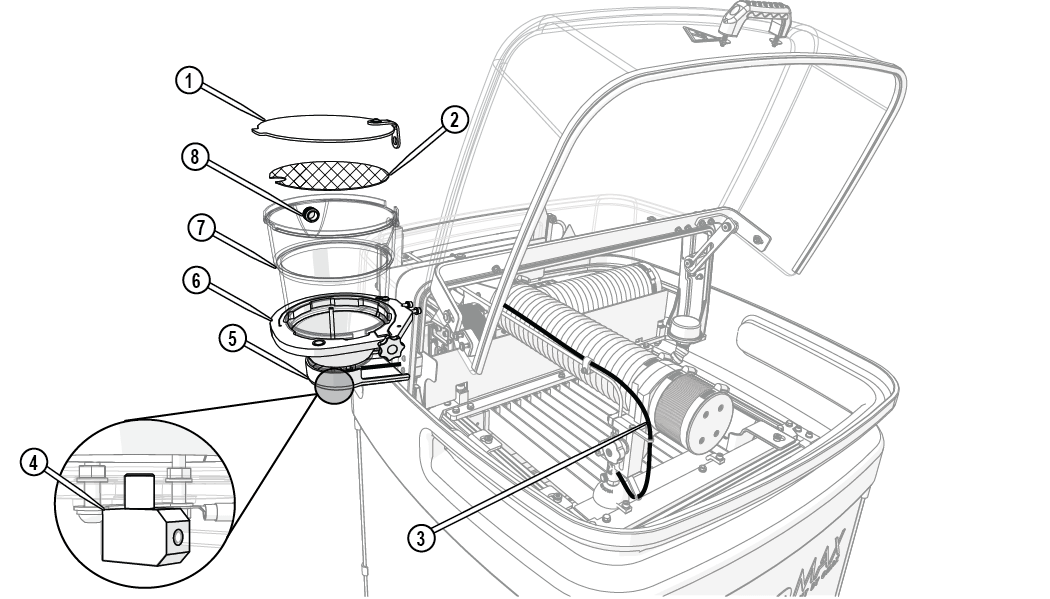

Garnet Abrasive Delivery System

The garnet abrasive delivery system consists of the high-pressure nozzle, garnet abrasive feed system (hopper and feed tube), and high-pressure plumbing. The garnet abrasive hopper lid keeps the garnet abrasive from being contaminated with debris or getting wet. The garnet abrasive screen helps to filter small pieces of debris when filling the hopper that may clog the feed tube or nozzle. When machining a part, the garnet abrasive flows from the hopper to the abrasive waterjet nozzle through the garnet abrasive feed tube.

The garnet abrasive material in the hopper must be kept clean and dry. If moisture enters the hopper, the garnet abrasive material will clump and clog the feed tube, which will require cleaning. Even very small particles of dirt will clog the mixing tube. Always store the garnet abrasive material in a covered, dry location protected from metal chips and other debris.

Figure 375

| [1] Hopper lid | [3] Abrasive feed tube* | [5] Hopper splash guard | [7] Garnet abrasive hopper assembly |

| [2] Garnet abrasive screen | [4] Abrasive feed block | [6] Hopper support plate | [8] Bulk abrasive port |

| * tube routing is for illustration purposes only. | |||

Always use garnet abrasive purchased from OMAX. This high-quality abrasive is more consistent in particle size and contain less dust. Inconsistency in particle size makes it difficult to maintain quality when cutting and increases the likelihood of the mixing tube becoming clogged. When dust is present, static electrical charges can build up, causing the garnet abrasive particles to clump together, hindering the garnet abrasive flow.