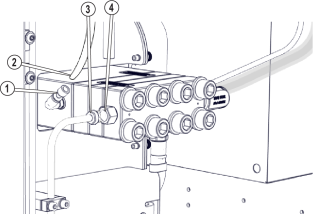

| 1. | Loosen the band clamp [1] from the hose on the incoming water supply and remove the hose. |

| 2. | Disconnect the hose [2] (Figure 967) from the solenoid valve and put the loose hose end in a bucket. |

| 3. | Blow clean, dry, compressed air into the manifold inlet [1] and blow water through the plumbing and into the bucket. |

| 4. | Reconnect the hose to the incoming water supply (Figure 967). |

| 5. | Reconnect the hose to the solenoid valve(Figure 967). |

Blow Water Out of the Pump

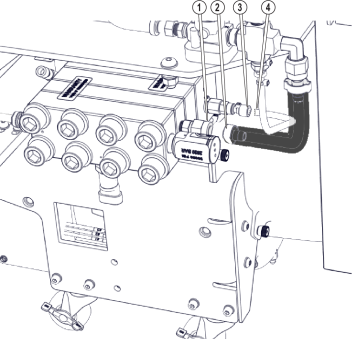

| 1. | Disconnect the high-pressure components (see 401440 Maintenance, ProtoMAX and the Prepare the Pump for Maintenance video, located at knowledgebase.omax.com). |

| 2. | Use clean, dry, low pressure (45 psi) compressed air to blow out cooling water at port [1]. |

Do not exceed 45 psi when blowing out air from this port. Using air pressure higher than 45 psi may dislodge interior seals and O-rings.

| 3. | Use clean, dry, high pressure (90 psi or more) compressed air to blow out water at port [2] (Figure 969). |

Install Caps

It is very important to cap all openings. Uncovered openings may allow contaminants into the system. No ports or hoses should be left uncapped.

Install caps or block the openings on all hoses, tubing, and ports that are exposed to the environment (Figure 970) and (Figure 971).

| [1] Outlet cooling port | [2] Outlet cooling hose |

|

[3] High-pressure tubing |

[4] High-pressure port |

| [1] Incoming water port | [2] Incoming water hose |

|

[3] Inlet cooling port |

[4] Inlet cooling tubing |

Reactivate the ProtoMAX Machine

Follow the ProtoMAX install and start-up procedures to reactivate the machine (see 401420 Installation, ProtoMAXand the Install the ProtoMAX video, and 401434 Operation, ProtoMAX and the ProtoMAX Startup video, located at knowledgebase.omax.com).

TECHNICAL SUPPORT

Go to protomax.com for technical support contact information.