Test the ProtoMAX

Before operating the ProtoMAX verify the PC, electrical, and water connections are secure.

Ensure the equipment is properly grounded in accordance with national, state, and local codes. Never remove any prong from the plug. Always plug into the proper electrical outlet. See the ProtoMAX Utilities Requirements document and Safety section for important grounding information. Improper connection can result in a risk of electrical shock. If the electrical outlet is NOT properly grounded, or if in doubt as to whether the tool is properly grounded, contact a qualified electrician or service personnel.

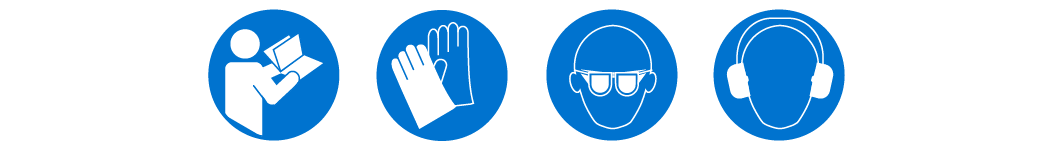

Verify the abrasive feed tube is not connected to the nozzle.

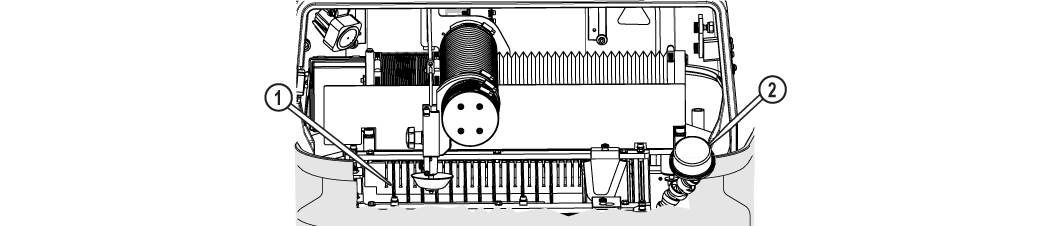

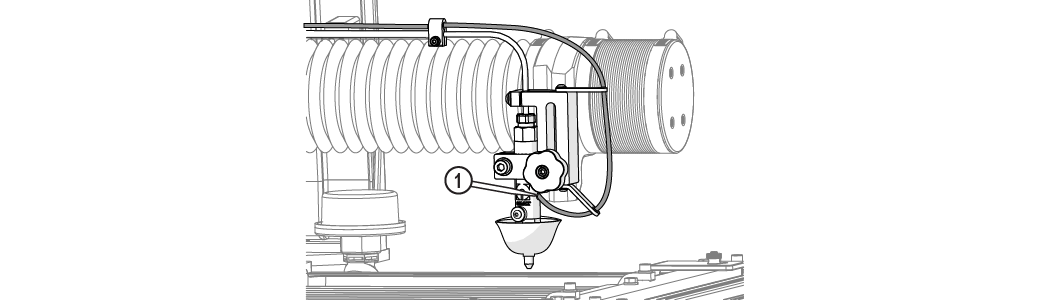

Figure 253

| 1. | Run the Reset Pump test operation. |

The reset pump test runs a 30 second sequence to reset the pump. This test should be done before operating the ProtoMAX for the first time, after changing the nozzle orifice, repairing or replacing the pump, repairing any high pressure plumbing leaks, or when required by a fault or alert message.

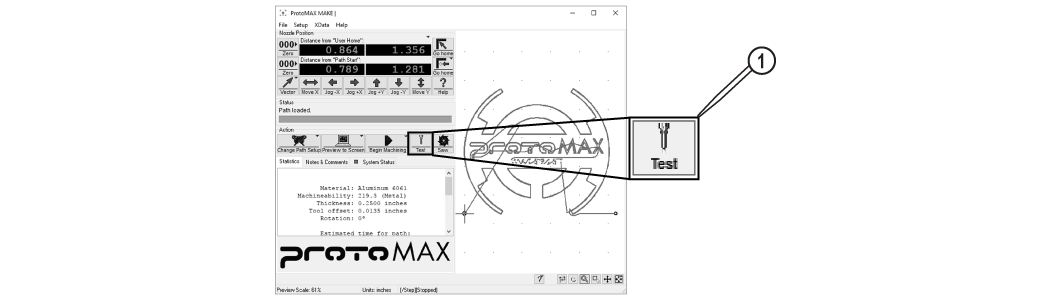

| a. | Open MAKE. |

| b. | Move the nozzle between two slats. |

| c. | Click . |

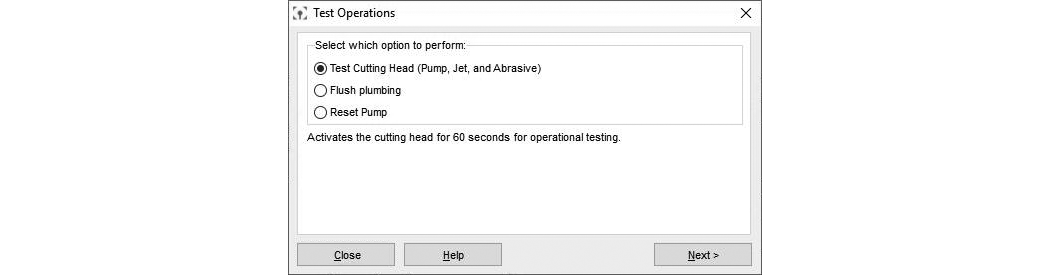

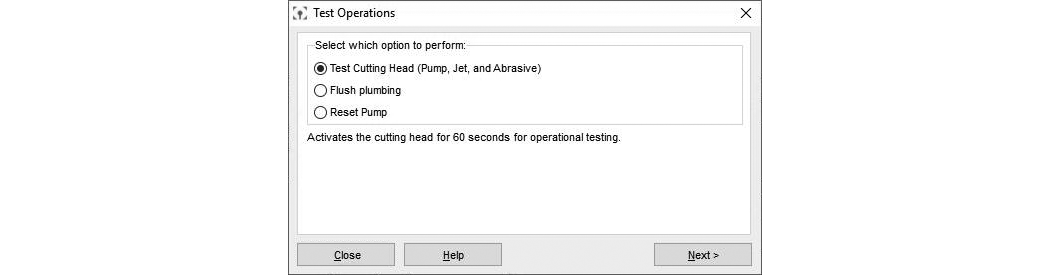

| d. | In Test Operations, select Reset Pump, and click . |

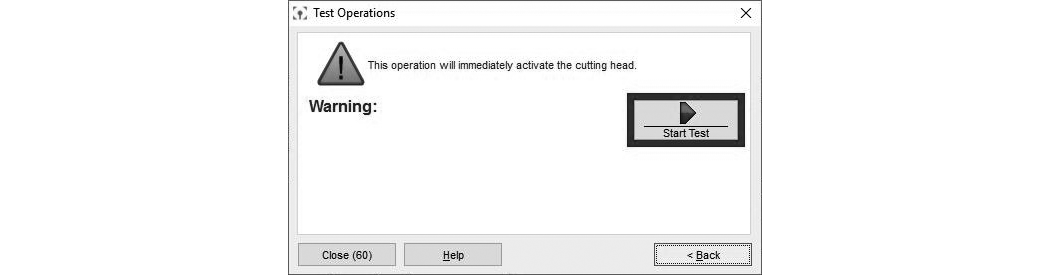

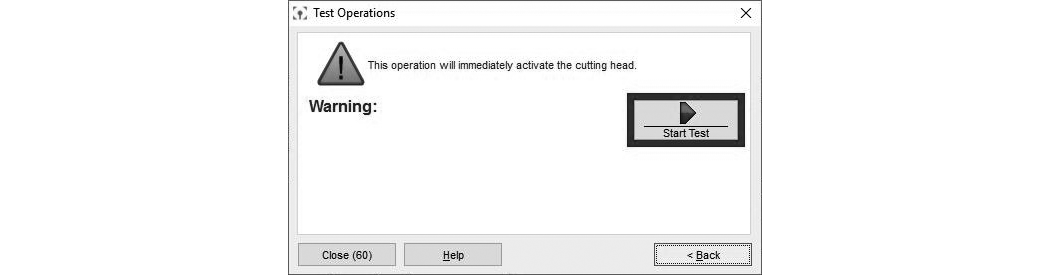

| e. | Click and check the high-pressure plumbing for leaks (the dialog box closes when the test is complete). |

| 2. | Verify the lid safety switch operation. |

The cutting stage lid has a built-in safety interlock to halt all cutting operations (pauses MAKE, stops stage motion, and turns off the pump) when the lid is opened.

| a. | In Test Operations, select Test Cutting Head (Pump, Jet, and Abrasive), and click . |

| b. | Click . |

| c. | Open the lid to verify the test stops (the pump turns off, MAKE pauses, and stage motion stops). |

| d. | Close the lid. |

| e. | Verify the X-axis and Y-axis moves. |

| 3. | Test the nozzle without abrasive. |

| a. | Open and secure the lid. |

Use care when opening or closing the lid to avoid injury. Never let the lid free-fall. Keep hand, fingers, or body parts away from the side of the table when closing the lid.

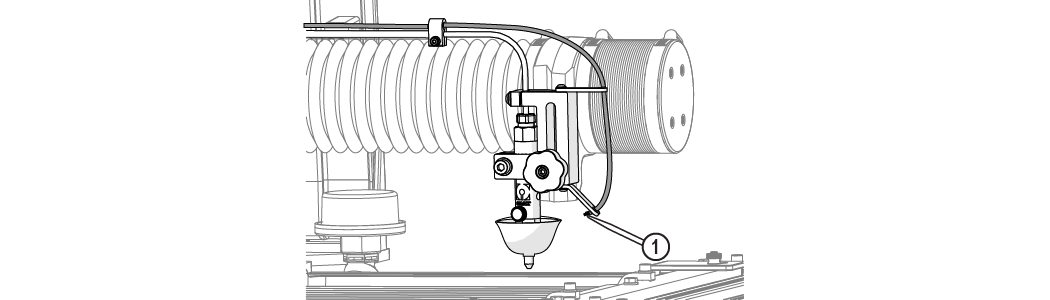

Figure 254

Verify the abrasive feed tube is not connected to the nozzle.

Figure 255

| b. | Position the nozzle in the center of the tank, between two slats. |

Figure 256

| c. | Close the lid. |

Use care when opening or closing the lid to avoid injury. Never let the lid free-fall. Keep hand, fingers, or body parts away from the side of the table when closing the lid.

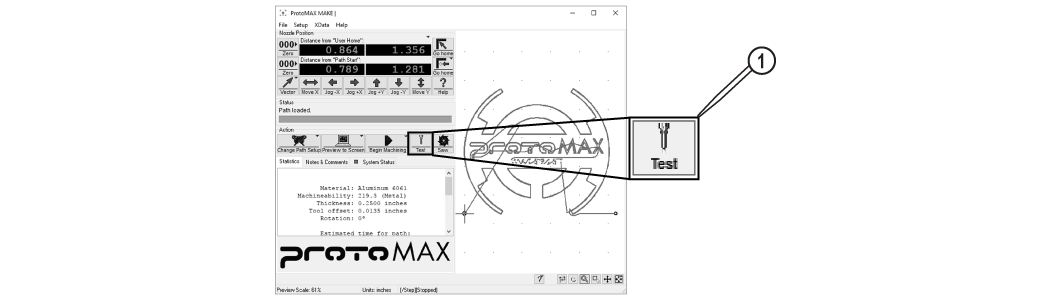

| d. | Click [1]. |

Figure 257

| e. | In Test Operations, select Test Cutting Head (Pump, Jet, and Abrasive), and click . |

Figure 258

| f. | Click . |

Figure 259

| g. | Click when the test is complete. |

| 4. | Test the nozzle with abrasive. |

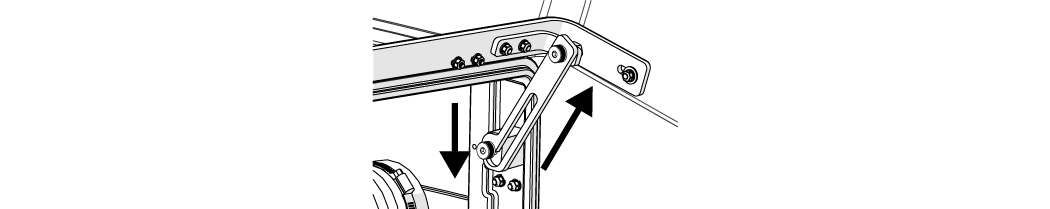

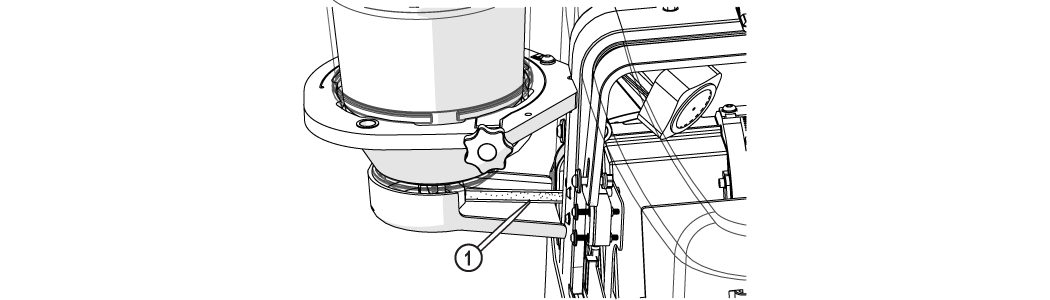

| a. | Insert the abrasive feed tube into the garnet abrasive inlet [1]. |

Figure 260

| b. | Click Test [1]. |

Figure 261

| c. | In Test Operations, select Test Cutting Head (Pump, Jet, and Abrasive), and click . |

Figure 262

| d. | Click . |

Figure 263

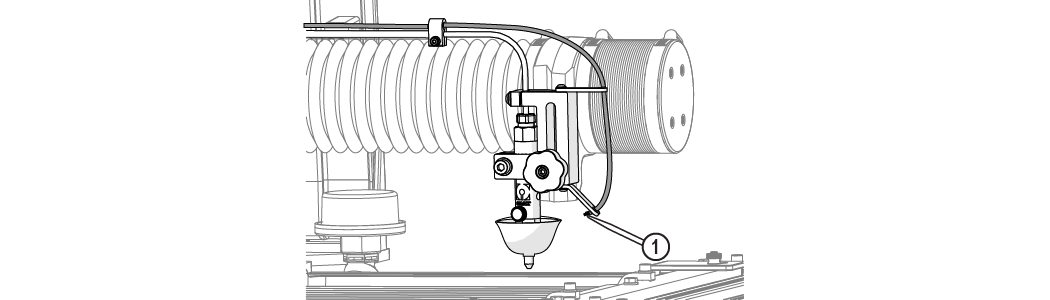

| e. | Observe the garnet abrasive tube [1] to verify abrasive is flowing. |

Figure 264

| f. | Click when the test is complete. |

The nozzle test automatically stops and closes the Test in progress ... window after 60 seconds.