Install the Nozzle

Do not install the nozzle before performing the initial system flush.

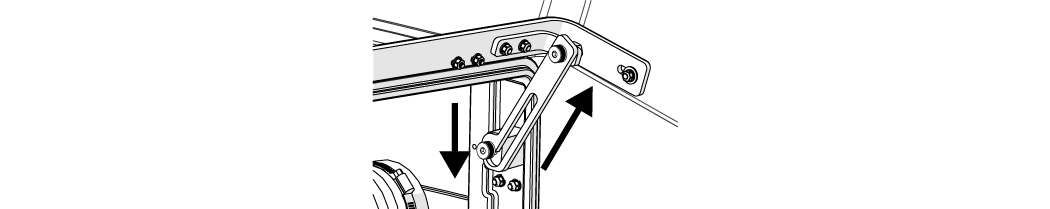

| 1. | Open and secure the lid. |

Use care when opening or closing the lid to avoid injury. Never let the lid free-fall. Keep hand, fingers, or body parts away from the side of the table when closing the lid.

Figure 241

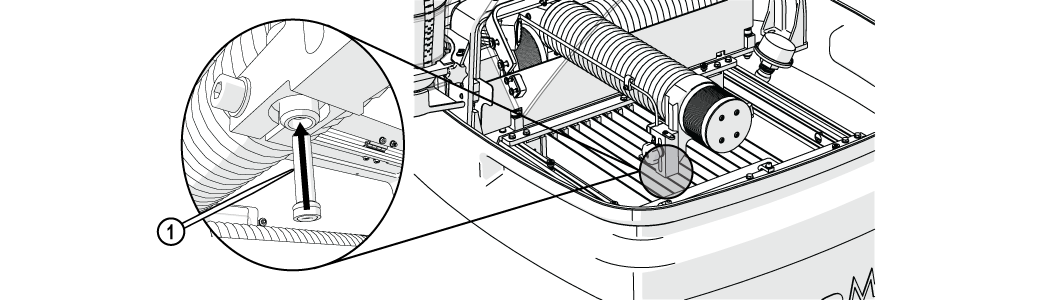

| 2. | Place a piece of cardboard or other material on top of the slats to keep small parts from falling into the tank. |

| 3. | Raise the Z-axis plate. |

Hold the inlet body when loosening the hand knob. Do not let the inlet body fall and strike the cutting deck slats. Damage to the inlet body may occur, which may cause leaks.

| 4. | Install the nozzle filter [1] into the inlet body. |

Figure 242

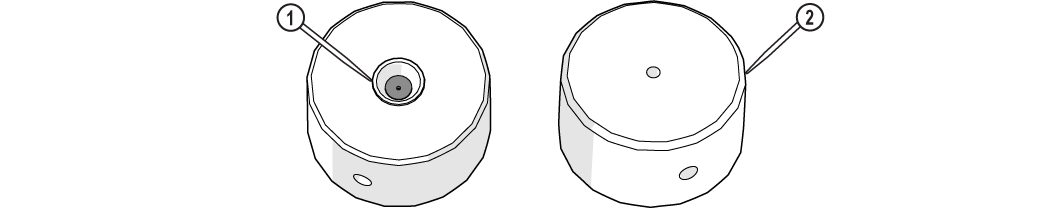

| 5. | Carefully remove the protective cap from the nozzle assembly. |

Always orient the orifice assembly so the brass [1] is visible from the top of the nozzle body. Inserting the orifice assembly in nozzle body in the incorrect orientation [2] may cause damage to the orifice assembly.

Figure 243

| 6. | Insert the orifice assembly [1] into the nozzle body and adjust the orifice to ensure the it is seated correctly in the chamber bore [2]. |

Figure 244

Do not use a brush or cotton swab or foam-tipped applicator to apply lubricants because they may leave fibers and clog the nozzle.

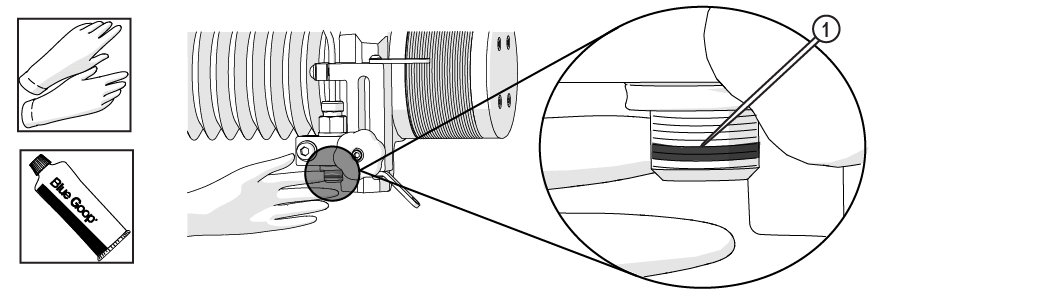

| 7. | Apply a light coat of Blue Goop to the second and third threads [1] of the inlet body, then spread the lubricant evenly around the inlet body threads. |

Figure 245

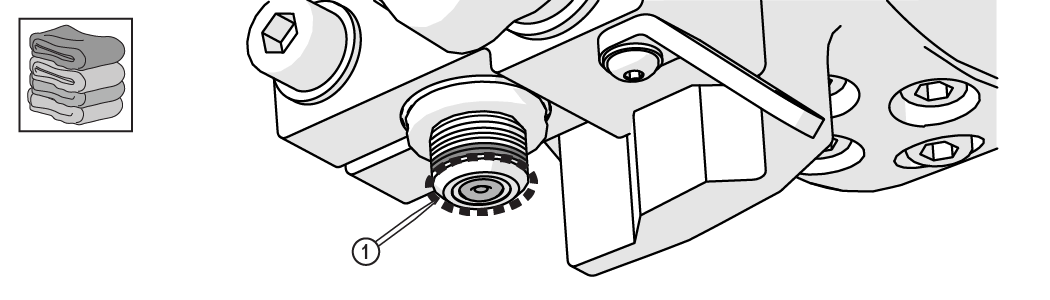

| 8. | Wipe the excess Blue Goop from the end of the inlet body [1]. |

Figure 246

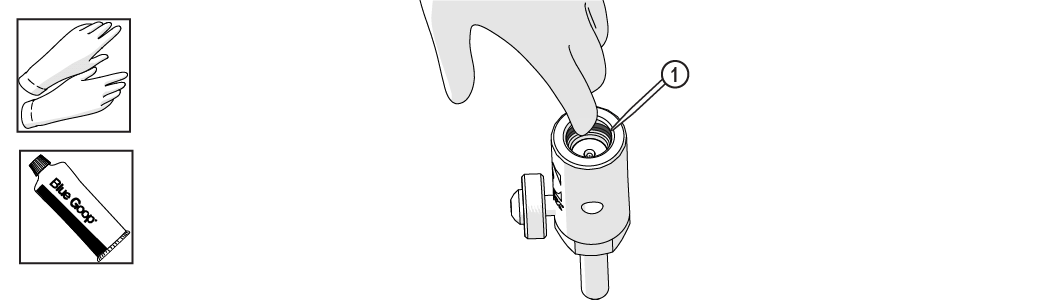

| 9. | Apply a light coat of blue goop to the first and second nozzle body threads [1], then spread the lubricant evenly around the nozzle body threads. |

Figure 247

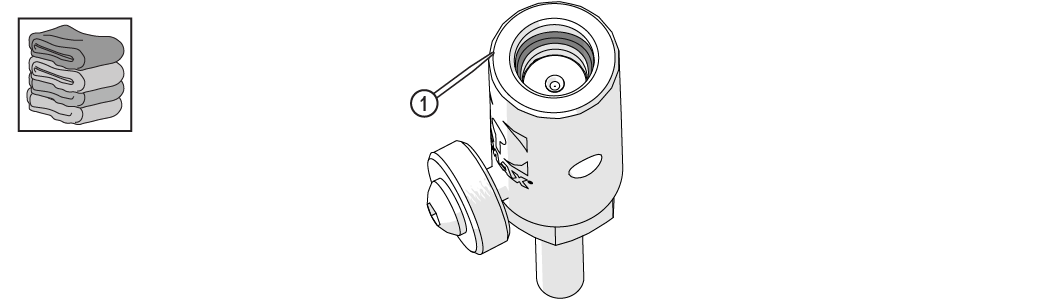

| 10. | Wipe the excess Blue Goop from the end of the nozzle body [1]. |

Figure 248

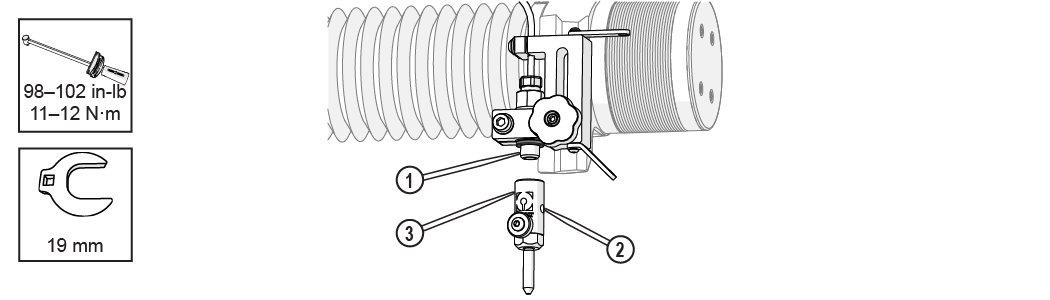

| 11. | Attach the nozzle [3] to the inlet body [1]. |

Ensure the garnet abrasive inlet [2] points towards the front of the table. Move the Z-axis to the back of the cutting deck (+Y direction) prior to tightening.

Figure 249

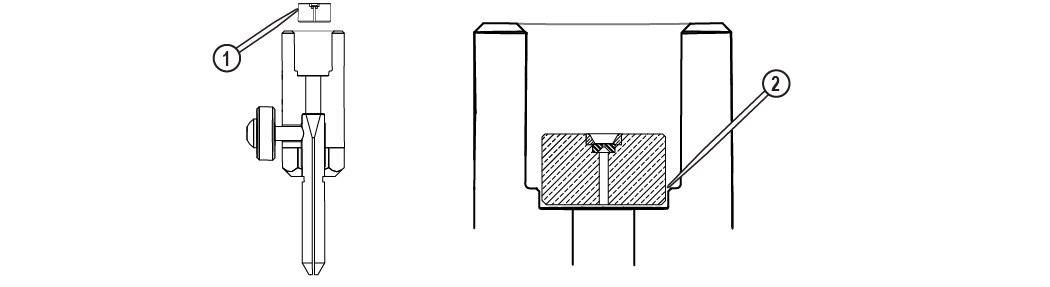

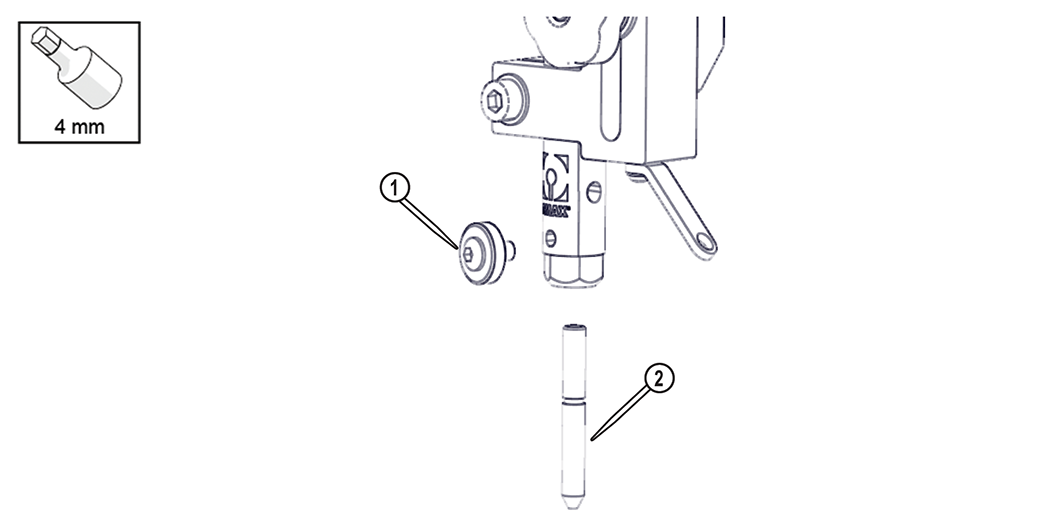

Remove the thumb screw [1] and mixing tube [2] from the nozzle body if necessary to fit the torque wrench prior to tightening. Hold onto the mixing tube [2] so that it does not drop out of the nozzle body when the thumb screw [1] is removed.

Figure 250

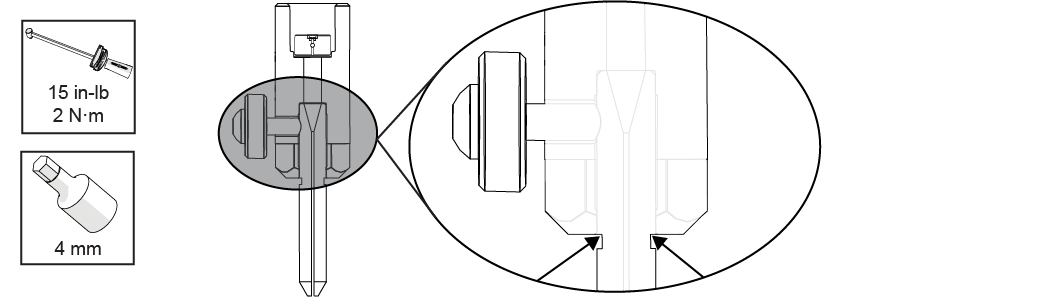

| 12. | Verify the mixing tube is properly seated into the nozzle body and the thumb screw is tightened. |

Figure 251

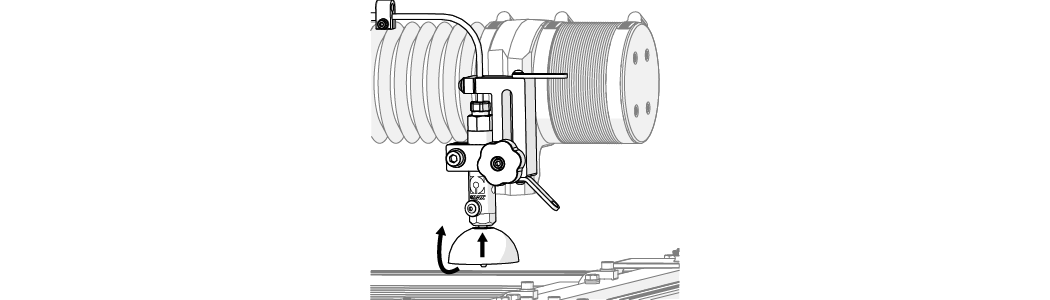

| 13. | Place the nozzle splash guard onto the mixing tube, then fold the splash guard cup. |

Figure 252

| 14. | Close the lid. |

Use care when opening or closing the lid to avoid injury. Never let the lid free-fall. Keep hand, fingers, or body parts away from the side of the table when closing the lid.